Thin-layer boron nitride nano-sheet preparation method

A technology of boron nitride sheets and boron nitride, which is applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of low output, difficulty in obtaining boron nitride nano-powders, and large energy loss, etc., and achieves a compensation technology Defects, effects of bulk preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Further, a method for preparing thin-layer boron nitride nanosheets provided by an embodiment of the present invention includes:

[0019] The boron nitride raw material is mixed with the intercalation agent, placed in a sealed environment, and heated for intercalation reaction, so that the intercalation agent molecules are partially or completely inserted into the layered structure of boron nitride to form intercalated boron nitride;

[0020] Vaporize or decompose the intercalant molecules in the intercalated boron nitride to generate gases, or react the intercalant molecules in the intercalated boron nitride with selected chemical substances to generate gases, so that the boron nitride sheets are cleaved and peeled off , to obtain thin boron nitride nanosheets.

[0021] Further, the boron nitride raw material includes any one of flake boron nitride, boron nitride powder and boron nitride bulk material, but is not limited thereto.

[0022] Further, the intercalation ag...

Embodiment 1

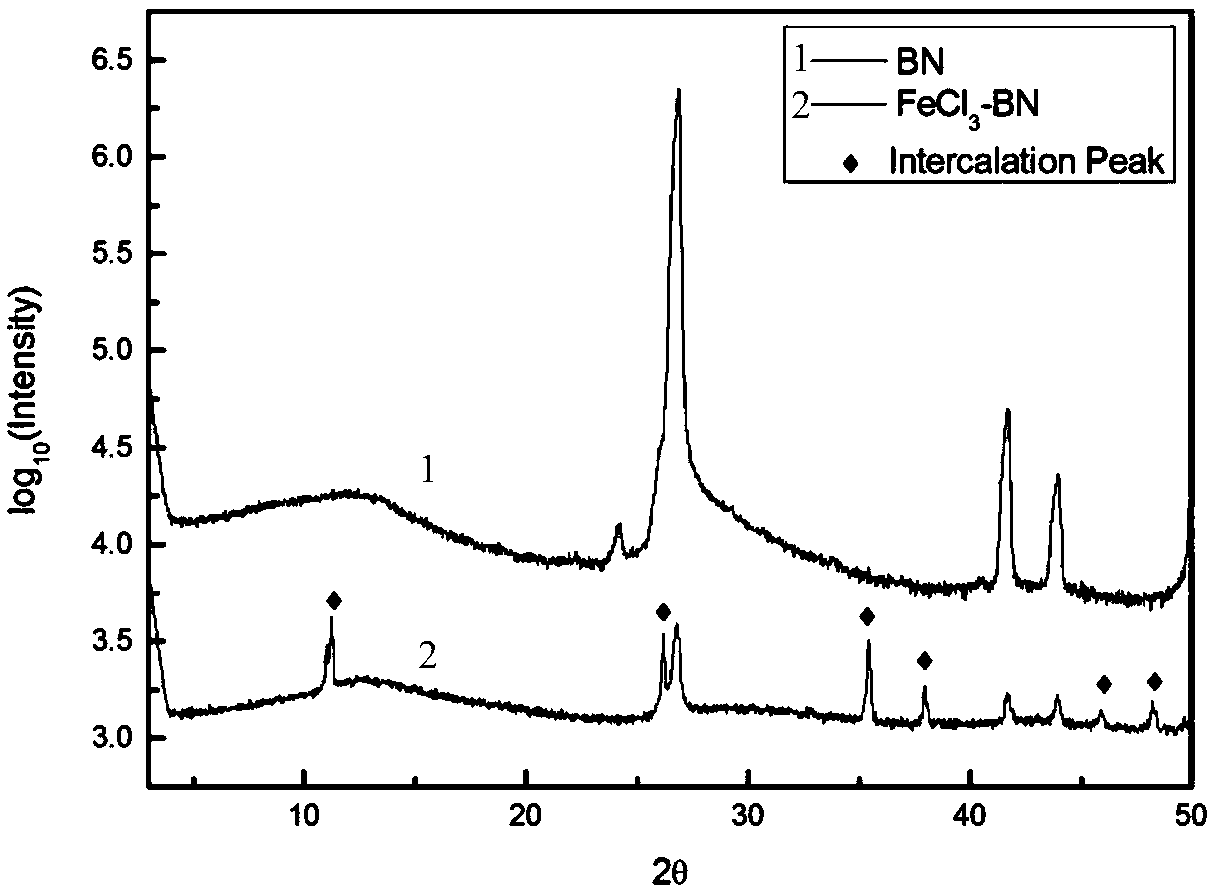

[0034] Embodiment 1: the preparation method of this thin-layer boron nitride nanosheet comprises: adopt anhydrous ferric chloride as intercalation agent, during reaction, 3g anhydrous ferric chloride powder and 1g boron nitride powder (particle size about 10 -20 microns), respectively placed in two sections of the intercalation chamber, after the intercalation chamber is sealed, the pressure is at normal pressure, placed in a high-temperature oven, the reaction temperature is adjusted to 300 ° C, and the reaction time is 40 hours. After the reaction was completed, the intercalation chamber was taken out, opened and cleaned, and it was found that the original white boron nitride powder had changed to light yellow. XRD analysis was carried out on the powder after intercalation ( figure 1 ), it can be seen that boron nitride is intercalated by ferric chloride to produce a new intercalation peak, and the intercalation is 2-order intercalation. Put the intercalation in hydrogen pe...

Embodiment 2

[0035] Embodiment 2: The preparation method of this thin-layer boron nitride nanosheet comprises: using anhydrous copper chloride as intercalation agent, during reaction, 10g anhydrous copper chloride powder and 1g boron nitride (10-20 micron) The powder is fully stirred and mixed evenly, and placed in a closed quartz container, the closed quartz container is placed in a muffle furnace, the reaction temperature is adjusted to 700 ° C, and the reaction time is 60 hours. After the reaction was completed, the intercalation chamber was taken out, opened and cleaned, and it was found that the original white boron nitride powder had changed to light yellow. Wash the reactants after intercalation, dry them at 100°C, place them in a near-vacuum reaction vessel, and heat them rapidly to 1500°C, so that the copper chloride in the intercalation part is rapidly vaporized, and the boron nitride is cleaved and peeled off. , and then through pickling, ultrasonic cleaning with pure water, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com