Method for preparing nitrogen-sulfur double-doped graphene negative electrode material by low-temperature molten salt method

A graphene negative electrode and low-temperature molten salt technology, applied in the direction of graphene, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of time-consuming and low yield, and achieve low cost and reliable Strong controllability and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

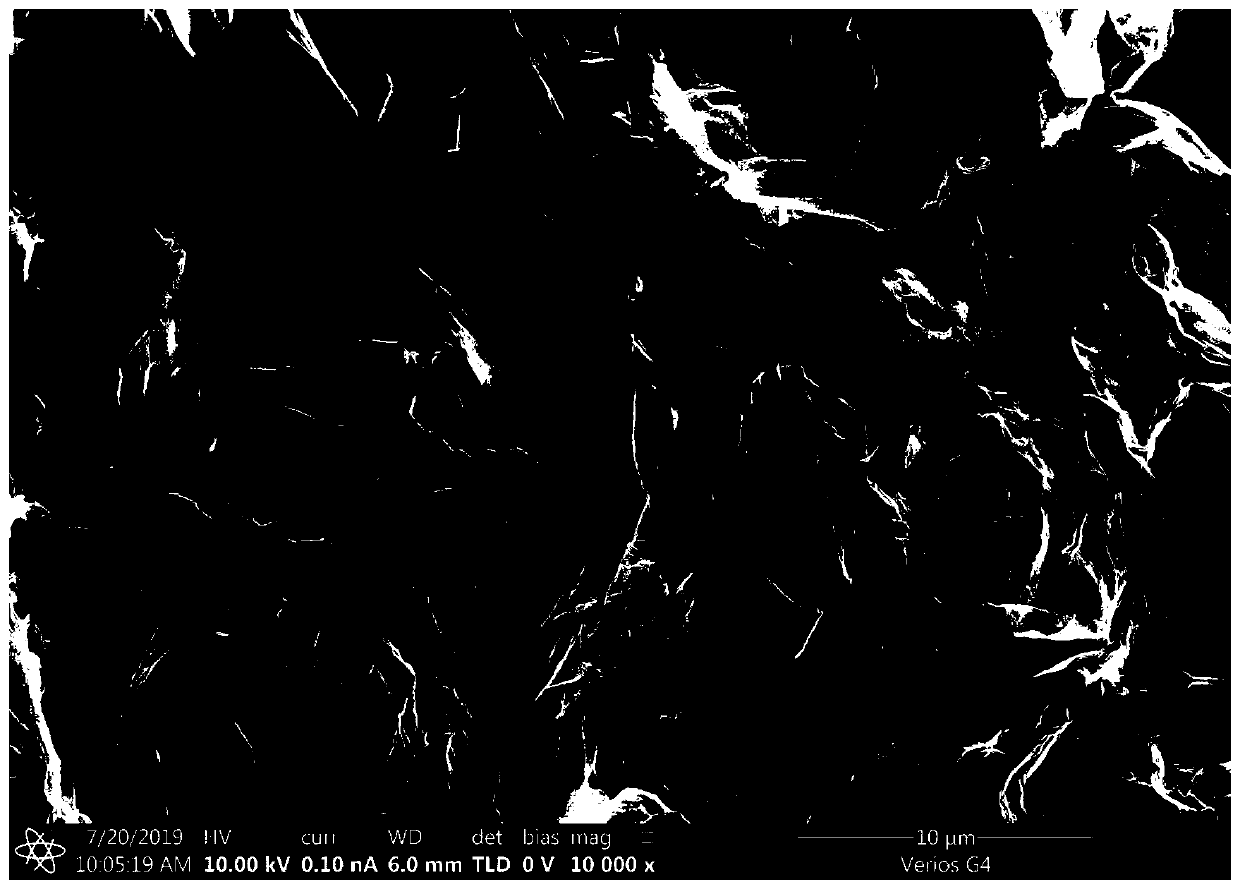

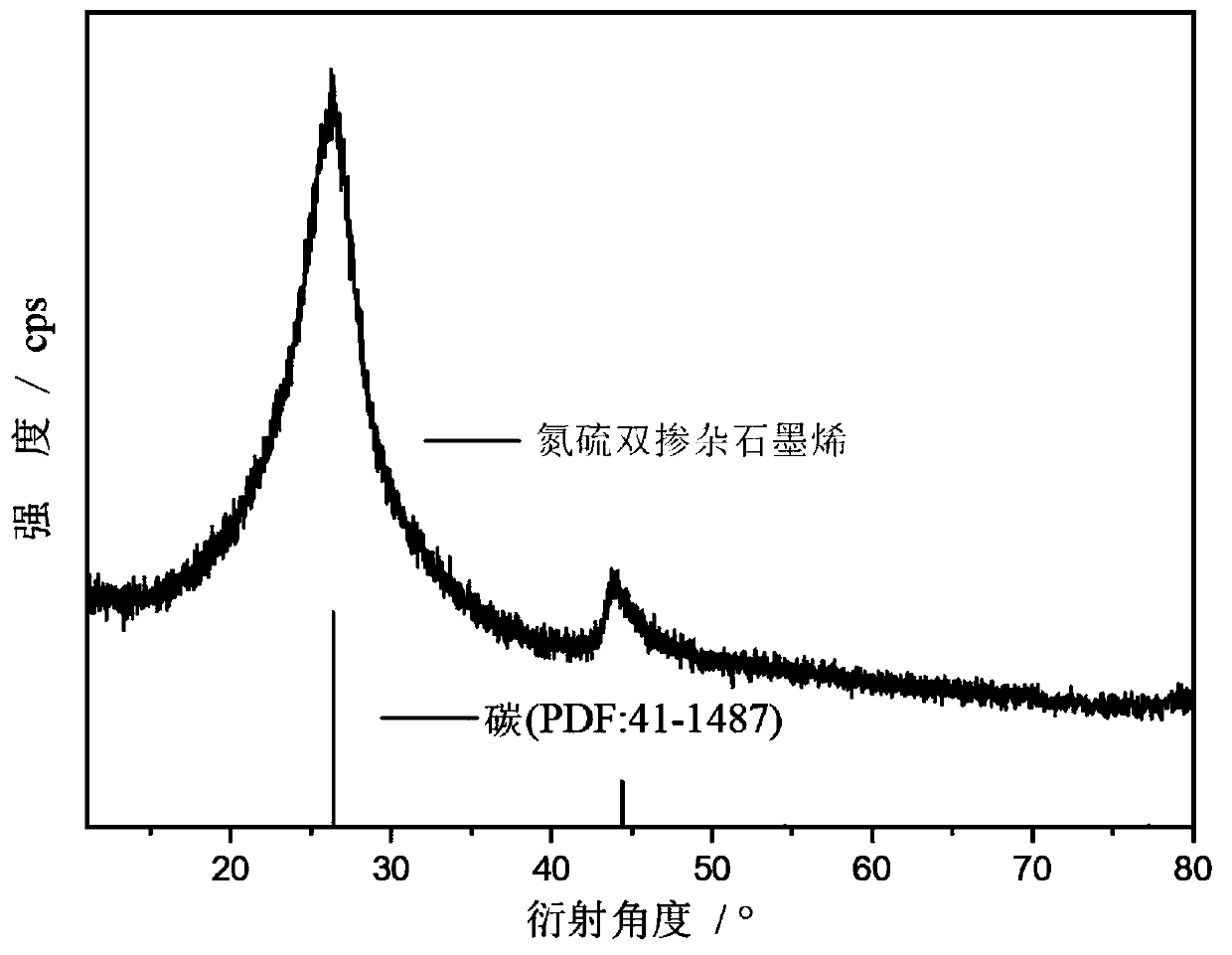

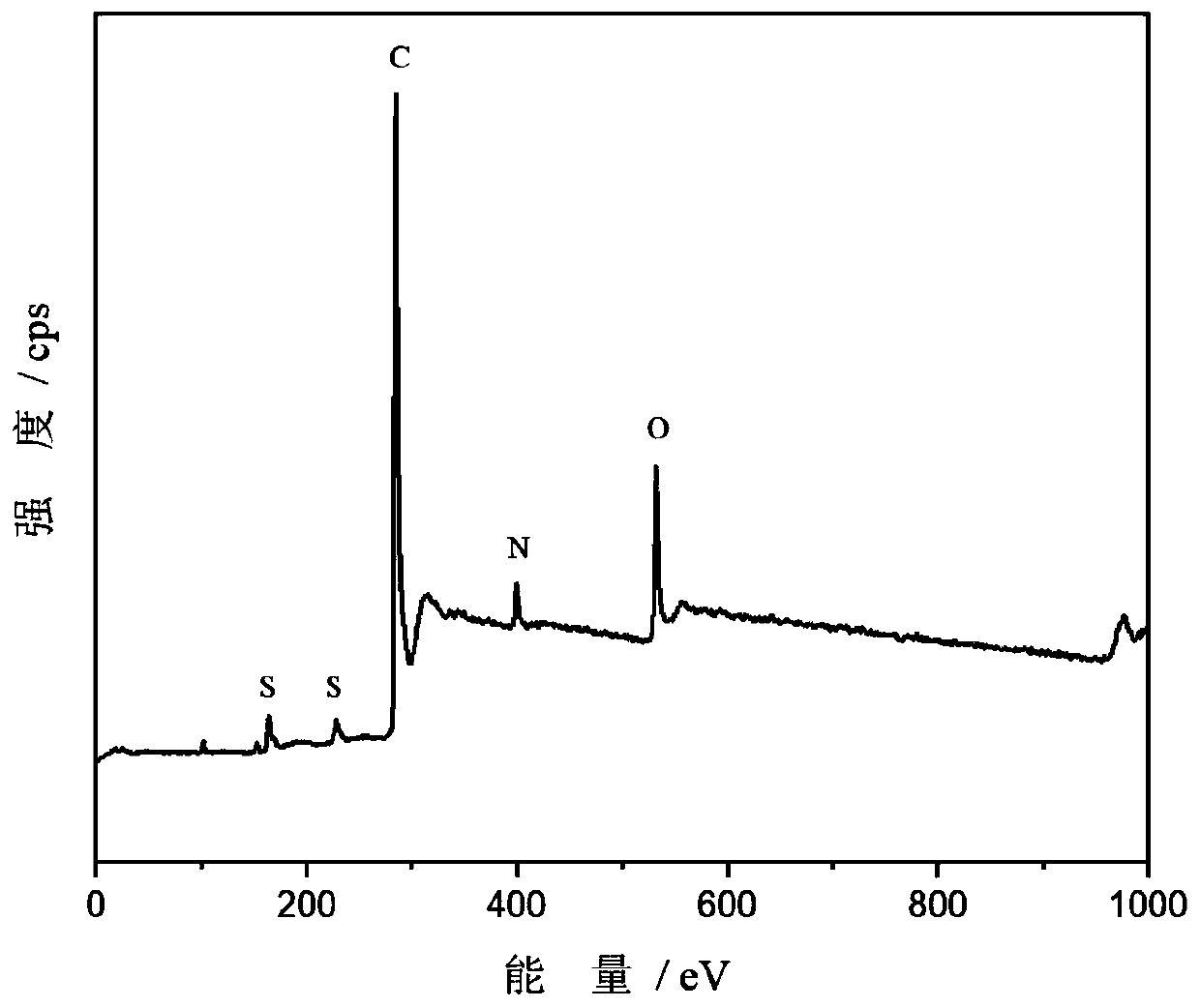

[0030] The low-temperature molten salt method of the present application prepares nitrogen-sulfur double-doped graphene, applies it to the negative electrode material of lithium-ion batteries, and performs electrochemical performance tests on it. The steps of the method in this embodiment are as follows:

[0031] (1) 0.3g graphene oxide is ultrasonically dispersed in deionized water at room temperature, and 8g potassium thiocyanate is dissolved in deionized water;

