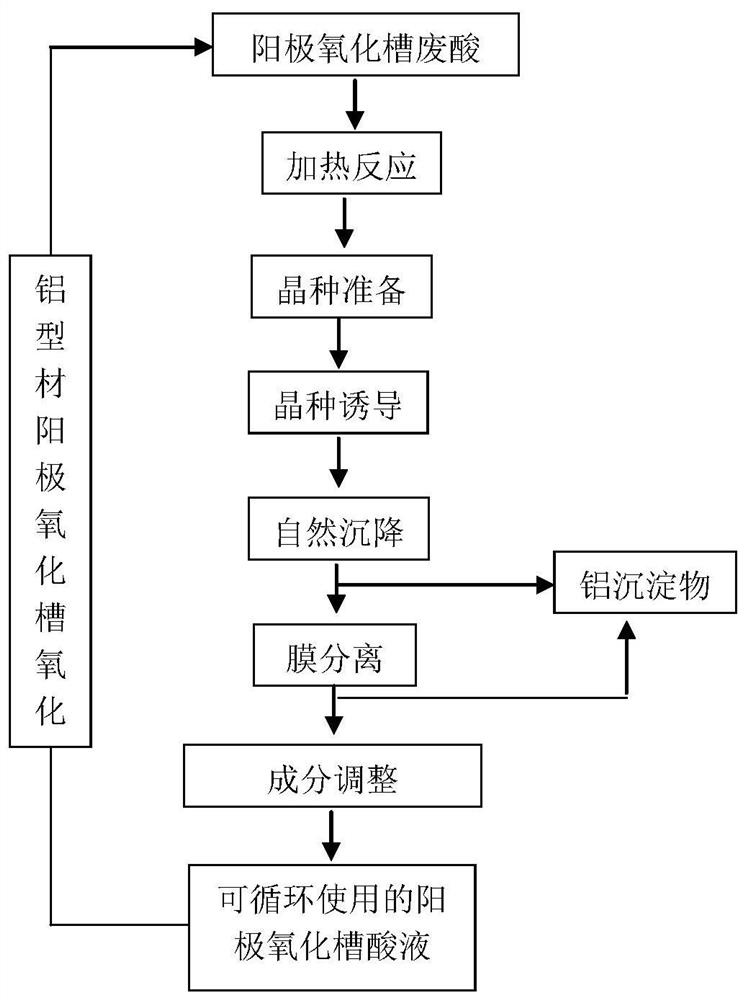

A treatment method for recycling waste acid in anodic oxidation tanks of aluminum profiles

An anodic oxidation tank and treatment method technology, applied in the field of aluminum profile processing, can solve the problems of waste pollution, difficult treatment, high cost, etc., and achieve the effects of avoiding strong environmental pollution, high raw material utilization rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A treatment method for recycling spent acid in anodic oxidation tanks of aluminum profiles, the steps of which are:

[0040] (1) Heating reaction: The main components are 19% (mass fraction) of sulfuric acid, 1.8% (mass fraction) of aluminum ions, 1.7% (mass fraction) of LY-920 wide temperature oxidant for aluminum profile anodizing and 77.5% (mass fraction) of water Put 500 grams of waste acid in the anodizing tank of aluminum profiles in a grinding-mouth Erlenmeyer flask, add 1.5% dodecylbenzenesulfonic acid by mass under the stirring condition of 100 rpm, turn on the cold water reflux, and heat the mixture to 85 ℃ and maintained at 85 ℃, continue to heat and stir for 8 hours to react the dodecylbenzenesulfonic acid with aluminum ions to form the corresponding aluminum dodecylbenzenesulfonate, and obtain the reaction solution for future use.

[0041] (2) Seed crystal preparation: take solid analytically pure aluminum dodecylbenzenesulfonate, pulverize it with a stainl...

Embodiment 2

[0048] A treatment method for recycling spent acid in anodic oxidation tanks of aluminum profiles, the steps of which are:

[0049] (1) Heating reaction: The main components are 16% (mass fraction) of sulfuric acid, 2.1% (mass fraction) of aluminum ions, 1.3% (mass fraction) of LY-920 wide temperature oxidant for aluminum profile anodizing and 80.6% (mass fraction) of water Put 650 grams of waste acid in the anodizing tank of aluminum profiles into a ground-mouth Erlenmeyer flask, add 2.5% phytic acid by mass under the stirring condition of 130rpm, turn on the cold water reflux, heat the mixture to 90°C and maintain it at 90°C , continue to heat and stir for 9 hours to react the phytic acid and aluminum ions to generate the corresponding aluminum phytate, and obtain the reaction solution for later use.

[0050] ⑵Preparation of crystal seeds: take solid analytically pure aluminum phytate, pulverize it with a stainless steel pulverizer, and pass through a 160-mesh standard sieve...

Embodiment 3

[0057] A treatment method for recycling spent acid in anodic oxidation tanks of aluminum profiles, the steps of which are:

[0058] (1) Heating reaction: The main components are 20.5% (mass fraction) of sulfuric acid, 2.4% (mass fraction) of aluminum ions, 0.7% (mass fraction) of LY-920 wide temperature oxidant for anodizing aluminum profiles and 76.4% (mass fraction) of water Put 832 grams of waste acid in the anodizing tank of aluminum profiles in a ground-mouth Erlenmeyer flask, add oxalic acid with a mass fraction of 3.0% under the stirring condition of a stirring speed of 150 rpm, turn on the cold water reflux, heat the mixture to 80°C and maintain it at 80°C , continue heating and stirring for 12 hours to react the oxalic acid and aluminum ions to generate the corresponding aluminum oxalate, and obtain the reaction solution for later use.

[0059] (2) Preparation of seed crystals: take solid analytically pure aluminum oxalate, pulverize it with a stainless steel pulveriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com