A kind of polyoxometalate composite particle electrode and its preparation method and application

A polyoxometalate and composite particle technology, which is applied to a polyoxometalate composite particle electrode and the field of preparation and application thereof, can solve the problems of low redox ability, poor electrocatalytic effect, short electrode life, etc. The method is simple and easy to implement, has strong adsorption performance, and improves the effect of surface-to-body ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

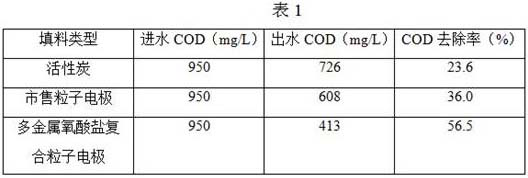

Examples

Embodiment 1

[0024] Method for preparing a multi-metal oxide composite particle electrode, comprising the steps of:

[0025] 1) The titanate is dissolved in the ultrapure water of the titanate at 50 ° C, pH = 4, and a titanium sol solution having a concentration of 0.5 mol / L is formulated;

[0026] 2) CTAb (cetyltrimethylactyl bromide) is a structural guide, the structural guiding agent is dissolved in ultra-pure water, and a CTAB solution having a concentration of 2.5 mol / L is formulated;

[0027] 3) At the 200r / min stirring speed, step 1) The obtained titanium sol solution was slowly added dropwise to the same volume of step 2) The resulting CTAB solution was stirred at 55 ° C, and the reaction was stirred at 55 ° C for 8 h. The suspension of the titanium dioxide molecular sieve precursor, centrifugal separation, the resulting solid was washed with ultrapure water to obtain a mesh titanium dioxide molecular sieve pre-mobody, and it was placed in a 95 ° C oven drying.

[0028] 4) Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com