Preparation method of photocatalyst having near-infrared responsiveness and taking porous silicon dioxide fiber as carrier and photocatalyst

A technology of porous silica and photocatalyst, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve difficult separation, recovery and reuse, Inactivation, not easy to settle and other problems, to achieve the effect of uniform shell thickness, easy operation and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1 mmol of rare earth oxide RE with a chemical molar ratio of (Y:Yb:Tm=79.5:20:0.5) 2 o 3 Dissolve in concentrated hydrochloric acid, heat until the water in the solution evaporates, dissolve in deionized water to obtain a dispersion with a concentration of 0.1mmol / L. Dissolve PVP in deionized water to obtain a dispersion with a concentration of 0.1 mmol / L, add it dropwise to the above solution, and keep stirring for 30 min until a white precipitate is formed. Then, an aqueous solution dispersed with 4 mmol NaF was added dropwise, and stirring was continued for 1 h. Move the reaction precursor solution into a 40ml reaction kettle, raise the temperature to 180°C, and react for 12 hours, then centrifuge, wash, and dry the obtained product to obtain a white powder sample.

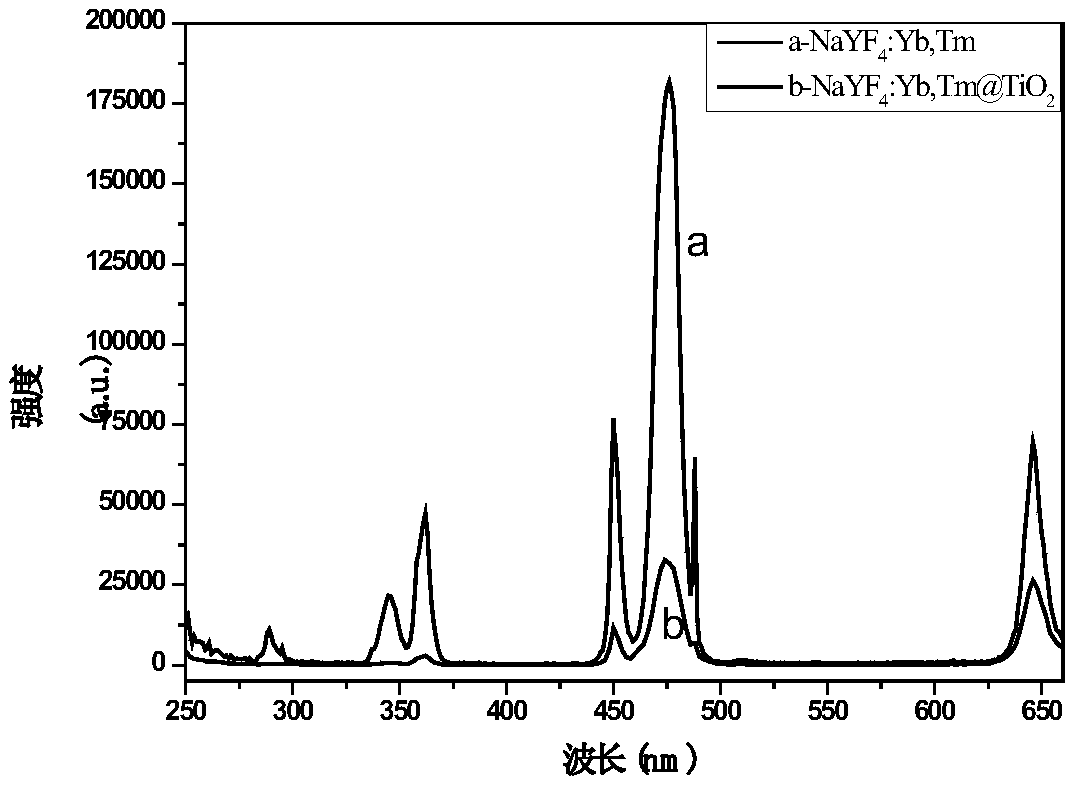

[0038] Take 50mg of prepared NaYF 4 : Yb, Tm powder ultrasonically dispersed in 10ml of absolute ethanol. Then, weigh 0.086g of butyl titanate, 0.2g of PVP, 1ml of water, and 10ml of absolute ethanol, ...

Embodiment 2

[0041] 1 mmol of rare earth oxide RE with a chemical molar ratio of (Y:Yb:Tm=79.5:20:0.5) 2 o 3 Dissolve in concentrated hydrochloric acid, heat until the water in the solution evaporates, dissolve in deionized water to obtain a dispersion with a concentration of 0.1mmol / L. Dissolve PVP in deionized water to obtain a dispersion with a concentration of 0.1 mmol / L, add it dropwise to the above solution, and keep stirring for 30 min until a white precipitate is formed. Then, an aqueous solution dispersed with 4 mmol NaF was added dropwise, and stirring was continued for 1 h. Move the reaction precursor solution into a 40ml reaction kettle, raise the temperature to 180°C, and react for 12 hours, then centrifuge, wash, and dry the obtained product to obtain a white powder sample.

[0042] Take 50mg of prepared NaYF 4 : Yb, Tm powder ultrasonically dispersed in 10ml of absolute ethanol. Then, weigh 0.086g of butyl titanate, 0.2g of PVP, 1ml of water, and 10ml of absolute ethanol...

Embodiment 3

[0045] 1 mmol of rare earth oxide RE with a chemical molar ratio of (Y:Yb:Tm=79.5:20:0.5) 2 o 3 Dissolve in concentrated hydrochloric acid, heat until the water in the solution evaporates, dissolve in deionized water to obtain a dispersion with a concentration of 0.1mmol / L. Dissolve PVP in deionized water to obtain a dispersion with a concentration of 0.1 mmol / L, add it dropwise to the above solution, and keep stirring for 30 min until a white precipitate is formed. Then, an aqueous solution dispersed with 4 mmol NaF was added dropwise, and stirring was continued for 1 h. Move the reaction precursor solution into a 40ml reaction kettle, raise the temperature to 180°C, and react for 12 hours, then centrifuge, wash, and dry the obtained product to obtain a white powder sample.

[0046] Take 50mg of prepared NaYF 4 : Yb, Tm powder ultrasonically dispersed in 10ml of absolute ethanol. Then, weigh 0.086g of butyl titanate, 0.2g of PVP, 1ml of water, and 10ml of absolute ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com