Composite gel polymer electrolyte based on porous carbon material with ultrahigh specific surface area and preparation method and application thereof

A technology of ultra-high specific surface area and porous carbon materials, which is applied in the direction of composite electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problems of low porosity, small amount of liquid electrolyte, and inability to achieve high conductivity, etc. Ionic conductivity and the effect of improving the liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

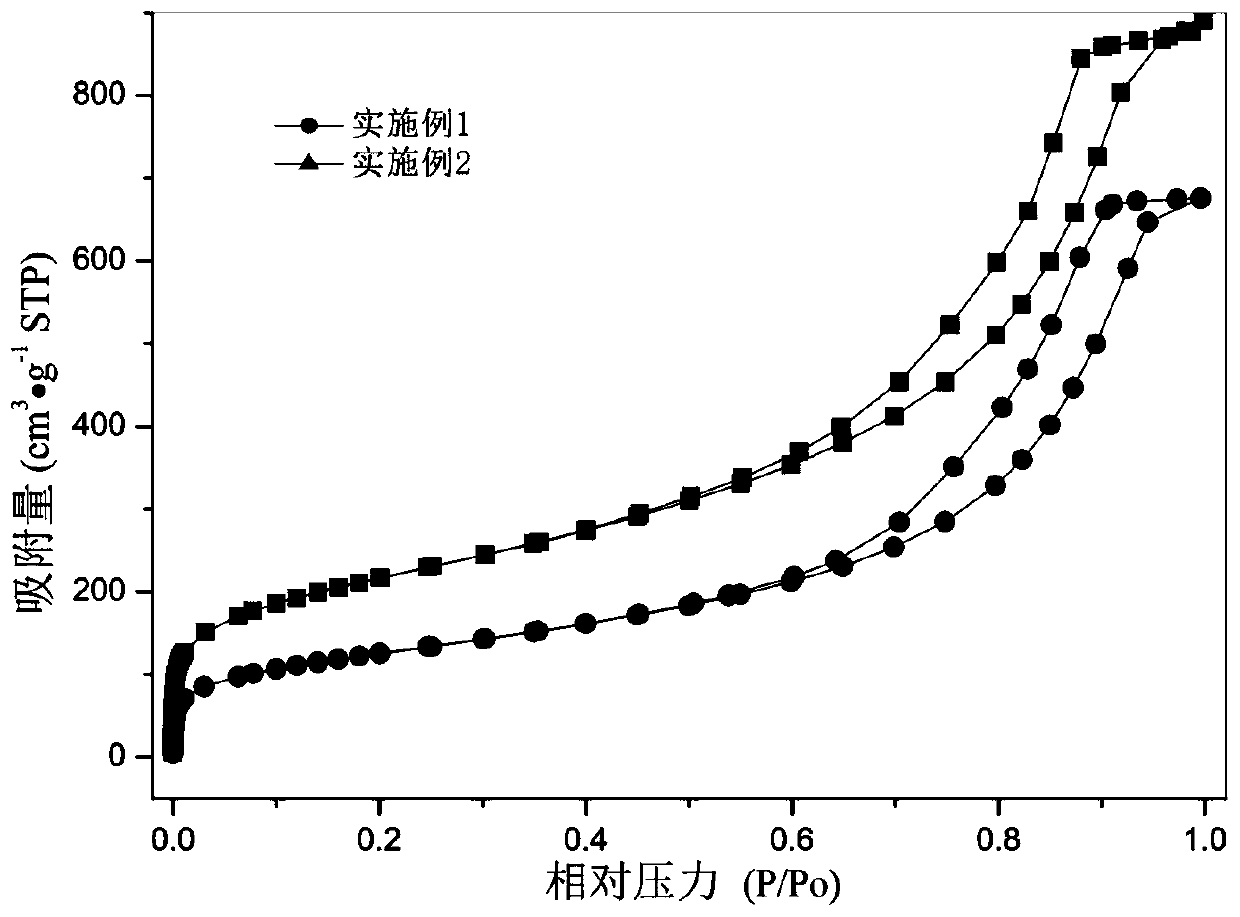

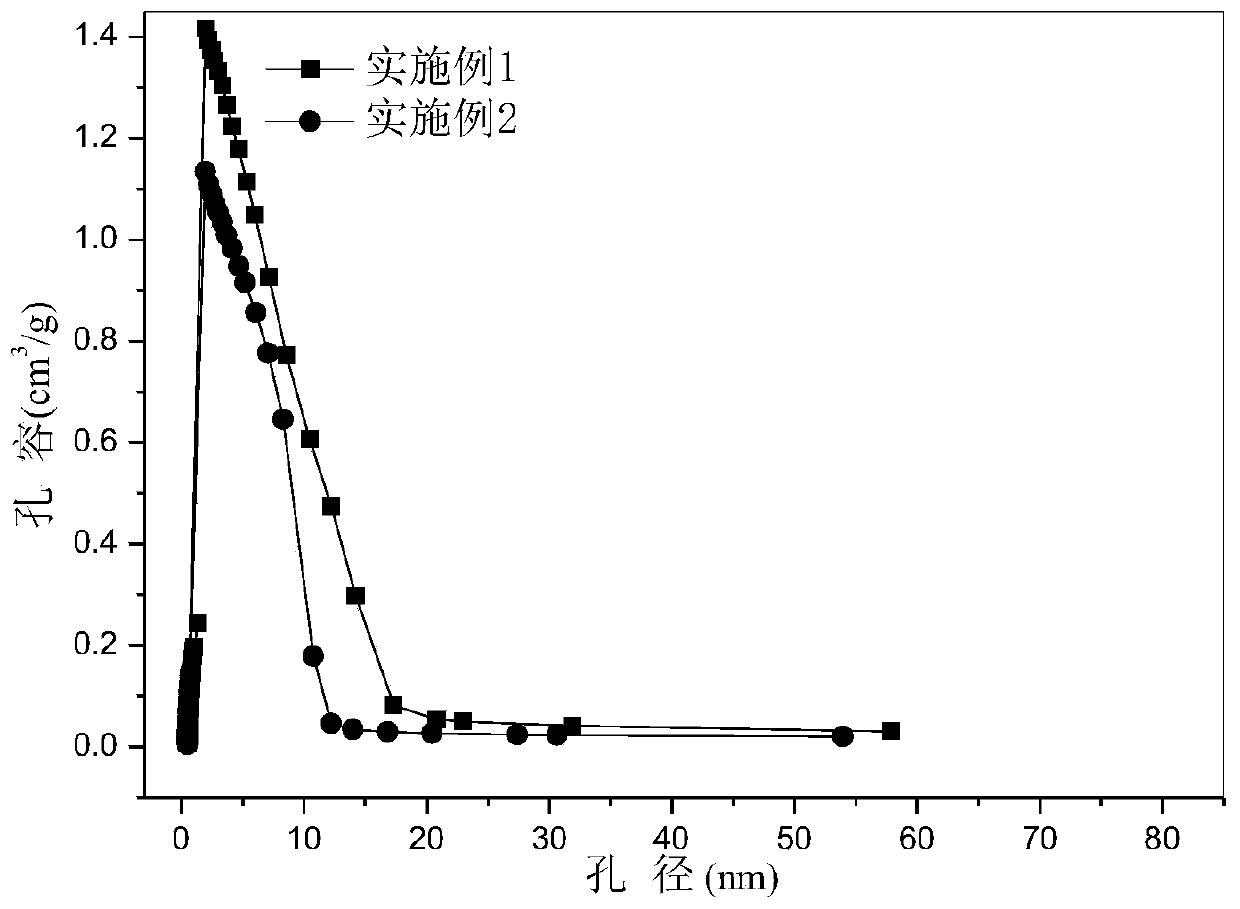

Embodiment 1

[0052] (1) Mix 100 ml of 0.5 mol / L sodium citrate ethanol aqueous solution and 100 ml of 0.3 mol / L cobalt nitrate ethanol aqueous solution, wherein the volume ratio of ethanol and water is 1:1, and then add 50 ml of 0.2 mol / L aqueous solution of potassium iron hydride, stirred evenly, put the mixed solution into the reaction kettle, sealed it, and reacted it under 100°C for 12 hours. After the reaction was completed, the temperature was naturally lowered, washed with deionized water for three times, and air-dried at 100°C to Constant weight to obtain a purple solid powder.

