Block polymer containing perfluoropolyether structure

A technology of block polymer and perfluoropolyether, applied in the field of organic polymer compounds, can solve problems such as no block polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

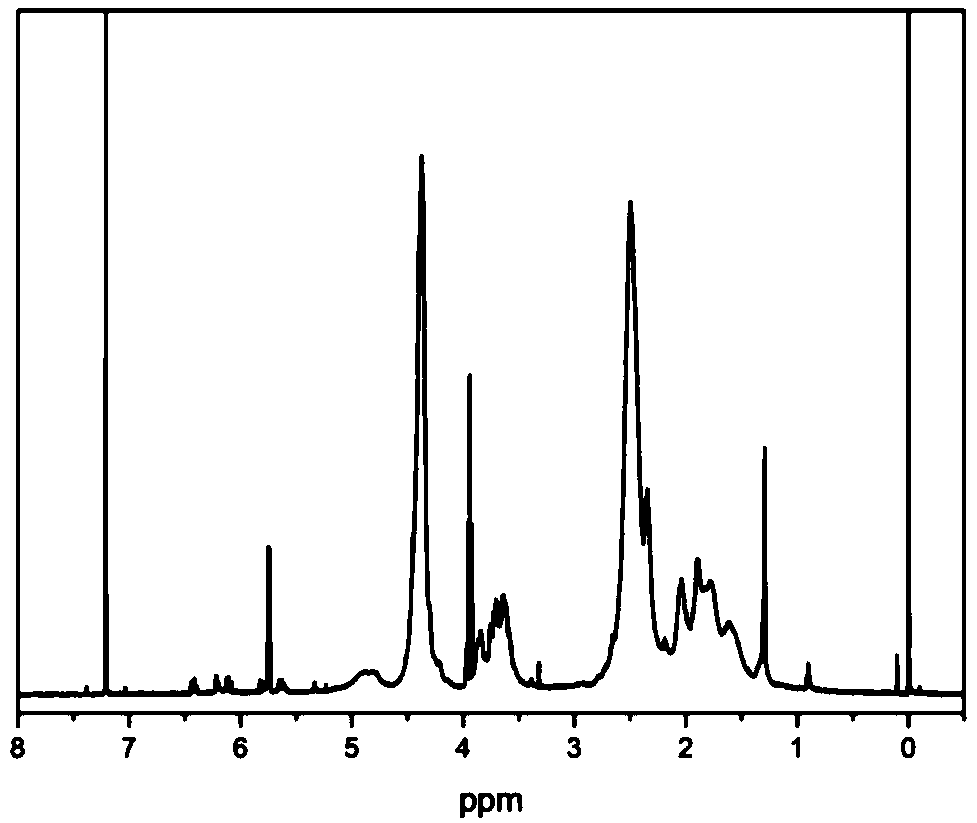

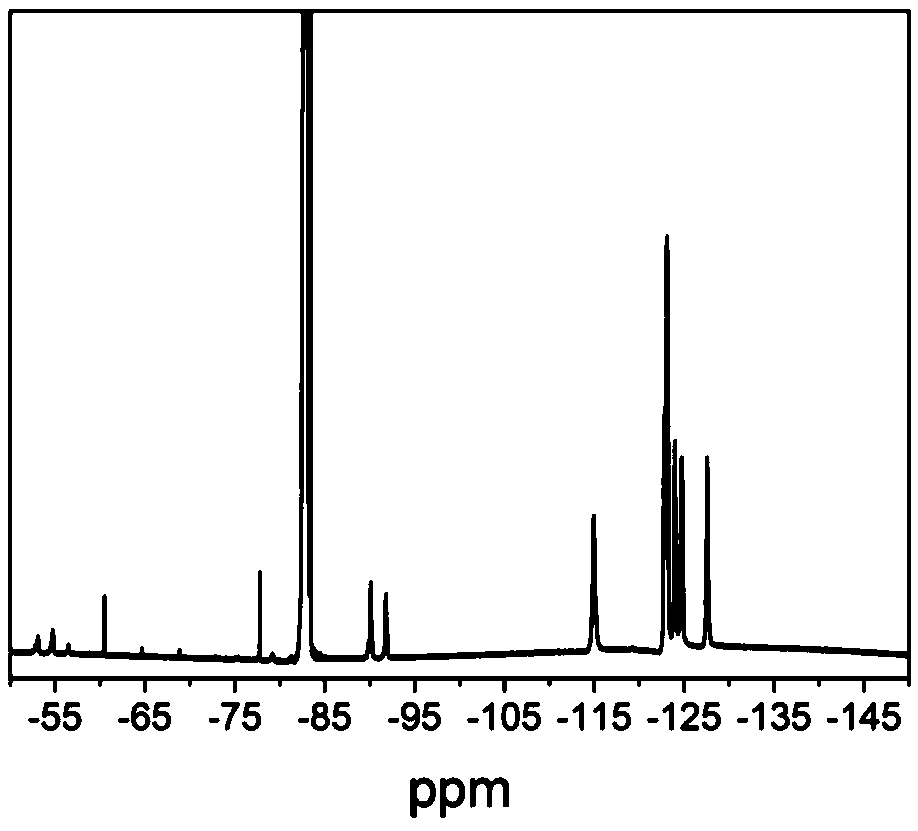

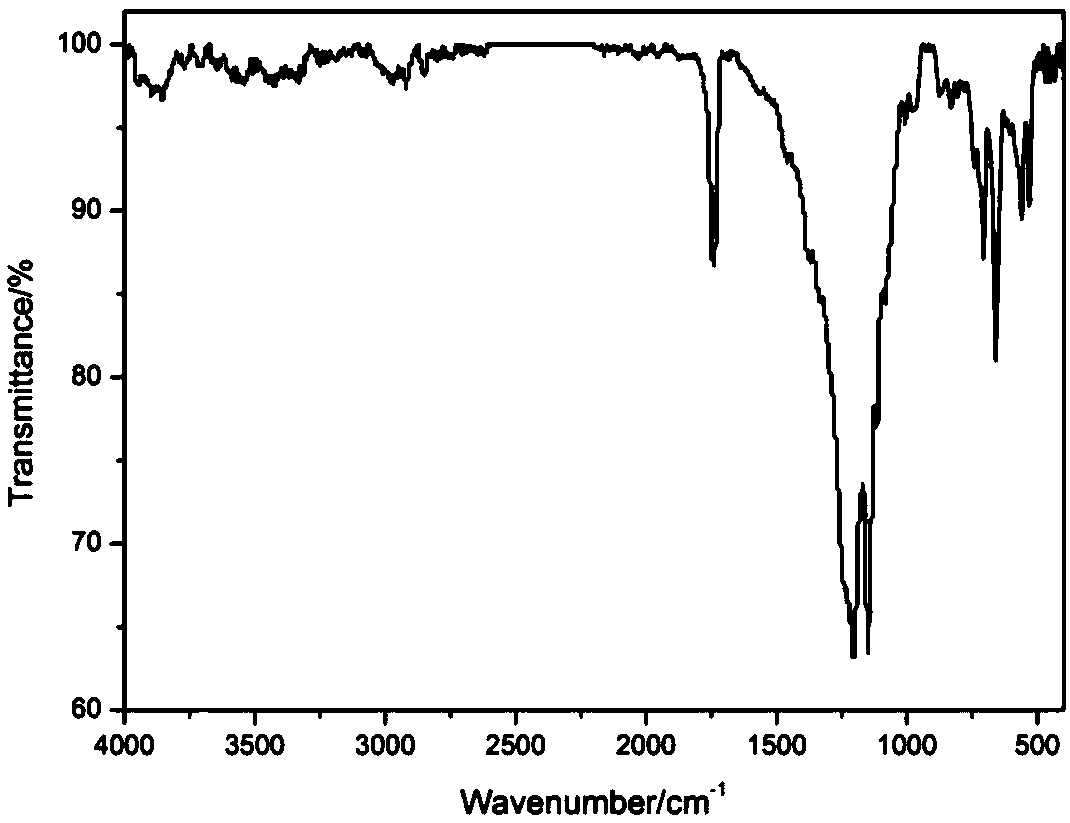

[0074] Vacuumize a 100 ml Schlenk reaction bottle with a branched mouth equipped with magnets, bake the bottle with an electric heat gun for 3 minutes under vacuum, cool to room temperature (about 25°C), replace it with nitrogen three times, and finally fill the bottle with 0.1MPa nitrogen. The reaction was placed in a constant temperature magnetic water bath with a set polymerization temperature (20°C). Add about 0.4 g of potassium hydride stored in mineral oil into the bottle, wash off the mineral oil with 5 mL of dry tetrahydrofuran each time, for a total of three times, then drain the solvent, and accurately weigh the mass of potassium hydride to obtain 2.95 mmol (0.1183 g) of dried potassium hydride. Add bishydroxyl-terminated Z-type perfluoropolyether (PFPE) into the bottle —R a —, —R a ’—both are -CH 2 CH 2 O-structure, x=8, y=7) 1.5 g, reacted for 3 hours. Add 10 mL of 3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyl acrylate into the bottle, bulk poly...

Embodiment 2

