Environment-protecting water-based all-plastic track construction method and environment-protecting water-based all-plastic track

A construction method and an environment-friendly technology, which is applied to the construction method of the environment-friendly water-based all-plastic runway and the field of the environment-friendly water-based all-plastic runway, can solve the problems of soil environment and groundwater pollution, and the adhesive is prone to cracking, etc., so as to achieve firm bonding and good performance. Resilience and impact absorption, the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

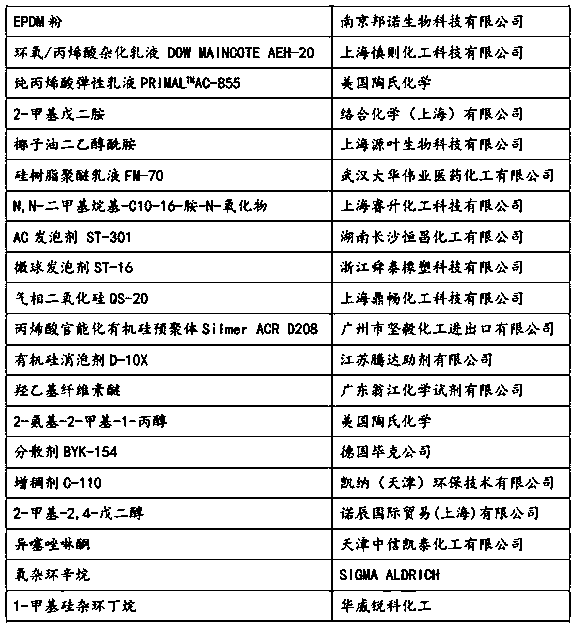

[0064] 1) Preparation of water-based all-plastic runway adhesive Ⅰ:

[0065] Water-based all-plastic runway adhesive I is made by mixing component A and component B at a mass ratio of 100:3.5, wherein component B is 2-methylpentamethylenediamine, and component A is prepared by the following process,

[0066] P1. Add 0.3kg of dispersant BYK-154, 1kg of 2-methyl-2,4-pentanediol, 2kg of isothiazolinone and 0.175kg of silicone defoamer D-10X to 23.5kg of deionized In water, stir at a speed of 500rpm for 10min;

[0067] P2. Continue to add 1 kg of hydroxyethyl cellulose ether, and disperse for 25 minutes at a speed of 300 rpm;

[0068] P3. Continue to add 40kg of acrylic polymer emulsion, 4kg of acrylic functionalized silicone prepolymer Silmer ACRD208 and 1kg of 2-amino-2methyl-1-propanol, and disperse at a speed of 500rpm for 25min; The polymer emulsion is made by mixing epoxy / acrylic hybrid emulsion DOW MAINCOTE AEH-20 and pure acrylic elastic emulsion PRIMAL™ AC-855 at a mass...

