Environmentally-friendly high-temperature-resistant special double-sided adhesive tape and preparation method thereof

A double-sided tape, high temperature resistance technology, applied in special paper, pulp beating/refining method, adhesives, etc., can solve the problem that the continuous bonding ability cannot meet the high and low temperature resistance, damage, air pollution and other problems, and achieve good application Prospect, preparation method is simple and scientific, easy to degrade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

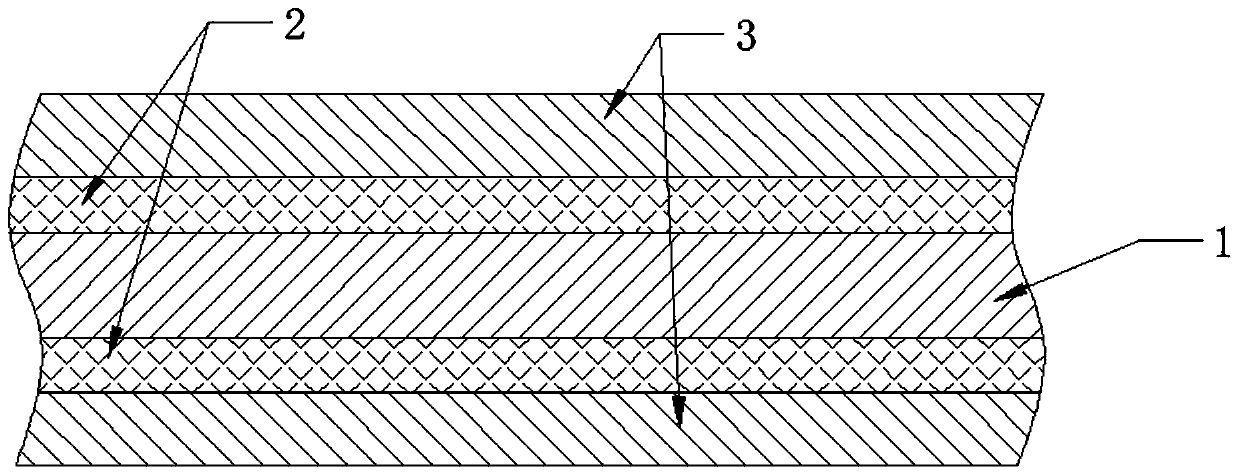

[0036] see figure 1 , the present invention provides a technical solution: an environmentally friendly high-temperature-resistant special double-sided tape, including a PP composite film base material 1, a pressure-sensitive adhesive layer 2 located on both sides of the PP composite film base material 1, and a pressure-sensitive adhesive layer located on both sides Release paper layer 3 on the outside of layer 2; the raw material formula of the pressure-sensitive adhesive layer 2 includes the following components by mass: 60 parts of monomeric isooctyl acrylate 2-EHA, 20 parts of monomeric butyl acrylate BA and modified monomer 6 parts of bulk maleimide resin, 26 parts of initiator AIBN, 60 parts of ethyl acetate solvent, 9 parts of TMPTA curing agent.

[0037] A preparation method of an environment-friendly high temperature resistant special double-sided adhesive tape, the specific steps are as follows:

[0038] S1: Put the monomer isooctyl acrylate 2-EHA, the monomer butyl ...

Embodiment 2

[0044] see figure 1, the present invention provides a technical solution: an environmentally friendly high-temperature-resistant special double-sided tape, including a PP composite film base material 1, a pressure-sensitive adhesive layer 2 located on both sides of the PP composite film base material 1, and a pressure-sensitive adhesive layer located on both sides Release paper layer 3 on the outside of layer 2; the raw material formula of the pressure-sensitive adhesive layer 2 includes the following components by mass: 75 parts of monomer isooctyl acrylate 2-EHA, 25 parts of monomer butyl acrylate BA and modified monomer 8 parts of bulk maleimide resin, 32.5 parts of initiator AIBN, 70 parts of solvent, and 11 parts of curing agent.

[0045] A preparation method of an environment-friendly high temperature resistant special double-sided adhesive tape, the specific steps are as follows:

[0046] S1: Put the monomer isooctyl acrylate 2-EHA, the monomer butyl acrylate BA and th...

Embodiment 3

[0052] see figure 1 , the present invention provides a technical solution: an environmentally friendly high-temperature-resistant special double-sided tape, including a PP composite film base material 1, a pressure-sensitive adhesive layer 2 located on both sides of the PP composite film base material 1, and a pressure-sensitive adhesive layer located on both sides Release paper layer 3 on the outside of layer 2; the raw material formula of the pressure-sensitive adhesive layer 2 includes the following components by mass: 90 parts of monomeric isooctyl acrylate 2-EHA, 30 parts of monomeric butyl acrylate BA and modified monomer 10 parts of bulk maleimide resin, 39 parts of initiator AIBN, 80 parts of ethyl acetate solvent, 13 parts of TMPTA curing agent.

[0053] A preparation method of an environment-friendly high temperature resistant special double-sided adhesive tape, the specific steps are as follows:

[0054] S1: Put the monomer isooctyl acrylate 2-EHA, the monomer buty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com