[0078] The polymerization conditions are the same as in Example 1, except that the polymerization temperature is adjusted from 20°C to 55°C, potassium hydride (2.95mmol) is changed to dimethyl sulfoxide-potassium complex (2.52mmol), and double hydroxyl end-capped Z-type PFPE1. 5g is changed to monohydroxyl-terminated K-type PFPE ( R f — for CF 3 CF 2 CF 2 -, w=5) 0.95g, the polymerization was changed from bulk polymerization to solution polymerization, using 10mL of tetrahydrofuran / methyl perfluorobutyl ether mixture (volume ratio 1:9), and the polymerization monomer was from 3,3,4,4 ,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyl acrylate (10mL) was changed to 2,2,2-trifluoroethylmethyl Acrylate (5 mL). 3.65 g of polymer was obtained with a conversion rate of 53%.

[0079] After testing, the obtained polymer is Its n value is 6 and its number average molecular weight is 2000.

Embodiment 3

[0081] The polymerization conditions are the same as in Example 1, only the polymerization temperature is adjusted from 20°C to 40°C, potassium hydride (2.95mmol) is changed to dimethyl sulfoxide-sodium complex (2.19mmol), and double hydroxyl end-capped Z-type PFPE1. 5g is changed to monohydroxyl-terminated K-type PFPE ( R f — for CF 3 CF 2 CF 2 -, w=13) 4.80g, the polymerization is changed from bulk polymerization to solution polymerization, using 20mL of ethyl perfluorobutyl ether, and the polymerization monomers are from 3,3,4,4,5,5,6,6,7, 7,8,8,9,9,10,10,10-heptadecafluorodecyl acrylate (10mL) was changed to 3,3,4,4,5,5,6,6,7,7,8, 8,8-Tridecafluorooctyl methacrylate (8 mL). 6.65 g of polymer was obtained with a conversion rate of 41%.

[0082] After testing, the obtained polymer is Its n value is 5 and its number average molecular weight is 4000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com