Method for simultaneously preparing shiny-leaved yellowhorn oil and shiny-leaved yellowhorn protein through aqueous enzymatic method

A technology of sorbifolia oil and water enzymatic method, which is applied to the preparation method of peptides, chemical instruments and methods, fat oil/fat production, etc., can solve the problem that the cake can only be used as animal feed, the human body and the environment are greatly affected, and the fat Quality restrictions and other issues, to achieve the effect of reduced possibility, low cost, and reduced flammability and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

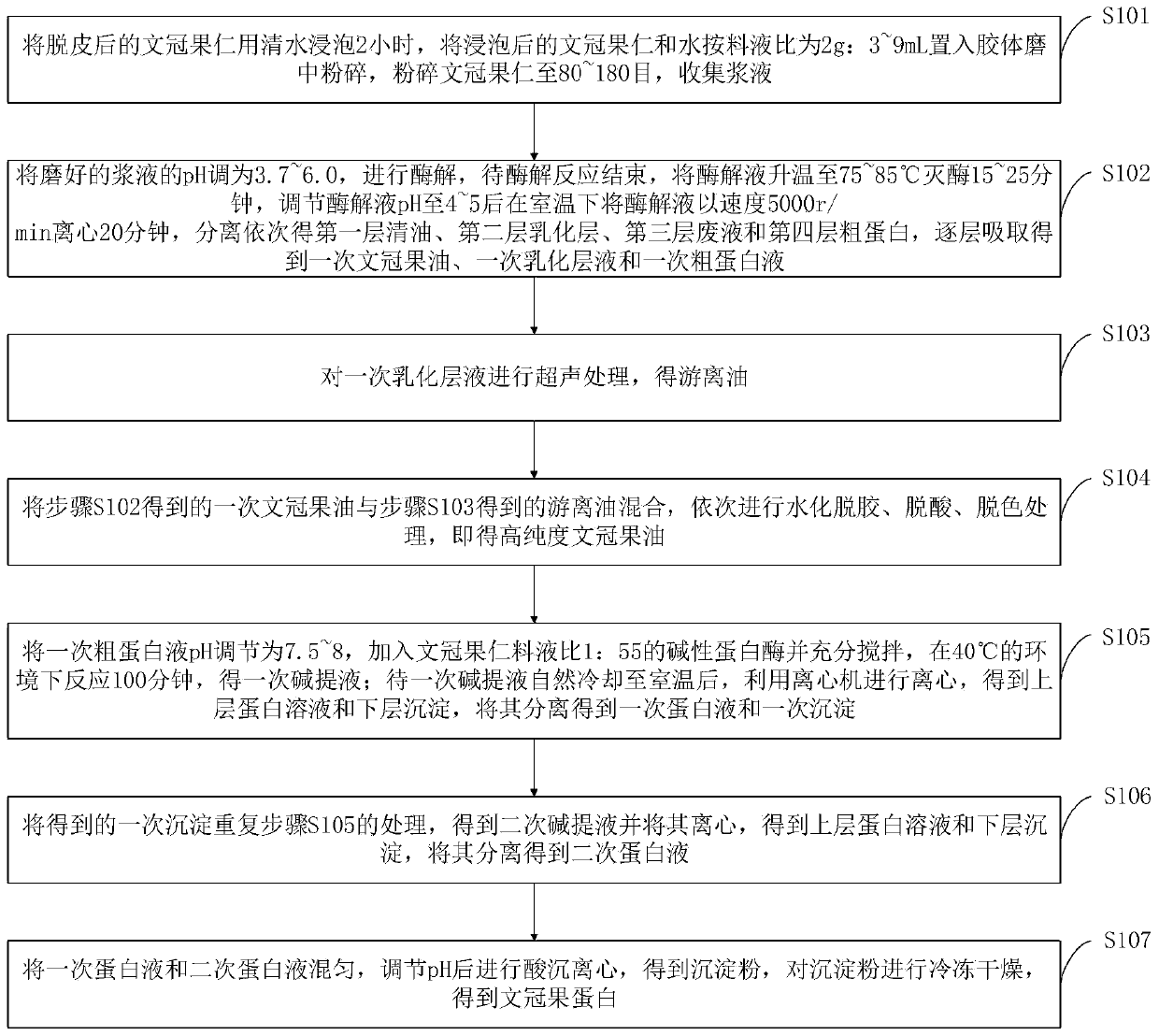

[0067] A kind of aqueous enzymatic method that the embodiment of the present invention 1 provides simultaneously prepares the method for sorbia sorbifolium oil and radix sorbifolium protein and comprises the following steps:

[0068] (1) Slurry acquisition: put the peeled X. sorbifolia nuts and water into a colloid mill at a material-to-liquid ratio of 2 g: 3 mL, crush the X. radix radix kernels to 80 mesh, and collect the slurry.

[0069] (2) Enzymolysis: Adjust the pH of the slurry ground in step 1 to 3.7, add pectinase and cellulase for enzymolysis, and perform enzymolysis in a water bath at 45°C for 2.5 hours. After the enzymatic hydrolysis reaction is completed, heat the enzymatic hydrolysis solution to 75°C to inactivate the enzyme for 15 minutes, adjust the pH of the enzymatic hydrolysis solution to 4, and then centrifuge. Centrifuge the enzymatic solution to obtain the first layer of clear oil, the second layer of emulsified layer, the third layer of waste liquid, and ...

Embodiment 2

[0076] A kind of aqueous enzymatic method that the embodiment of the present invention 2 provides simultaneously prepares the method for sorbia sorbifolium oil and radix sorbifolium protein and comprises the following steps:

[0077] (1) Slurry acquisition: put the peeled X. sorbifolia nuts and water into a colloid mill at a material-to-liquid ratio of 2 g: 5 mL, crush the X. sorbifolia nuts to 120 mesh, and collect the slurry.

[0078] (2) Enzymolysis: adjust the pH of the slurry ground in step 1 to 5.0, add pectinase and cellulase for enzymolysis, and perform enzymolysis in a water bath at 50° C. for 4 hours. After the enzymatic hydrolysis reaction is completed, heat the enzymatic hydrolysis solution to 80°C to inactivate the enzyme for 20 minutes, adjust the pH of the enzymatic hydrolysis solution to 4.5, and then centrifuge. Centrifuge the enzymatic solution to obtain the first layer of clear oil, the second layer of emulsified layer, the third layer of waste liquid, and t...

Embodiment 3

[0085] A kind of aqueous enzymatic method that the embodiment of the present invention 3 provides simultaneously prepares the method for sorbia sorbifolium oil and sorbia sorbifolium protein and comprises the following steps:

[0086] (1) Slurry acquisition: put the peeled X. sorbifolia nuts and water into a colloid mill at a material-to-liquid ratio of 2 g: 9 mL, crush the X. radix radix kernels to 160 mesh, and collect the slurry.

[0087] (2) Enzymolysis: adjust the pH of the slurry ground in step 1 to 6.0, add pectinase and cellulase for enzymolysis, and perform enzymolysis in a water bath at 65° C. for 5.5 hours. After the enzymatic hydrolysis reaction is completed, heat the enzymatic hydrolysis solution to 85°C to inactivate the enzyme for 25 minutes, adjust the pH of the enzymatic hydrolysis solution to 5, and then centrifuge. Centrifuge the enzymatic solution to obtain the first layer of clear oil, the second layer of emulsified layer, the third layer of waste liquid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com