Cellulose nanocrystal hydrophobic porous powder and preparation method thereof

A technology of porous powder and nanocrystal, which is applied in the field of cellulose nanocrystal hydrophobic porous powder and its preparation, can solve the problems of high energy consumption, solvent environmental pollution, etc., and achieves improved heat resistance, improved compatibility, and improved reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

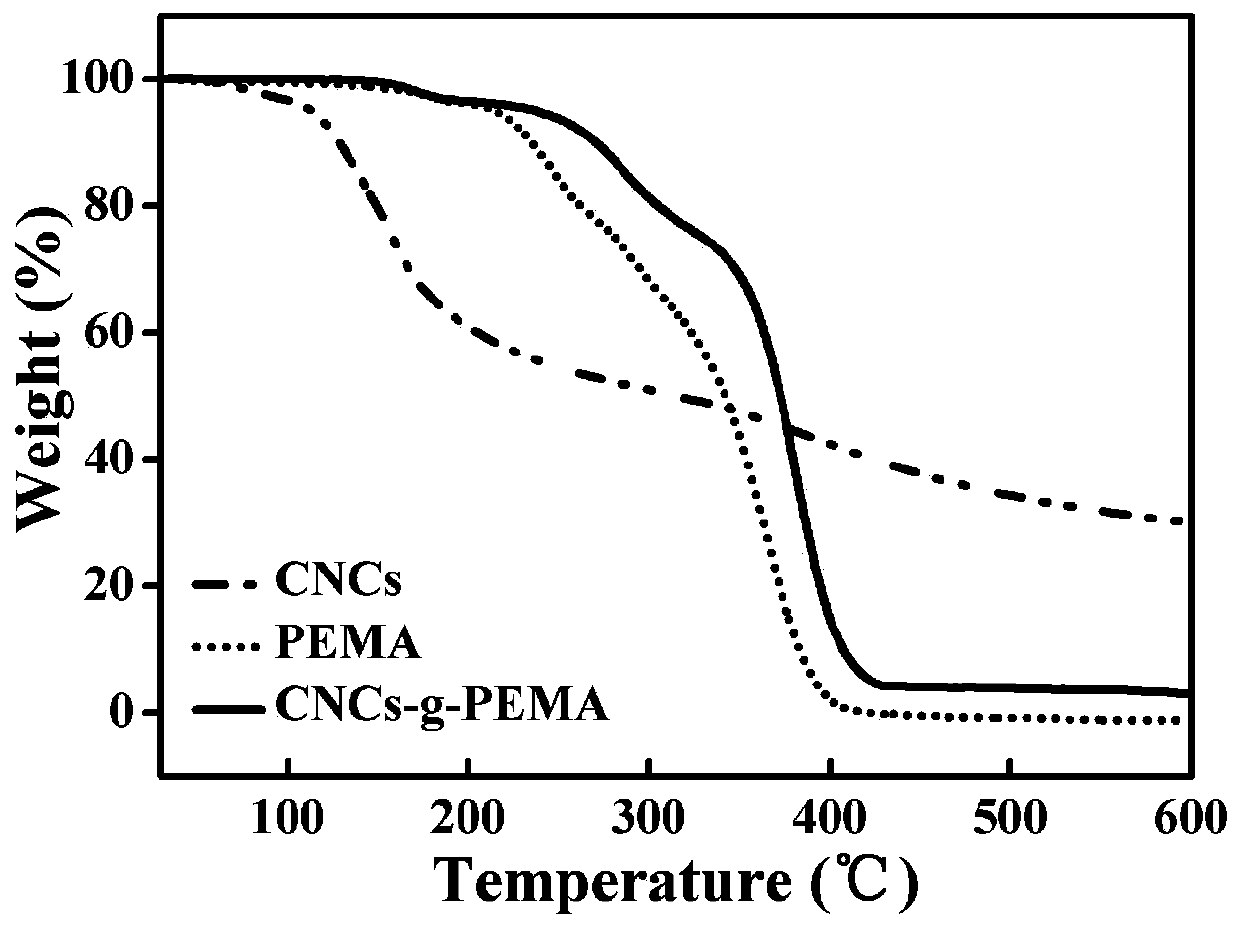

[0037] 20 mL of 1% sulfonated cellulose nanocrystal water suspension was added into a three-neck flask, dilute sulfuric acid was added to adjust the pH=4, and 0.1 g of ceric ammonium nitrate and 1 g of ethyl methacrylate were added after ultrasonication. After fully stirring, keep the temperature at 65°C. After reacting for 2 hours, take it out and wash until neutral, and dry it in a blast drying oven to obtain a white cellulose nanocrystalline porous powder. The grafting rate of polyethyl methacrylate is 350%, and the grafting efficiency is 72%. The powder size is 80μm, and the average pore size is 500nm.

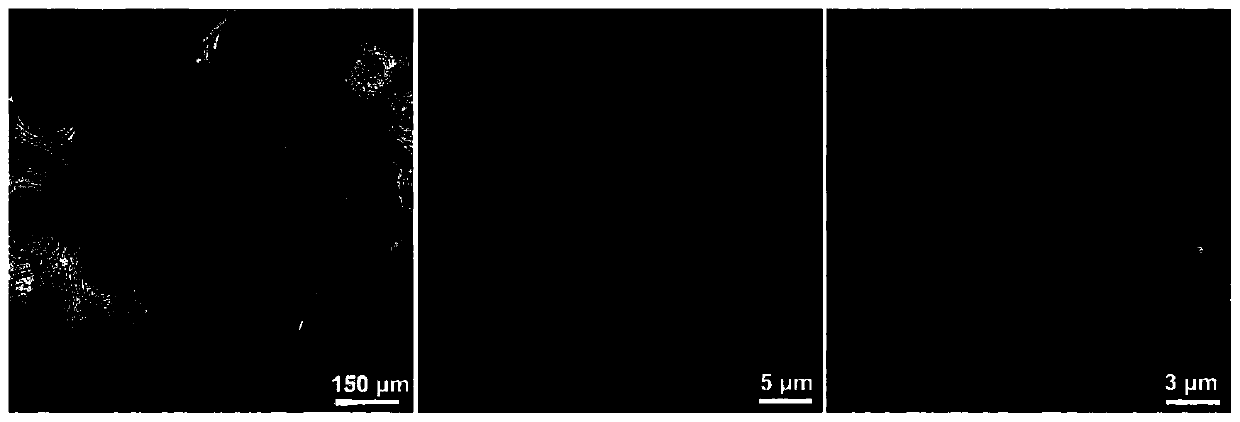

[0038] The photographs and scanning electron microscope photographs of the prepared cellulose nanocrystalline porous powder are as follows: figure 1 and figure 2 shown. From figure 1 It can be seen that the cellulose nanocrystalline porous powder prepared by this method is a white powder with uniform size; figure 2 It can be seen that the cellulose nanocrystalline p...

Embodiment 2

[0041] The types of raw materials used and the process flow are the same as in Example 1, except that the amount of ethyl methacrylate is 0.6 g to obtain a cellulose nanocrystalline porous powder. The measured polyethyl methacrylate grafting rate is 250%, and the grafting efficiency is 85%. The obtained cellulose nanocrystalline porous powder has an average size of 50 μm and an average pore diameter of 200 nm.

Embodiment 3

[0043] The types of raw materials used and the process flow are the same as in Example 1, except that the amount of ethyl methacrylate is 2 g to obtain a cellulose nanocrystalline porous powder. The measured polyethyl methacrylate grafting rate is 600%, and the grafting efficiency is 65%. The obtained cellulose nanocrystalline porous powder has an average size of 120 μm and an average pore diameter of 1200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com