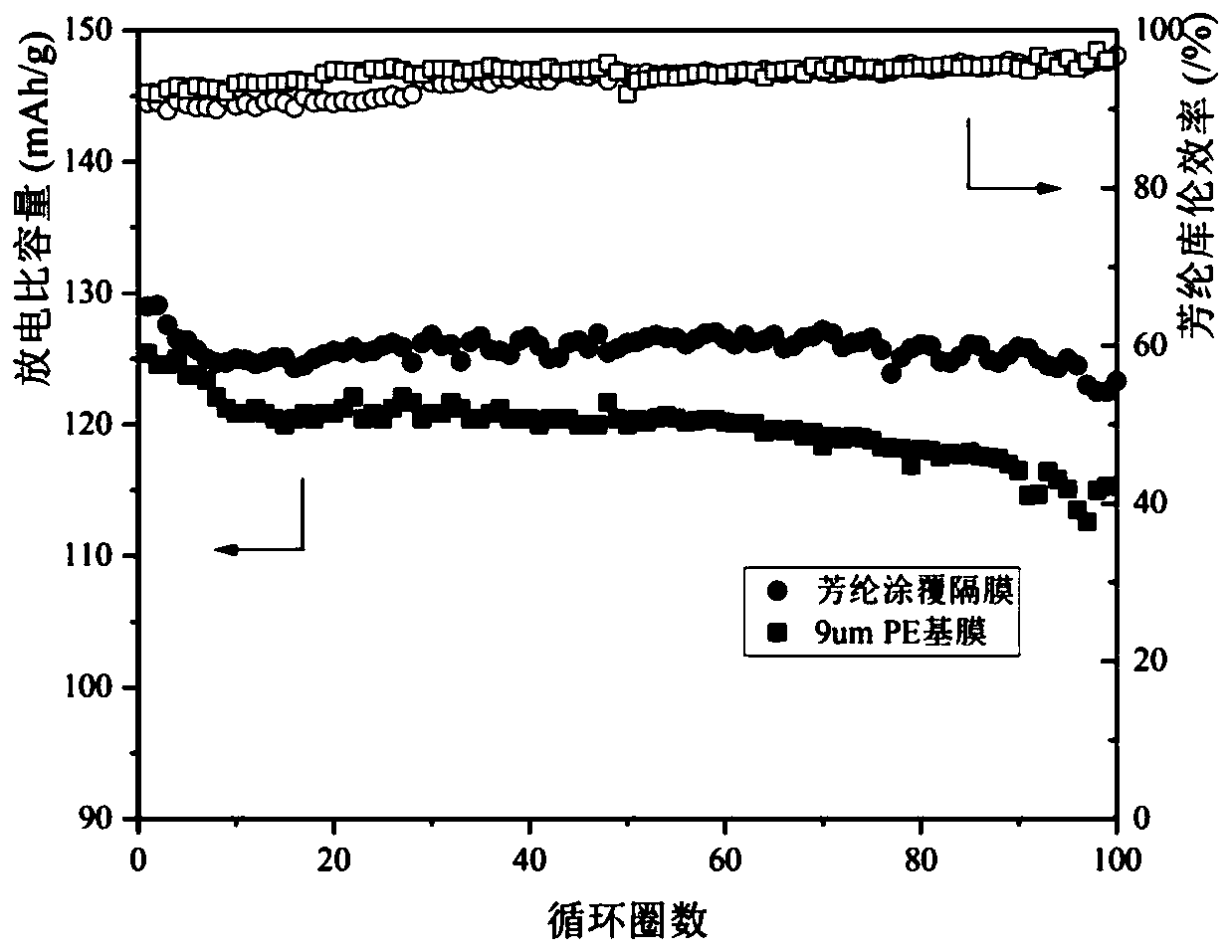

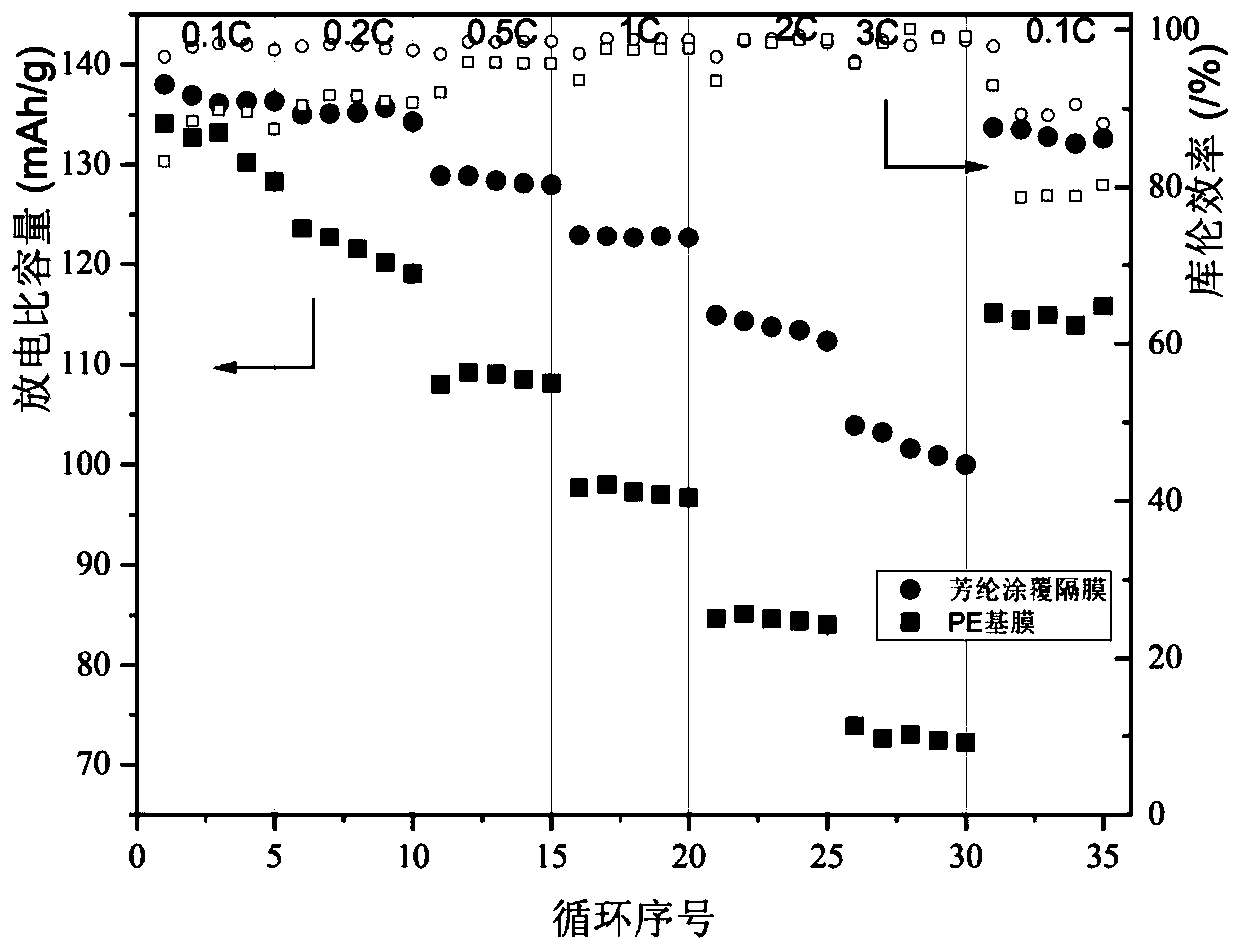

Water-based aramid fiber coating liquid, preparation method thereof, lithium ion battery and diaphragm of lithium ion battery

A lithium-ion battery and coating liquid technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of poor bonding force between the coating and the base film, difficulty in controlling the uniformity of pores, etc., and achieve enhanced adhesion Junction effect, excellent battery performance, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Based on the same inventive concept of the foregoing embodiments, in some optional embodiments, a method for preparing the water-based aramid coating solution without adding the silane solution in the foregoing embodiments is provided, specifically comprising the following steps:

[0053] Take 100 parts by mass of aramid nanofiber aqueous dispersion solution, add 0.25-3 parts by mass of adhesive, 0.2-3 parts by mass of lubricant, 0.1-3 parts by mass of active agent, and 0.3-5 parts by mass of pore-forming agent , after stirring for 0.5 hours to 2 hours in the temperature range of 15° C. to 50° C., the water-based aramid fiber coating liquid is obtained.

[0054] Based on the same inventive concept of the foregoing embodiments, in some optional embodiments, a method for preparing the water-based aramid coating solution added with the silane solution in the foregoing embodiments is provided, specifically comprising the following steps:

[0055] Take 100 parts by mass of t...

