Preparation method of Prussian blue-doped oxygen reducing cathode film

A Prussian blue and cathode film technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of high loss of oxygen reduction activation, and achieve the effects of improving oxygen reduction catalytic efficiency, simplifying the preparation process, and reducing polarization internal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

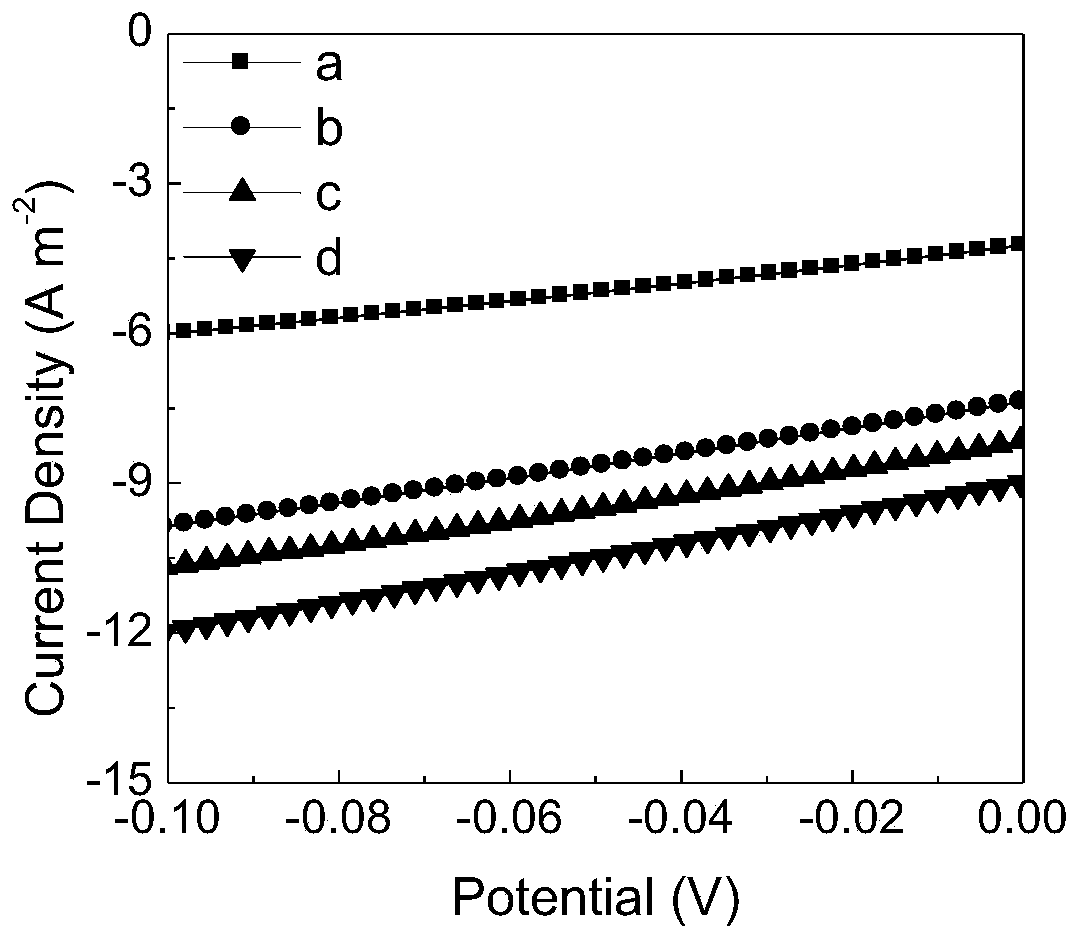

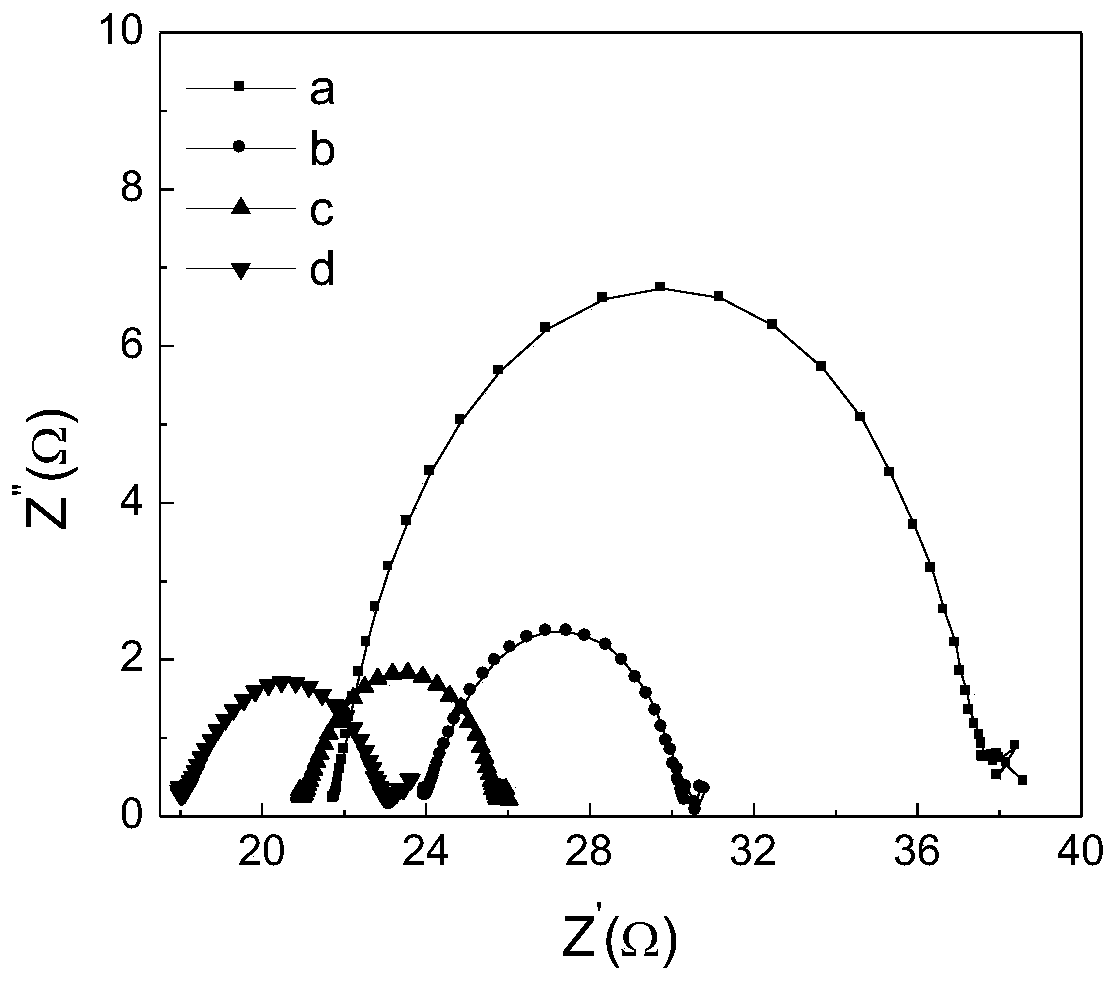

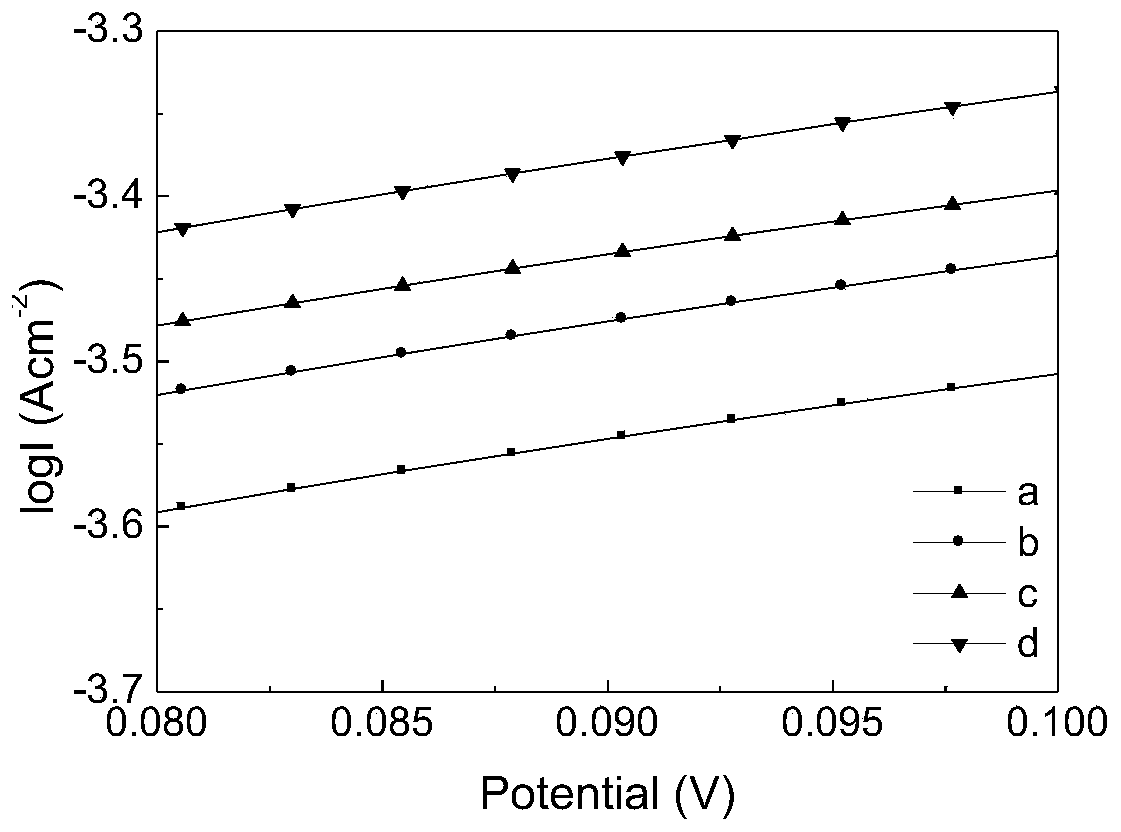

[0024] This example illustrates that the present invention provides a preparation method and characterization method of an oxygen-reducing cathode film doped with Prussian blue. Proceed as follows:

[0025] (1) Mix polyethersulfone and potassium bicarbonate at a mass ratio of 2:1 at a temperature of 30°C, dissolve in N,N-dimethylacetamide solution, wrap it in tin foil, and stir for 5 hours in the dark, and Stand still for 6 hours to obtain a homogeneous solution free of air bubbles, and the mass ratio of polyethersulfone to N,N-dimethylacetamide is 1:10. Mix polypyrrole, polyaniline and Prussian blue according to the mass ratio of 8:1:1, mix the mixed material and the homogeneous solution that has been debubbled according to the mass ratio of 0.3g:1mL, mix and ultrasonicate for 30min to make a conductive film liquid;

