Method for producing food-grade sodium dihydrogen phosphate by using wet-process dilute phosphoric acid

A technology of sodium dihydrogen phosphate and dilute phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve the effect of simplified process, good solubility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

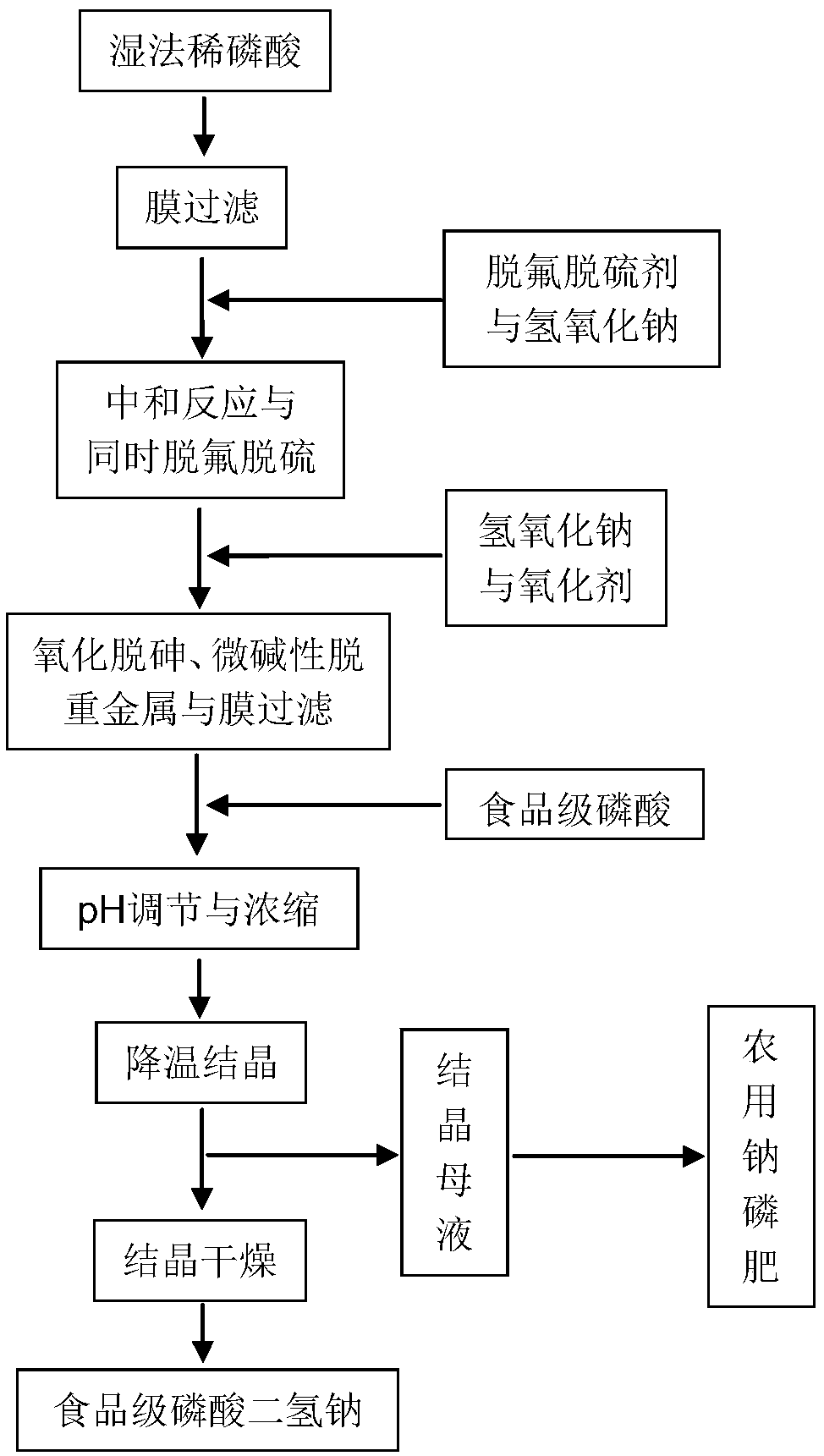

Image

Examples

Embodiment 1

[0036] A kind of method that utilizes wet process dilute phosphoric acid to manufacture food-grade sodium dihydrogen phosphate, its step is:

[0037] (1) Membrane filtration: Take the wet-process dilute phosphoric acid (aqueous solution) whose main components are 40% (mass fraction) of phosphoric acid content, 1.5% (mass fraction) of sulfate radical content and 0.5% (mass fraction) of fluoride ion content to 0-40°C, 2.29kg in an acid-resistant container, use a microporous membrane device with a membrane material of silicon carbide, a membrane pore of 0.04 μm, and a membrane module in the form of a briquette-type inner tube membrane to filter it precisely to separate pigment particles, suspended solids, and solid particles, etc. , get finely filtered wet-process dilute phosphoric acid for future use.

[0038] (2) Neutralization reaction and simultaneous defluorination and desulfurization: Take the precision-filtered wet-process dilute phosphoric acid obtained in step (1) in an ...

Embodiment 2

[0045] A kind of method that utilizes wet process dilute phosphoric acid to manufacture food-grade sodium dihydrogen phosphate, its step is:

[0046] (1) Membrane filtration: Take 11.56 kg of wet-process dilute phosphoric acid (aqueous solution) whose main components are phosphoric acid content 43% (mass fraction), sulfate radical content 1.6% (mass fraction) and fluoride ion content 0.6% (mass fraction) in an acid-resistant container , using microporous membrane equipment with membrane material of silicon carbide, membrane pores of 0.1 μm, and membrane components in the form of briquette-type inner tubular membranes to precisely filter it, separate pigment particles, suspended solids and solid particles, etc., and obtain precision-filtered wet French dilute phosphoric acid for use.

[0047] (2) Neutralization reaction and simultaneous defluorination and desulfurization: Take the precision-filtered wet-process dilute phosphoric acid obtained in step (1) in an acid-resistant co...

Embodiment 3

[0054] A kind of method that utilizes wet process dilute phosphoric acid to manufacture food-grade sodium dihydrogen phosphate, its step is:

[0055] (1) Membrane filtration: Take 5.75 kg of wet-process dilute phosphoric acid (aqueous solution) whose main components are phosphoric acid content 37% (mass fraction), sulfate radical content 1.4% (mass fraction) and fluoride ion content 0.4% (mass fraction) in an acid-resistant container , using microporous membrane equipment with membrane material of silicon carbide, membrane pores of 0.04 μm, and membrane components in the form of briquette-type inner tubular membranes to precisely filter it, separate pigment particles, suspended solids and solid particles, etc., and obtain precision-filtered wet French dilute phosphoric acid for use.

[0056] (2) Neutralization reaction and simultaneous defluorination and desulfurization: Take the precision-filtered wet-process dilute phosphoric acid obtained in step (1) in an acid-resistant co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com