Planar capacitor with high stripping force and high dielectric constant and preparation method thereof

A capacitor and planar technology, applied in the field of planar capacitors and its preparation, can solve the problems of inability to form planar capacitor products with use value, poor adhesion of dielectric materials to metal films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

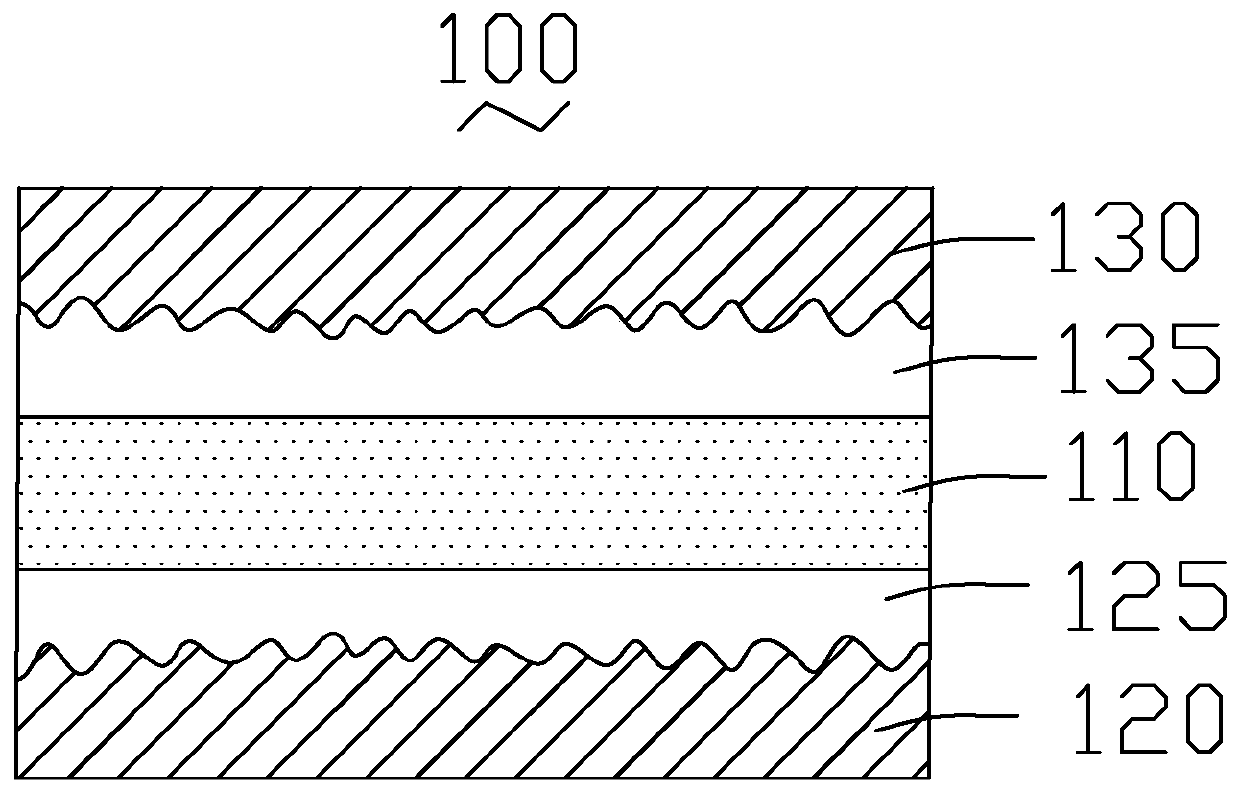

[0028] The present invention also provides a preparation method of the planar capacitor, such as Figure 2-Figure 5 Shown, this preparation method comprises the steps:

