Silver-containing nanocomposite antibacterial coating and preparation method thereof

A composite antibacterial and silver nanotechnology, used in coatings, paints containing biocides, antifouling/underwater coatings, etc. Effect, low cost, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

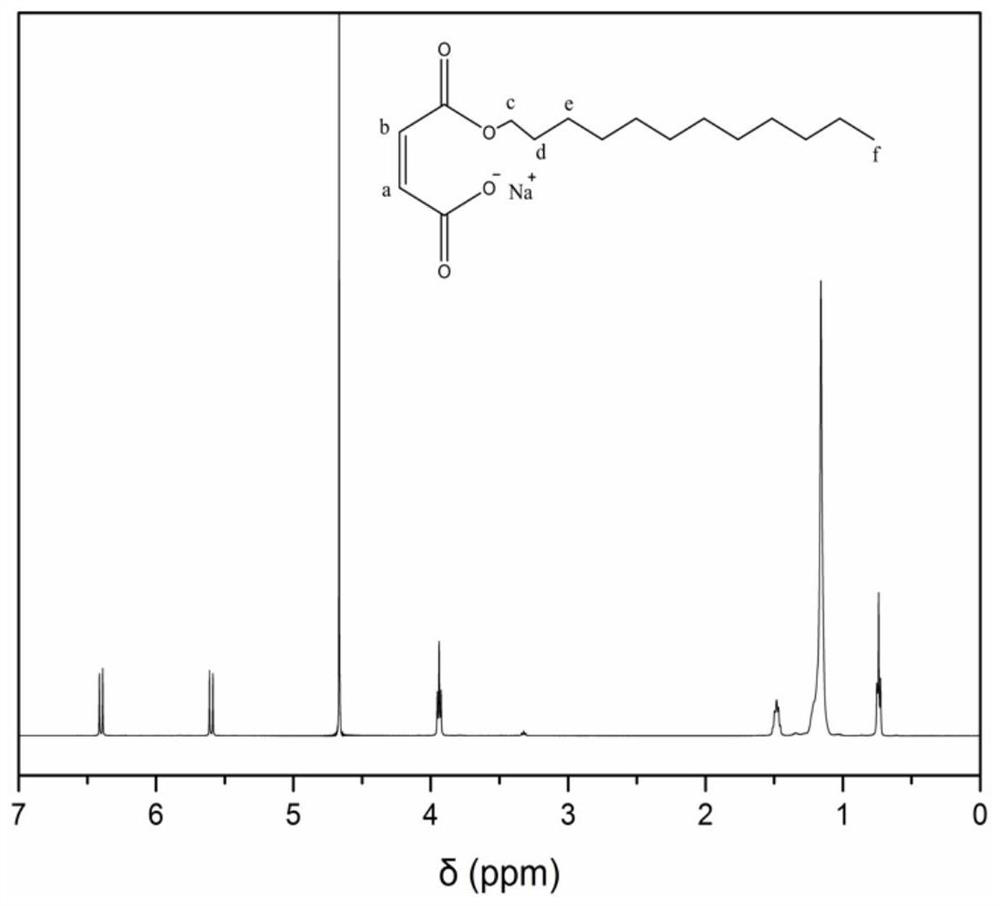

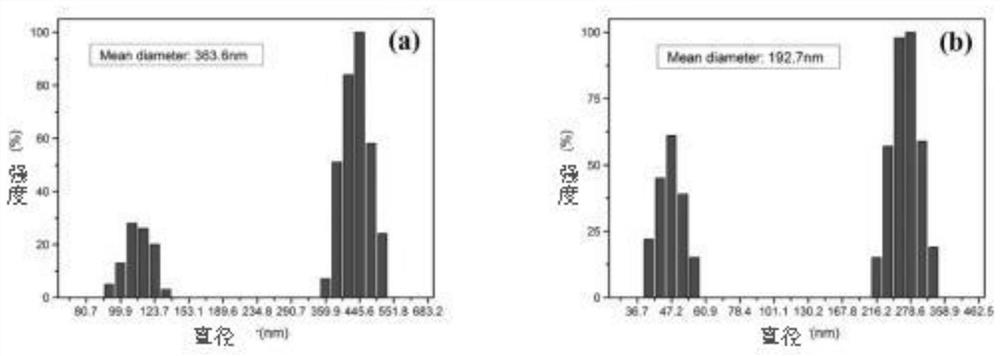

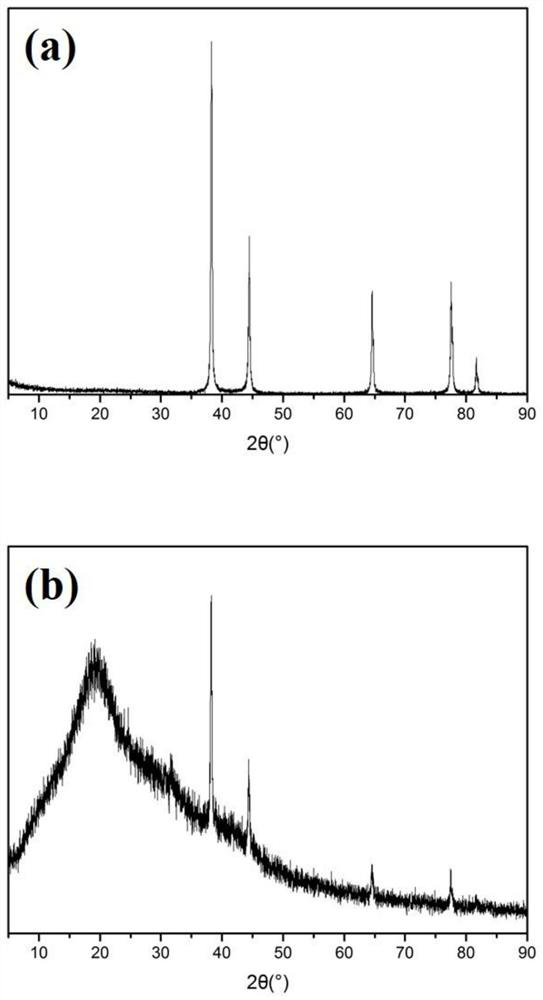

[0040] Preparation of P (Mma-Co-Ba-Co-MAMS) / Ag Nanocomposite Antibacterial Coating:

[0041] (1) Weigh 0.5 g mams, 0.057 g of initiator KPS, dissolved in 50 ml of deionized water, and then weigh 5 g of oxycrylate and 5 g of methyl methacrylate, added to 100 ml of four flasks, at 700 rpm The rotational speed was prepared for 2 h, and the pre-emulsion was added to the constant pressure drip funnel after completion;

[0042] (2) 0.5 g of nanoparticles and 0.5 g mams were dispersed in 50 ml deionized water, and the ultrasonic dispersion of JY92-II N-type ultrasonic cell pulverizer was used. The set parameters were: power 600W, working hours 3s, intermittent time 2s, Ultrasound is 30 minutes in an ice bath, and the ultrasonic dispersion is added to 250 ml of four flasks; 5 g of butyl acrylate and 5 g of methyl methacrylate are added, and in a 250 ml of four flasks, the normal temperature water bath pre-emulsified 0.5h, set After the stirring speed is 700 rpm, after 0.5 h, the tempera...

Embodiment 2

[0046] (1) Weigh 0.5 g mams, 0.057 g of initiator KPS, dissolved in 50 ml of deionized water, and then weigh 5 g of oxycrylate and 5 g of methyl methacrylate, added to 100 ml of four flasks, at 700 rpm The rotational speed was prepared for 2 h, and the pre-emulsion was added to the constant pressure drip funnel after completion;