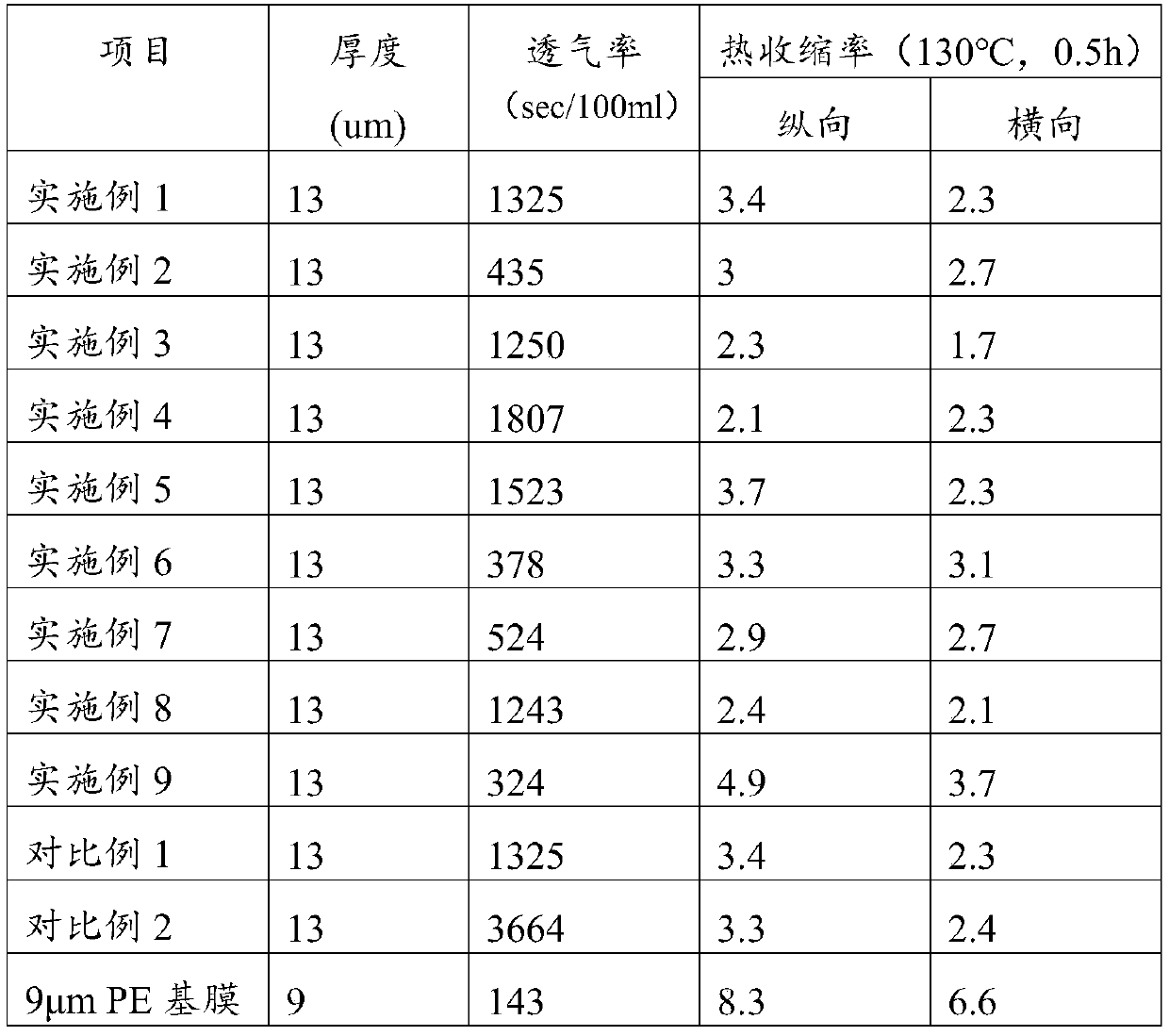

Embodiment 1

[0064] Embodiment 1: the solid content after getting 100ml homogeneous is that the aramid fiber aqueous dispersion of 0.5wt% is in the flask, adds the silane solution that contains 0.3ml TEOS (tetraethyl orthosilicate), 3ml NH H O (pure After diluting ammonia water and deionized water at a volume ratio of 1:3), stir at room temperature (25°C) for 12 hours, then add 0.5g of acrylic binder, 0.75g of surfactant, and 2ml of pore-forming agent butanol in sequence. Stir at room temperature for 0.5h, then scrape-coat on the surface of a 9μm PE base film, and dry at 70°C to obtain an aramid-coated composite separator.

Embodiment 2

[0065]Example 2: Take 100ml homogeneous 0.5wt% aramid aqueous dispersion in a flask, add silane solution containing 0.5ml TEOS, 3ml NH3 H2O (dilute pure ammonia water and deionized water at a volume ratio of 1:3 ), stirred at room temperature (25° C.) for 12 h, and then added 0.5 g of acrylic binder, 0.75 g of surfactant, and 2 ml of pore-forming agent butanol in sequence. Stir at room temperature for 0.5h, then scrape-coat on the surface of 9μm PE base film, and dry at 70°C to obtain aramid-coated composite separator. With the addition of TEOS, the air permeability of the separator increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com