All-printed mesoscopic perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor process repeatability of mesoscopic perovskite solar cells, degradation of solar cell device performance, and difficult crystallization, etc., to achieve Good prospects for industrialization, solving poor repeatability and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

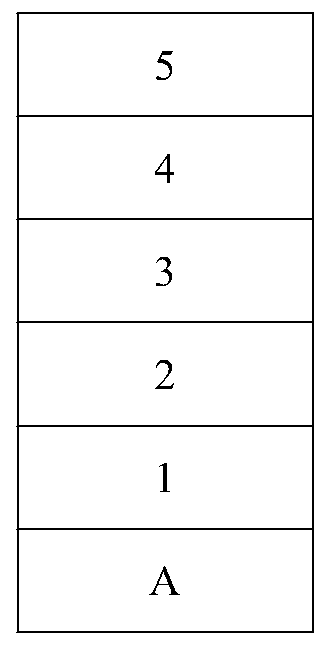

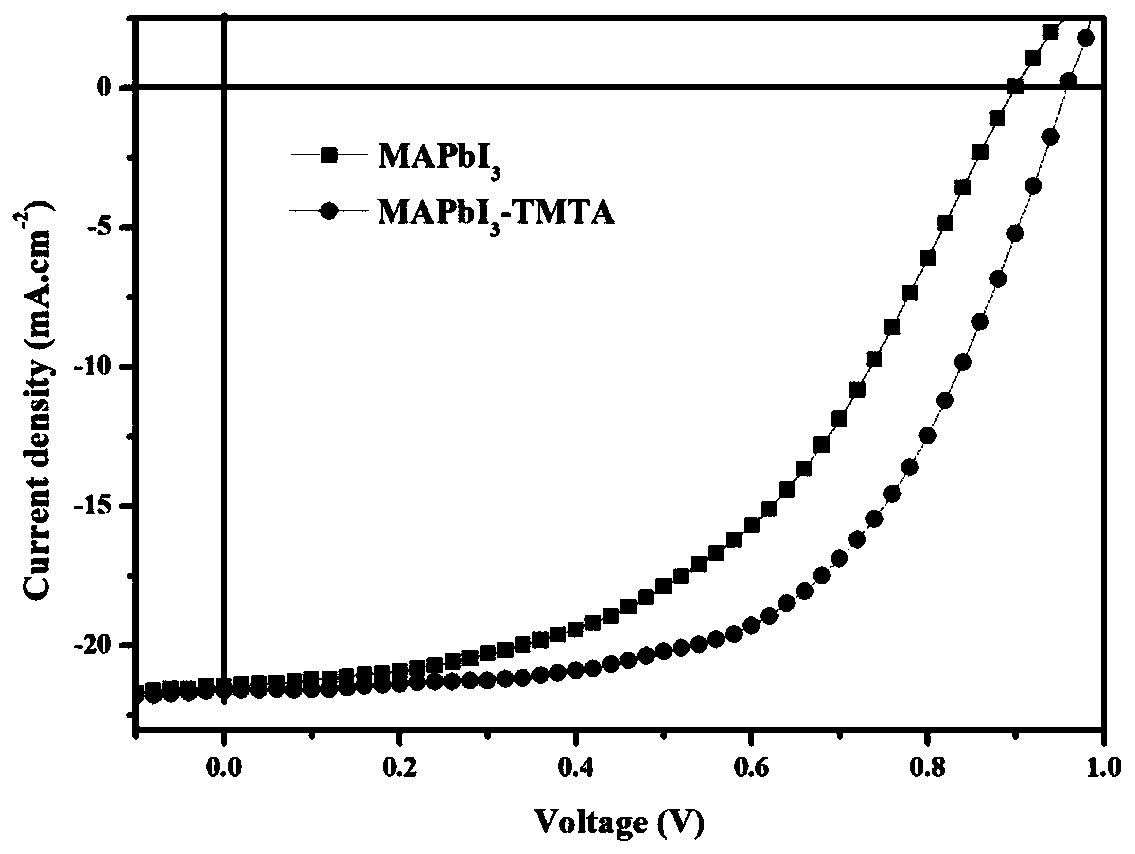

[0029] A cathode layer 1 , an electron transport layer 2 , a mesoporous layer 3 , a barrier layer 4 , and an anode layer 5 are sequentially printed on the upper surface of an ITO glass substrate. The thickness of the electron transport layer is 10nm, the thickness of the mesoporous layer is 200nm, the thickness of the barrier layer is 0.1um, and the thickness of the anode layer is 2um. The cathode layer is ITO. The electron transport layer is TiO 2 . The mesoporous layer is TiO 2 . The barrier layer is ZrO 2 , one of MgO. After the preparation is completed, the precursor solution of the perovskite film with a concentration of 2M and trimethylolpropane triacrylate added is drop-coated on the anode layer 5, and allowed to diffuse freely. After 30 minutes, the perovskite film is filled in the The mesoporous layer, the barrier layer and the anode layer were annealed at 250°C for 30 minutes to prepare a fully printed perovskite solar cell. The concentration of trimethylolpro...

Embodiment 2

[0032] A cathode layer 1, an electron transport layer 2, a mesoporous layer 3, a barrier layer 4, and an anode layer 5 are sequentially prepared on the upper surface of the FTO glass substrate. The electron transport layer has a thickness of 100nm, the mesoporous layer has a thickness of 2000nm, the barrier layer has a thickness of 5um, and the anode layer has a thickness of 30um. The cathode layer is FTO. The electron transport layer is SnO 2 , One of ZnO. The mesoporous layer is SnO 2 . The barrier layer is Al 2 o 3 . After the preparation is completed, a precursor solution with a concentration of 2M and a perovskite film added with pentaerythritol tetraacrylate is dropped on the anode layer 5 to allow it to diffuse freely. After 10 minutes, it is annealed at 100°C for 30 minutes. Fabricated fully printed perovskite solar cells. The concentration of pentaerythritol tetraacrylate in the precursor solution of the perovskite thin film is 30wt%. The perovskite film is F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com