[0032] (2) Add potassium thiocyanate solution to the dispersion of graphene oxide, and stir the mixed solution at room temperature for 30 minutes, mix well and then dry at 100°C to obtain a composite of graphene oxide and potassium thiocyanate thing;

[0033] (3) Transfer the compound obtained in (2) to a tube furnace filled with inert gas, heat it to 175°C at a heating rate of 5°C / min, and hold the temperature for 12h to obtain the product, which is cooled to Take out after room temperature;

[0034] (4) The rea...

Embodiment 2

[0043] (1) 0.3g graphene oxide is ultrasonically dispersed in deionized water at room temperature, and 8g thiourea is dissolved in deionized water;

[0044] (2) Add the thiourea solution to the graphene oxide dispersion, and stir the mixed solution at room temperature for 30 min, mix well and then dry at 100°C to obtain a composite of graphene oxide and thiourea;

[0045] (3) Transfer the compound obtained in (2) to a tube furnace filled with inert gas, heat it to 180°C at a heating rate of 5°C / min, and hold the temperature for 12h to obtain the product, which is cooled to Take out after room temperature;

[0046] (4) The reactant obtained in (3) is washed with a large amount of deionized water, filtered, and dried to obtain nitrogen-sulfur double-doped graphene, which is ground into powder and used as a lithium-ion battery negative electrode material.

Embodiment 3

[0048](1) 0.2g graphene oxide is ultrasonically dispersed in deionized water at room temperature, and 10g potassium thiocyanate is dissolved in deionized water;

[0049] (2) Add potassium thiocyanate solution to the dispersion of graphene oxide, and stir the mixed solution at room temperature for 30 minutes, mix well and then dry at 120°C to obtain a composite of graphene oxide and potassium thiocyanate thing;

[0050] (3) Transfer the compound obtained in (2) to a tube furnace filled with inert gas, heat it to 300°C at a heating rate of 10°C / min, and hold the temperature for 12h to obtain the product, which is cooled to Take out after room temperature;

[0051] The reactant obtained in (3) is washed with a large amount of deionized water, filtered, and dried to obtain nitrogen-sulfur double-doped graphene, which is ground into powder and used as a lithium-ion battery negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com