Method for constructing cartilage patch stent based on polycaprolactone electrostatic spinning 3D printing and device thereof

An electrospinning and polycaprolactone technology, applied in the medical field, can solve problems such as difficult stent area, thickness modification, and inability to adjust the internal structure design of the stent, so as to improve biomechanical properties, superior biomechanical properties, and broaden applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for constructing a cartilage patch scaffold based on polycaprolactone electrospinning 3D printing, including the following steps:

[0042] (1) Carry out individualized design to the characteristic parameters of the stent according to the individual characteristics;

[0043] (2) Using electrospinning 3D printing technology, polycaprolactone is used as a raw material, and the cartilage patch bracket is printed according to the individualized 3D model;

[0044] (3) After the chondrocytes are extracted and proliferated, the cells are induced to proliferate on the scaffold and secrete the cell matrix to form a complete cartilage patch.

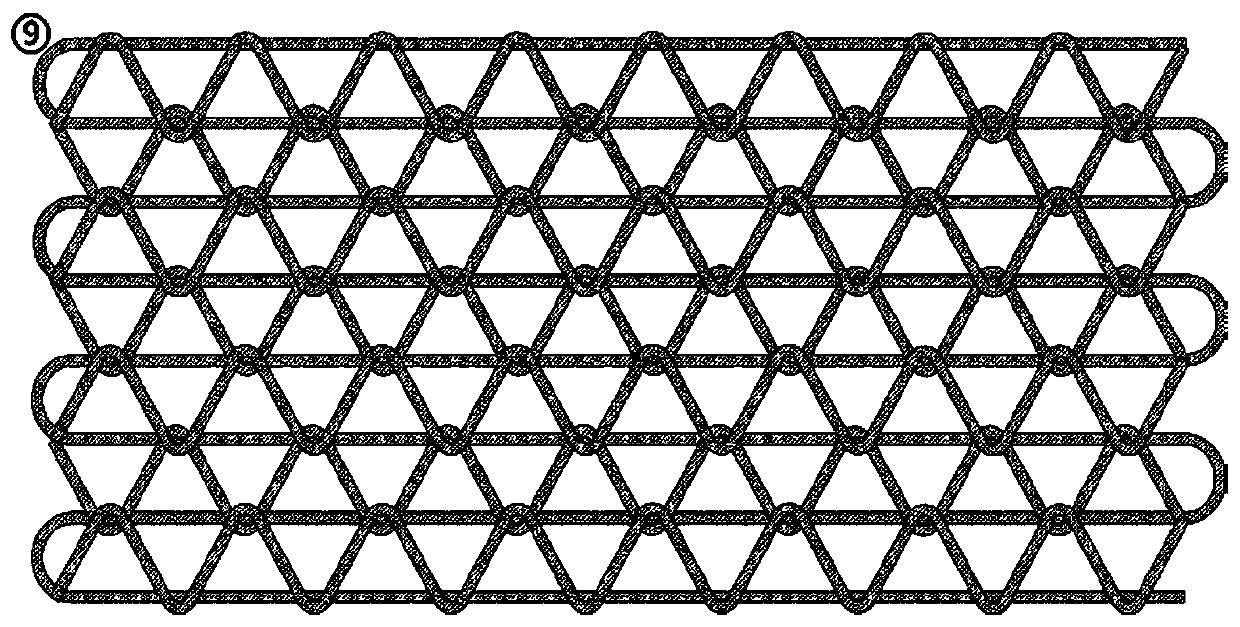

[0045] In this example, if figure 2 , image 3 Among them, the electrospinning described in the step (2) adopts wave-shaped and linear stacked arrangements.

[0046] In this example, if figure 2 , image 3 Among them, the cartilage patch support in step (2) adopts a hollow structure, and the shape of ...