[0047] (2) 0.25 g of nanoparticles and 0.5 g mams were dispersed in 50 ml deionized water, and the ultrasonic dispersion of JY92-II N-type ultrasonic cell pulverizer was used. The set parameters were: power 600W, working hours 3s, intermittent time 2s, Ultrasound is 30 minutes in an ice bath, and the ultrasonic dispersion is added to 250 ml of four flasks; 5 g of butyl acrylate and 5 g of methyl methacrylate are added, and in a 250 ml of four flasks, the normal temperature water bath pre-emulsified 0.5h, set After the stirring speed is 700 rpm, after 0.5 h, the temperature is started; the temperature reaches 65 ° C, weighs 0.057 g kps, dissolved in a sma...

Embodiment 3

[0051] (1) Weigh 0.5 g mams, 0.057 g of initiator KPS, dissolved in 50 ml of deionized water, and then weigh 5 g of oxycrylate and 5 g of methyl methacrylate, added to 100 ml of four flasks, at 700 rpm The rotational speed was prepared for 2 h, and the pre-emulsion was added to the constant pressure drip funnel after completion;

[0052] (2) 1.0 g of nanoparticles and 0.5 g mams were dispersed in 50 ml deionized water, and the ultrasonic dispersion of JY92-II N-type ultrasonic cell pulverizer was used. The set parameters were: power 600W, working time 3s, intermittent time 2s, Ultrasound is 30 minutes in an ice bath, and the ultrasonic dispersion is added to 250 ml of four flasks; 5 g of butyl acrylate and 5 g of methyl methacrylate are added, and in a 250 ml of four flasks, the normal temperature water bath pre-emulsified 0.5h, set After the stirring speed is 700 rpm, after 0.5 h, the temperature is started; the temperature reaches 66 ° C, weigh 0.057 g kps, dissolve in a small a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com