Embodiment 1

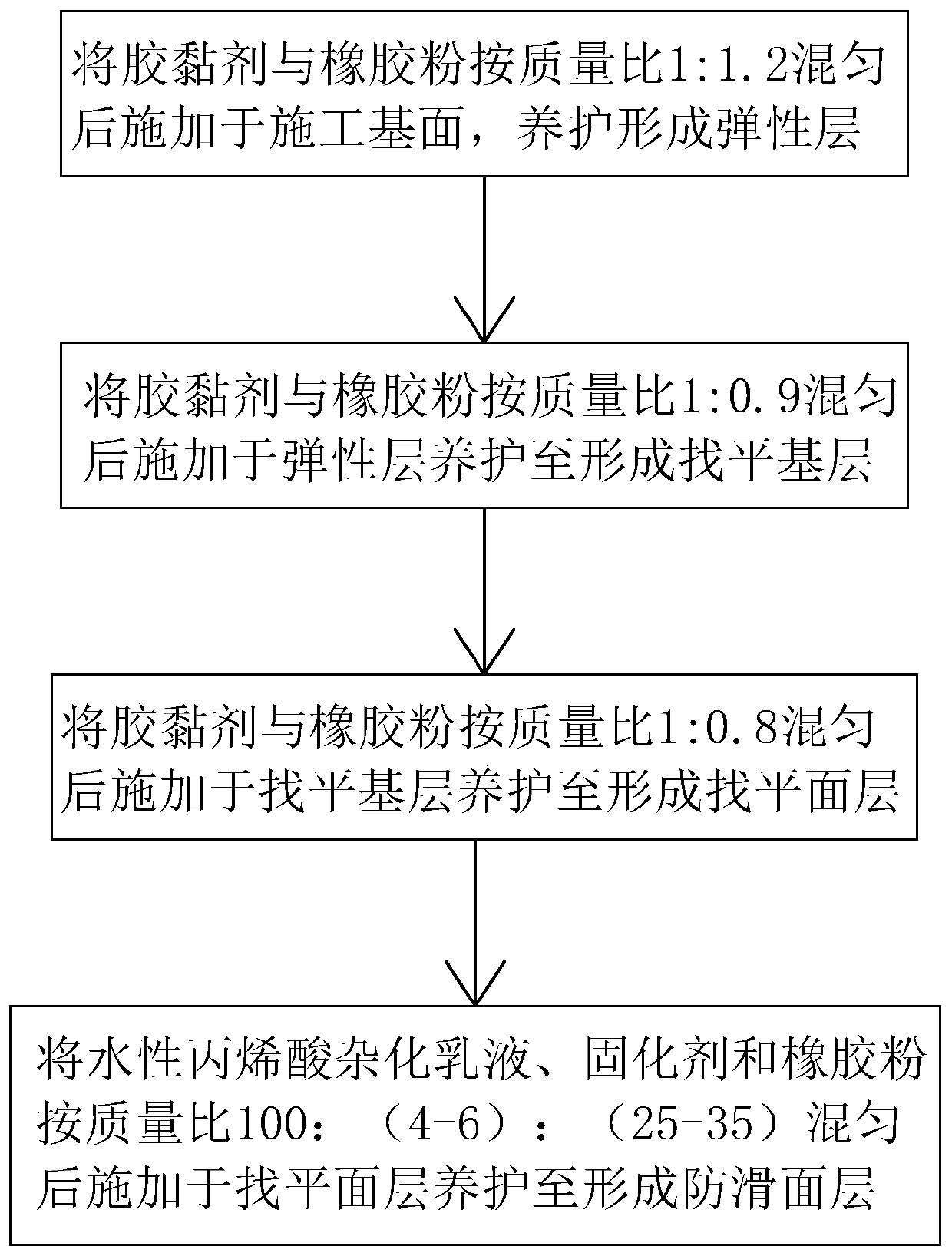

[0083] An environment-friendly water-based all-plastic runway construction method, with reference to figure 1 , which includes the following steps:

[0084] S1. Mix the water-based all-plastic runway adhesive I and EPDM powder evenly according to the mass ratio of 1:1.2, then scrape the construction base surface, use the special material rake disclosed by CN108166355A and CN207904720U to pull the applied mixture into strips, and maintain it until Dry to form an elastic layer with striped lines, and control the thickness of the elastic layer to 2mm;

[0085] S2. Mix the water-based all-plastic runway adhesive Ⅰ and EPDM powder evenly according to the mass ratio of 1:0.9, then scrape them on the elastic layer, and use the leather rake to make the mixture fill the strip-shaped gaps of the elastic layer, and maintain it until dry to form a leveling Base layer, control leveling base layer thickness to 1mm;

[0086] S3. After mixing the water-based all-plastic runway adhesive Ⅰ an...

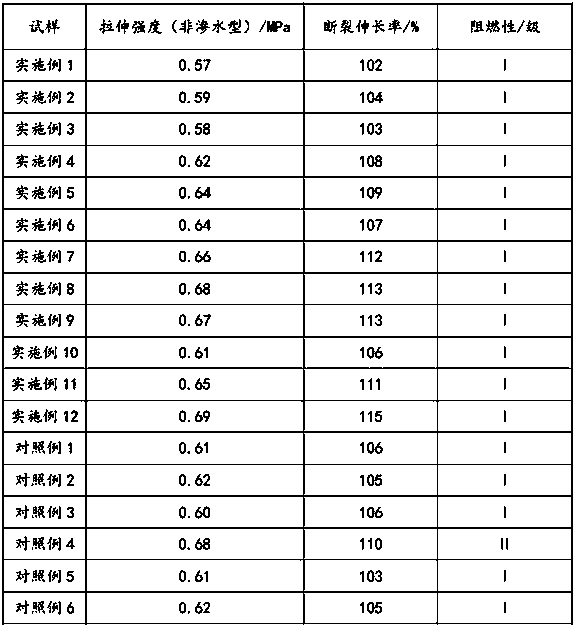

Embodiment 2

[0089] An environment-friendly water-based all-plastic runway construction method, based on Example 1, the difference between this example and Example 1 is:

[0090] In step S1, control the thickness of the elastic layer to 1.5mm; in step S2, control the thickness of the leveling base to 1.5mm; in step S3, control the thickness of the leveling layer to 2.0mm; in step S4, epoxy / acrylic hybrid emulsion The mass ratio of DOW MAINCOTE AEH-20, 2-methylpentamethylenediamine and EPDM powder is 100:5:30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com