Device and method for desulfurization of coke oven flue gas

A technology for desulfurization equipment and flue gas, applied in separation methods, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of high difficulty, complicated extraction process of absorption products, waste heat of flue gas of sulfur absorption equipment not being utilized by components, etc. , to achieve the effect of mature and convenient cycle process, clever combination and easy monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

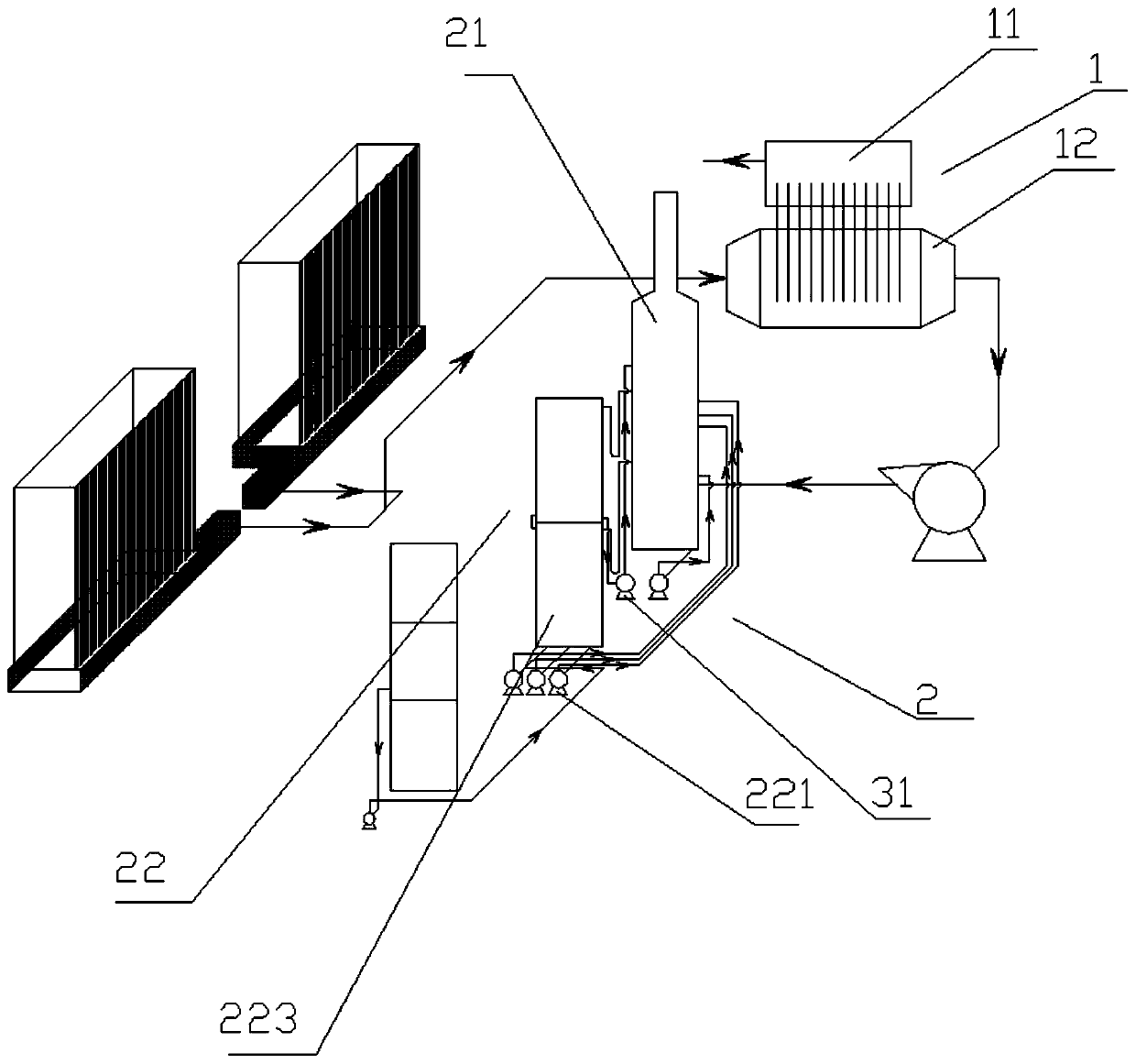

[0035] A coke oven flue gas desulfurization equipment, comprising waste heat application equipment 1 and circulation desulfurization equipment 2, the inlet of waste heat application equipment 1 is connected to the outlet of coke oven flue gas, and the outlet of waste heat application equipment 1 is connected to the inlet of circulation desulfurization equipment 2.