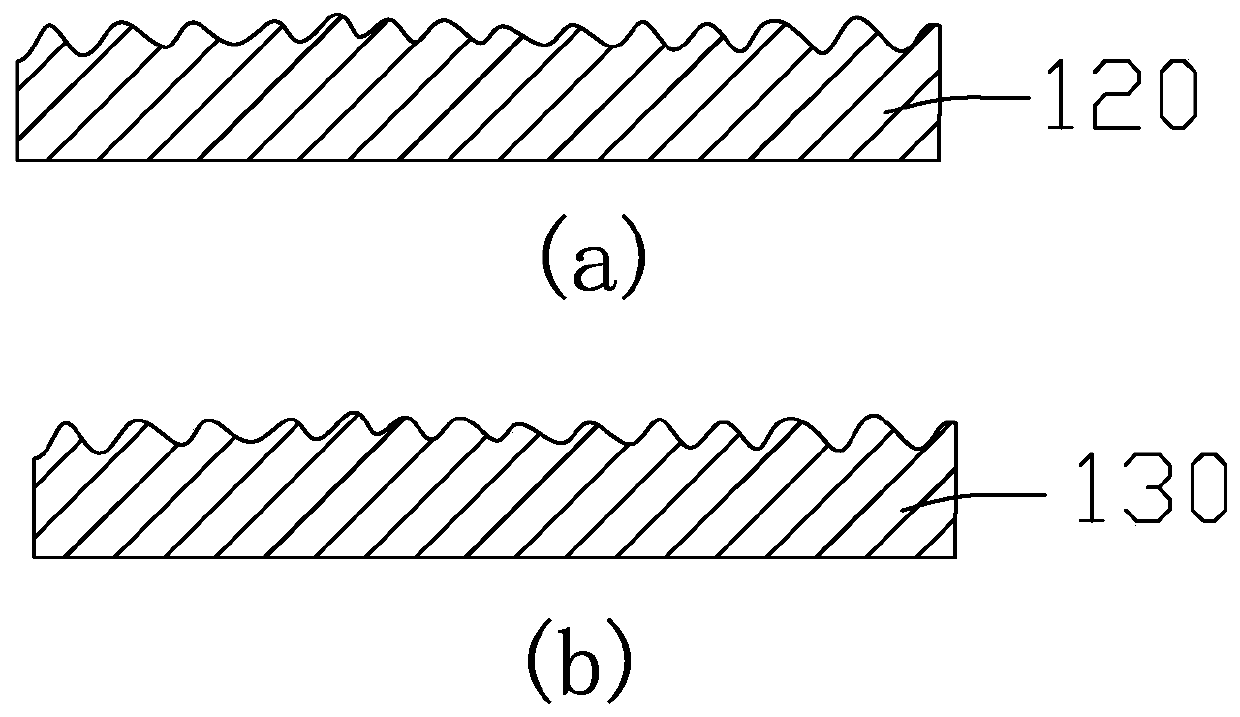

[0029] Such as figure 2 , roughening the surfaces of the first metal film 120 and the second metal film 130;