[0026] (2) According to the step (1) the polypyrrole loading in the conductive film solution is 25 mg cm -2 , spread the conductive film solution prepared in ...

Embodiment 2

[0034] This example illustrates that the present invention provides a preparation method and characterization method of an oxygen-reducing cathode film doped with Prussian blue. Proceed as follows:

[0035](1) Mix polyvinyl chloride and polyvinylpyrrolidone at a mass ratio of 2:1.2 at a temperature of 32°C, dissolve in an organic solvent N,N-dimethylacetamide solution, wrap it in tin foil, and stir for 6 hours in the dark , and let it stand for 6.5h to obtain a homogeneous solution without air bubbles; the mass ratio of polyvinyl chloride to N,N-dimethylacetamide is 1:12. Mix polypyrrole, polyaniline and Prussian blue according to the mass ratio of 8:1:1.5, and mix the mixed material with the homogeneous solution from which bubbles have been removed according to the mass ratio of 0.35g:1mL and ultrasonically mix for 35min to make a conductive film liquid;

[0036] (2) The polypyrrole load in the conductive film solution according to step (1) is 26 mg cm -2 , spread the condu...

Embodiment 3

[0044] This embodiment illustrates that the present invention provides a preparation method and a characterization method of doped Prussian blue oxygen-reducing cathode film, and the steps of doping the Prussian blue cathode film are as follows:

[0045] (1) Mix polyvinylidene fluoride and polyethylene glycol at a mass ratio of 2:1.5 at a temperature of 35°C, dissolve in N,N-dimethylacetamide solution, wrap it in tin foil, and stir for 7 hours in the dark , and leave it to stand for 7h to obtain a homogeneous solution that removes bubbles; the mass ratio of the polyvinylidene fluoride to N, N-dimethylacetamide is 1:13; the conductive materials polypyrrole, polyaniline and Prussian blue Mix according to the mass ratio of 8:1:2, the mixed material and the homogeneous solution from which the bubbles have been removed in the medium are mixed according to the mass ratio of 0.4g:1mL and ultrasonicated for 40min to make a conductive film liquid;

[0046] (2) According to step (1) the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com