[0036] Waste heat application equipment includes an economizer 11 and a waste heat boiler 12; the coke oven flue gas outlet is connected to the heating section of the economizer 11 and the evaporator of the waste heat boiler 12; the boiler water of the economizer 11 is passed into the waste heat boiler 12; The flue gas outlets of coal heater 11 and waste heat boiler 12 are connected with desulfurization equipment 2 .

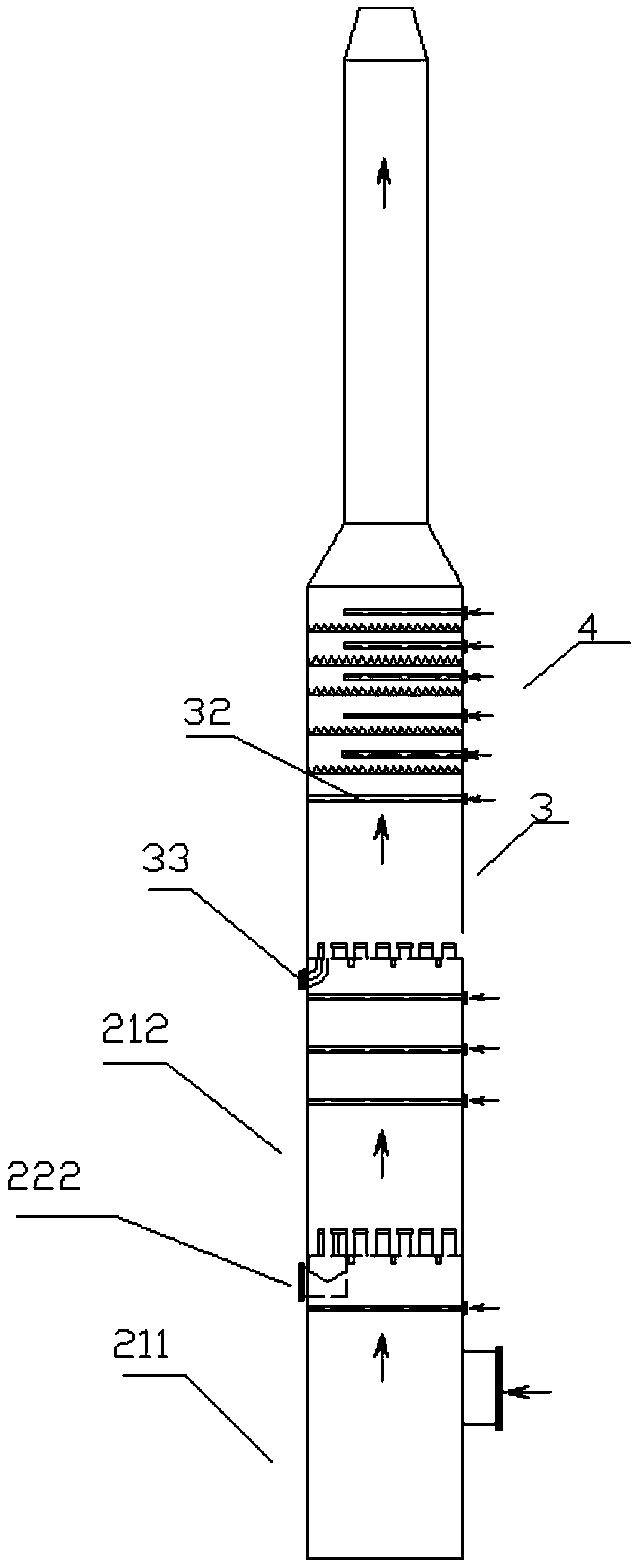

[0037] Circulation desulfurization equipment 2 comprises desulfurization tower 21 and circulation equipment 22; Desulfurization tower 21 comprises interconnected quench section 211 and SO 2 The absor...

Embodiment 2

[0039] Ammonia escape equipment 3 is also included; ammonia escape equipment includes ammonia escape pump 31, ammonia gas absorption liquid backflow device 33 and ammonia gas absorption liquid nozzle 32; ammonia escape pump 31 inlet is connected with ammonia gas absorption liquid backflow device 33, and outlet is connected with ammonia gas Absorbing liquid nozzle 32; ammonia absorbing liquid reflux device 33 is arranged in desulfurization tower 21 SO 2 Above the absorbing section 212, the ammonia gas absorbing liquid nozzle 32 is arranged above the ammonia gas absorbing liquid reflux device 33 in the desulfurization tower.

Embodiment 3

[0040] Embodiment 3: It also includes a mist removal device 4 , which is arranged above the ammonia gas absorption liquid spray nozzle 32 in the desulfurization tower 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com