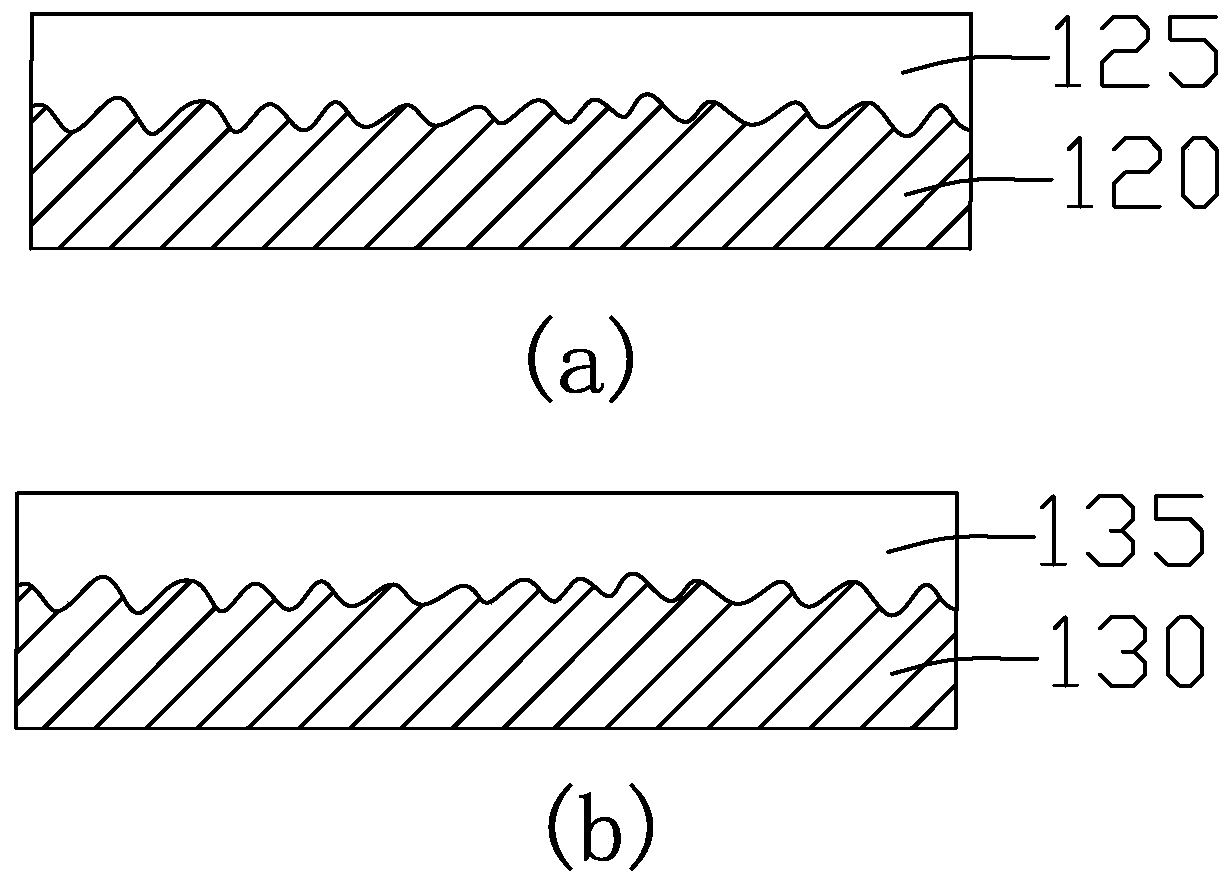

[0030] Such as image 3As shown, a first silane coupling agent layer 125 is formed on the roughened surface of the first metal film 120, and a second silane coupling agent layer 135 is formed on the roughened surface of the second metal film 130;

[0031] Such as Figure 4 As shown, the dielectric layer 110 is formed on the surface of the first silane coupling agent layer 125, and the dielectric layer 110 contains a thermosetting polymer capable of reacting with the silane coupling agent;

[0032] Such as Figure 5 As shown, the second silane coupling agent layer 135 formed on the surface of the second metal film 130 is attached to the surface of the dielectric layer 110; and

[0033] The plana...

Embodiment 1

[0055] Two pieces of copper foil with a thickness of 35 μm are provided, and the surface roughness value Ra of the copper foil is 0.5 μm by using a surface roughening process as the first metal film and the second metal film. The surface roughening treatment process includes: soaking the copper foil with PCB copper foil brown oxidation solution for 30s, then rinsing it with pure water, and drying it at 60°C to complete the roughening treatment.

[0056] Prepare a silane coupling agent solution with a concentration of 1%wt by using amino-containing silane KH550 and 95% ethanol. After mixing evenly, place and mature at room temperature for 2 to 3 hours to obtain a silane coupling agent solution for use.

[0057] Coating the silane coupling agent solution on the roughened surface of the first metal film and the second metal film respectively, and drying at 60°C for 20 minutes to obtain a layer coated with the first silane coupling agent respectively The first metal film and the s...

Embodiment 2

[0063]Two pieces of copper foil with a thickness of 25 μm are provided, and a surface roughening treatment process is used to make the surface roughness value of the copper foil Ra=0.5 μm, as the first metal film and the second metal film. The surface roughening treatment process includes: sandblasting with 1000 mesh silicon nitride for 20s, and then removing the sand on the surface to complete the roughening treatment;

[0064] Use siloxane KH570 containing methyl acrylate group and 95% ethanol to prepare a silane coupling agent solution with a concentration of 1.5% wt. After mixing evenly, place it at room temperature for aging for 2 to 3 hours to obtain a silane coupling agent solution for later use;

[0065] The silane coupling agent solution is coated on the surface of the first metal film and the roughened surface of the second metal film respectively, and then dried at 60°C for 20 minutes to obtain the surface coated with the first silane coupling agent. The first metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com