[0053] (2) After calcining the purple solid powder in a muffle furnace at a high temperature of 700° C. for 6 hours, a black porous cobalt oxide-iron-carbon composite electrode material was obtained.

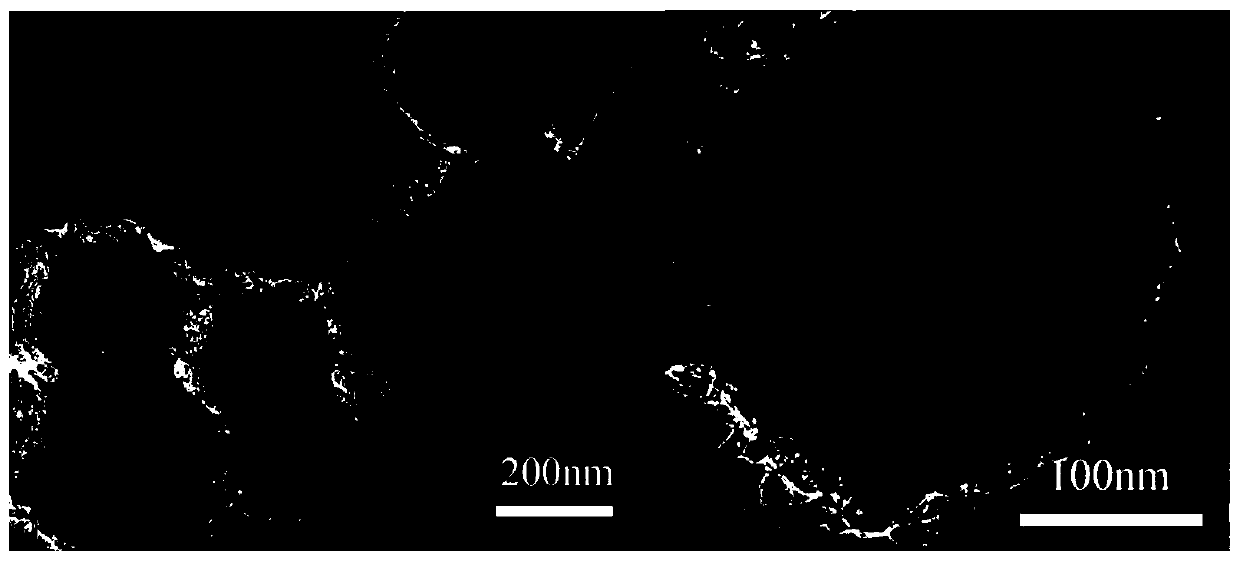

[0054] (3) Soak the black porous cobalt-iron-carbon composite electrode material in 2mol / L aqueous hydrochloric acid solution for 24 hours, then wash with deionized water, filter, and dry at 100°C for 12 ho...

Embodiment 2

[0057] (1) Mix 100 ml of 0.5 mol / L sodium citrate ethanol solution and 100 ml of 0.5 mol / L cobalt nitrate ethanol solution, wherein the volume ratio of ethanol and water is 1:1, and then add 50 ml of 0.1 mol dropwise / L aqueous solution of potassium iron hydride, stir evenly, put the mixed solution into the reaction kettle, seal it, and react it with water heat at 100°C for 10 hours. Constant weight to obtain a purple solid powder.

[0058] (2) After calcining the purple solid powder in a muffle furnace at a high temperature of 600° C. for 5 hours, a black porous cobalt oxide-iron-carbon composite electrode material was obtained.

[0059] (3) Soak the black porous structure cobalt-iron-carbon composite electrode material in 1mol / L aqueous hydrochloric acid solution for 24 hours, then wash with deionized water, filter, and dry at 100°C for 12 hours to obtain a black porous structure carbon material.

[0060] (4) Dissolve the black porous structure carbon material and polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com