Fabrication method of fluorescent sensitive film for optical fiber explosive sensor, optical fiber explosive sensor and explosive vapor detection system

A technology for sensitive thin films and explosives, applied in the directions of fluorescence/phosphorescence, light guides doped with fluorescent agents, cladding fibers, etc. It can solve the problems of low saturated vapor pressure and the inability of sensors to achieve fast film formation and improved response. Speed and sensitivity, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

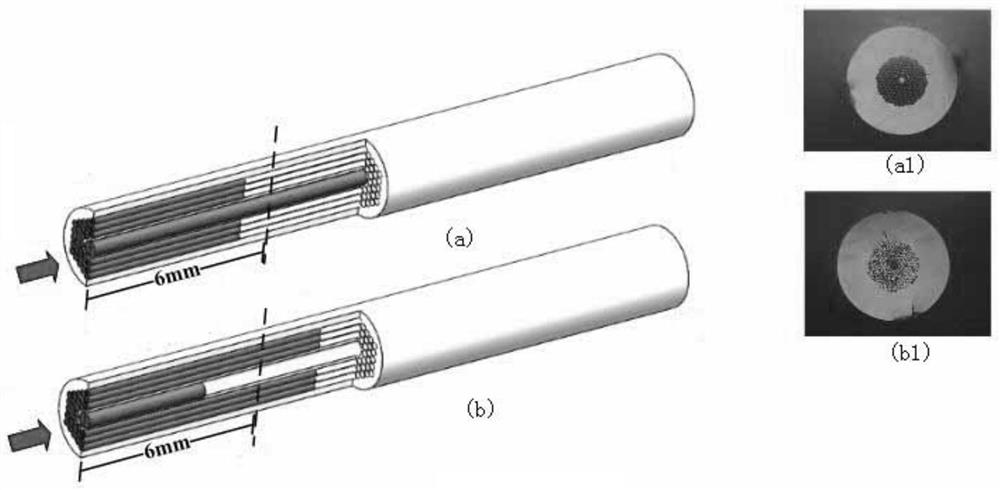

[0040] In this embodiment, the method for preparing the fluorescent sensitive film of the optical fiber explosive sensor comprises the following steps:

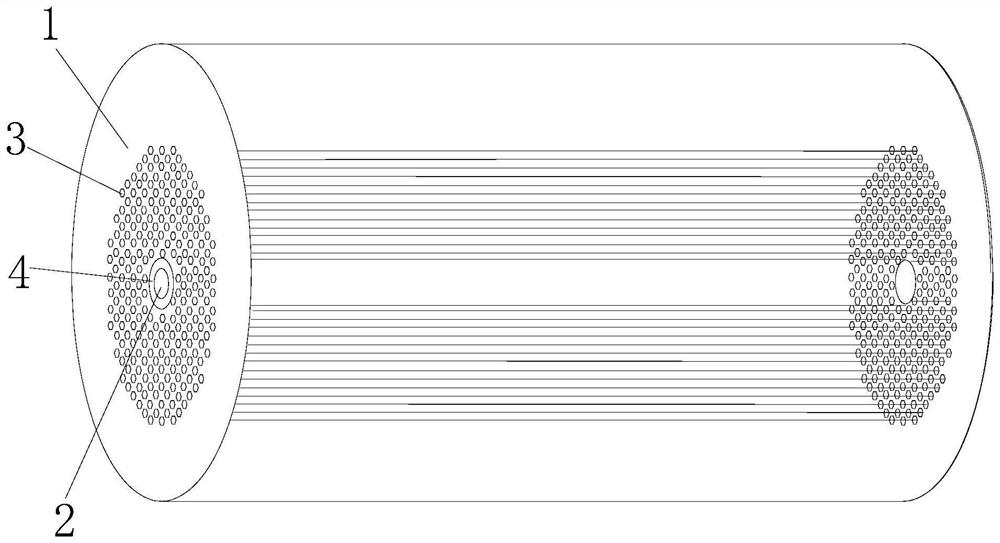

[0041] 1) Seal the cladding air holes of the hollow-core photonic crystal fiber (HC-PCF) with UV-curable glue; the structure of the hollow-core photonic crystal fiber is as follows figure 2 As shown, it includes silica glass cladding 1 , core air holes 2 and cladding air holes 3 .

[0042] According to the knowledge of fluid mechanics, when the solution is filled by the capillary action of the hollow core photonic crystal fiber (HC-PCF) air hole, the filling speed can be obtained according to the following related formula:

[0043]

[0044] Among them, υ is the average speed of UV curing glue in the HC-PCF air hole, r is the radius of the HC-PCF air hole, Δp is the air pressure difference at both ends of the HC-PCF air hole, l is the distance length filled by the UV curing glue, μ is the viscosity of the UV-curable adhes...

example 1

[0076] Example 1: The thickness of the fluorescent vapor sensitive film containing enphenyltetraphenylethylene coated on the inner wall of the core of the hollow-core photonic crystal fiber is 50 nm. Taking trinitrotoluene, 2-4 dinitrotoluene, 2-6 dinitrotoluene, p-nitrotoluene, 1, 3, 5 trinitrotoluene and the vapor of water at saturated vapor pressure as the research objects, Make each research object interact with the fluorescent sensitive film on the inner wall of the fiber core air hole respectively.

[0077] In the experiment, the known saturated vapor pressure concentration is 0ppb (water), 10ppb (trinitrotoluene), 20ppb (1,3,5-trinitrotoluene), 400ppb (2,4 dinitrotoluene), 650ppb ( The explosive vapors of p-nitrotoluene) and 900ppb (2,6-dinitrotoluene) were detected respectively, and the corresponding fluorescence intensity changes ΔI were measured as 0, 950 (a.u), 1740 (a.u), 9784 (a.u ), 12700(a.u), 15860(a.u), the obtained linear regression equation is: ΔI=17.504c+1...

example 2

[0079] Example 2: The thickness of the fluorescent film of explosive vapor containing enphenyltetraphenylethylene coated on the inner wall of the core of the hollow-core photonic crystal fiber is 100 nm. The known saturated vapor pressure concentration is 0ppb (water), 10ppb (trinitrotoluene), 20ppb (1,3,5-trinitrotoluene), 400ppb (2,4-dinitrotoluene), 650ppb (p-nitrotoluene) Toluene) and 900ppb (2,6 dinitrotoluene) explosive vapors were detected respectively. The corresponding fluorescence intensity change ΔI is 0, 1020(a.u), 1966(a.u), 10040(a.u), 13680(a.u), 17840(a.u), then the linear regression equation is: ΔI=19.353c+1037.9, correlation coefficient R 2 =0.9879, that is, k and b in the linear regression equation are 19.353 and 1037.9 respectively.

[0080] When the explosive vapor to be measured is in contact with the sensitive film on the inner surface of the air hole of the hollow-core photonic crystal fiber core, the average change in fluorescence intensity ΔI is 678...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com