Embodiment 2

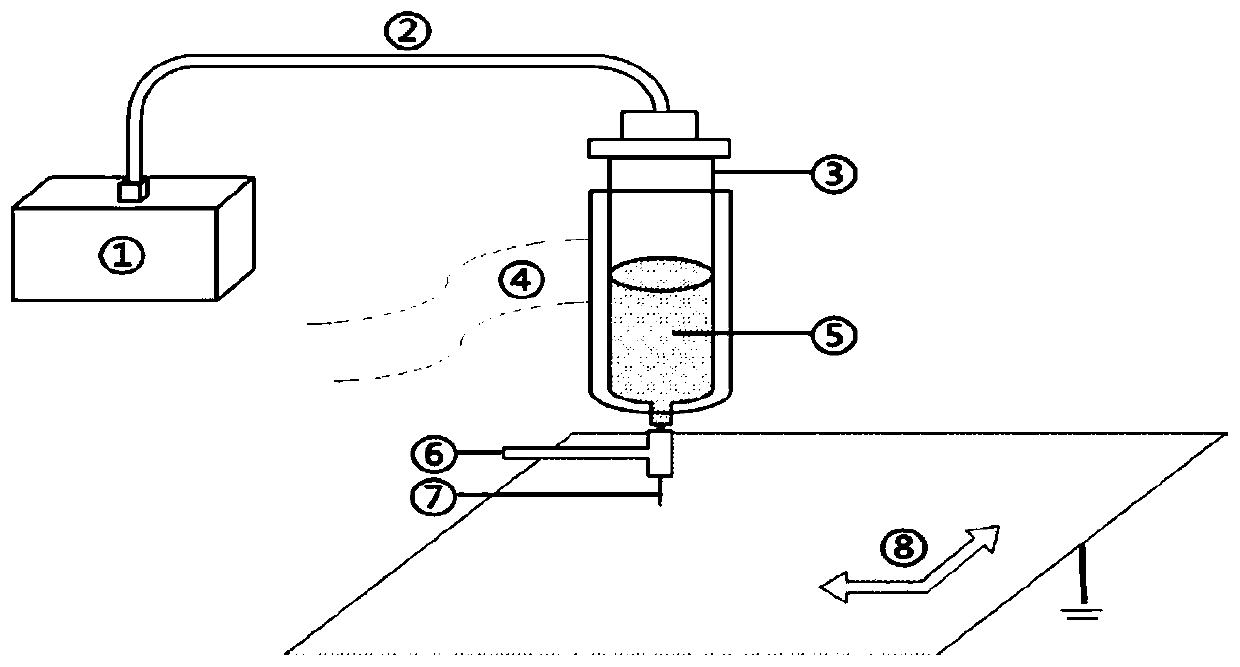

[0052] see figure 1 As shown, this embodiment provides a cartilage patch scaffold construction device based on polycaprolactone electrospinning 3D printing, including a material bucket 3 and a table moving device 8, the material bucket 3; the bottom of the material bucket 3 is provided with a printer nozzle 7 and a high-voltage electrode 6; the high-voltage electrode 6 and the table grounding device on the table moving device 8 jointly build an electric field strength to form electrospinning.

[0053] In this example, if figure 1 In the step (2), the 3D printing device further includes: an air pump device 1, a material barrel 3 connected to the air pump device 1 through an air guide tube 2, and a heating device 4 for heating the material 5 in the material barrel 3 , a printer nozzle 7, a table mobile device 8 and a control unit equipped with 3D printing intelligent control software.

[0054] In this example, if figure 1 Among them, a control unit and a heating device 4 are ...

Embodiment 3

[0060] Using the polycaprolactone electrospinning 3D printing cartilage patch scaffold construction method described in Example 1 to construct a cartilage patch scaffold for clinical use includes the following steps.

[0061] (1) Individually design the shape and structure of the patch as needed, and build a 3D model.

[0062] (2) Through 3D printing combined with electrospinning technology, using PCL as a raw material, the pre-built 3D model was printed to form a cell scaffold.

[0063] (3) Extract primary chondrocytes for expansion, plant the amplified chondrocytes on PCL cell scaffolds, and culture them in a specific environment. Chondrocytes are amplified on the scaffolds and secrete extracellular matrix to form chondrocytes- Extracellular matrix-scaffold complex.

[0064] (4) The complex is transplanted subcutaneously for vascularization, so that it has more perfect biological performance.

[0065] (5) Orthotopic transplantation of the vascularized chondrocyte-extracell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com