Organic porous nanoparticle/surfactant composite oil displacement system and preparation method thereof

A surfactant and nanoparticle technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of oil displacement without surfactant synergistic effect, reduce the economical efficiency of surfactant flooding, and increase engineering operation. cost and other issues, to achieve the effect of synergistic surfactant flooding, good temperature resistance and salt resistance, and the effect of improving oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add the mixture of 10g styrene and 0.5g divinylbenzene dropwise into 100g deionized water dissolved with 0.2g sodium lauryl sulfate, and at the same time stir and emulsify at a speed of 300 rpm, styrene, divinylbenzene Continue to stir and emulsify for 1 hour after the benzene mixture is added dropwise. After the emulsification is completed, pass nitrogen gas to remove oxygen for 15 minutes and raise the temperature of the emulsion to 80° C. and add 5 g of potassium persulfate in water to initiate the reaction. The mass concentration of potassium persulfate in water is 3%. During the reaction, the stirring rate was kept at 300 rpm, and the reaction was completed after 8 hours. Add ethanol to the reacted emulsion to break the emulsion, then centrifuge the cross-linked polystyrene nanospheres, wash the cross-linked polystyrene nanospheres with ethanol several times and then dry them to obtain the dry cross-linked polystyrene nanospheres product.

[0044] Disperse 2.5 g o...

Embodiment 2

[0047] Add the mixed solution of 8g styrene and 0.2g divinylbenzene dropwise into 100g deionized water dissolved with 0.24g sodium lauryl sulfate, and at the same time stir and emulsify at a speed of 350 rpm, styrene, divinylbenzene Continue to stir and emulsify for 1 hour after the benzene mixture is added dropwise. After the emulsification is completed, pass nitrogen gas to deoxygenate for 15 minutes and raise the temperature of the emulsion to 80° C. and add 3.3 g of potassium persulfate aqueous solution to initiate the reaction. The mass concentration of potassium persulfate aqueous solution is 3 %, the stirring rate was kept at 350 rpm during the reaction, and the reaction was completed after 8 hours. Add ethanol to the reacted emulsion to break the emulsion, then centrifuge the cross-linked polystyrene nanospheres, wash the cross-linked polystyrene nanospheres with ethanol several times and then dry them to obtain the dry cross-linked polystyrene nanospheres product.

...

Embodiment 3

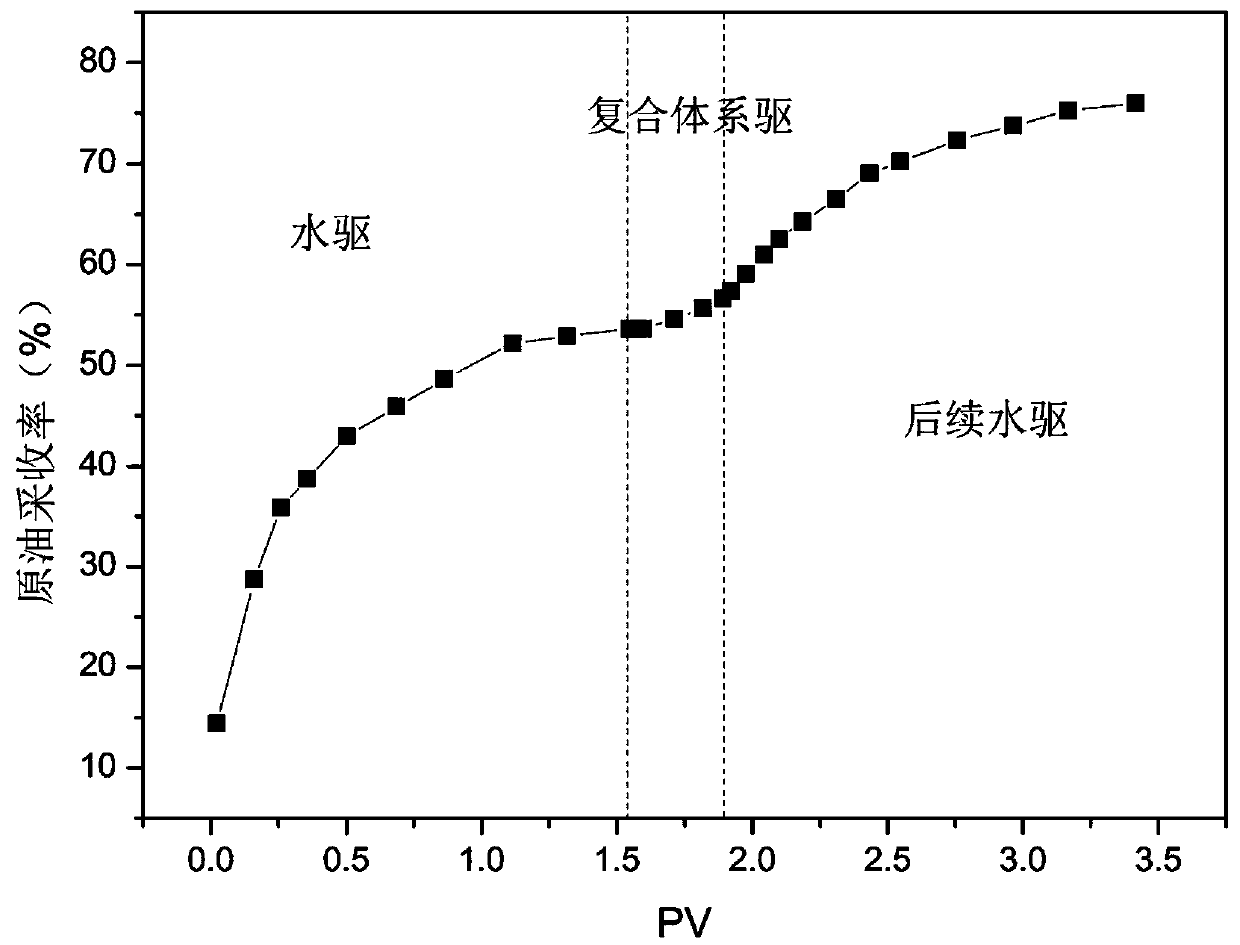

[0051] Using the organic porous nanoparticle / surfactant composite oil displacement system prepared in Example 1 and the 0.2% alcohol ether carboxylate aqueous solution to carry out sand-packing pipe displacement experiments under the same conditions, the sand-packing experiments in the displacement experiments The inner diameter of the model is 25mm, the length is 500mm, the porosity is about 30%, and the permeability is about 0.8μm 2 , the temperature condition is room temperature, and the displacement rate is 0.2mL / min. The dynamic adsorption amount of surfactant is calculated according to the change of alcohol ether carboxylate concentration in the core production fluid, and the change of alcohol ether carboxylate concentration is measured by ultraviolet spectrophotometry Compared with the 0.2% alcohol ether carboxylate aqueous solution, the dynamic adsorption capacity of the surfactant in the organic porous nanoparticle / surfactant composite flooding system of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bet surface area | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com