Phosphaphenanthrene group modified zirconium phosphate-based flame retardant and preparation method thereof

A technology of phosphaphenanthrene group and zirconium phosphate, which is applied in the field of flame retardants based on phosphaphenanthrene group modified zirconium phosphate and its preparation, can solve the problem of poor carbon quality, low flame retardant efficiency, and loose carbon layer strength. Low problems, to achieve the effect of taking into account chemical stability, high flame retardant efficiency, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

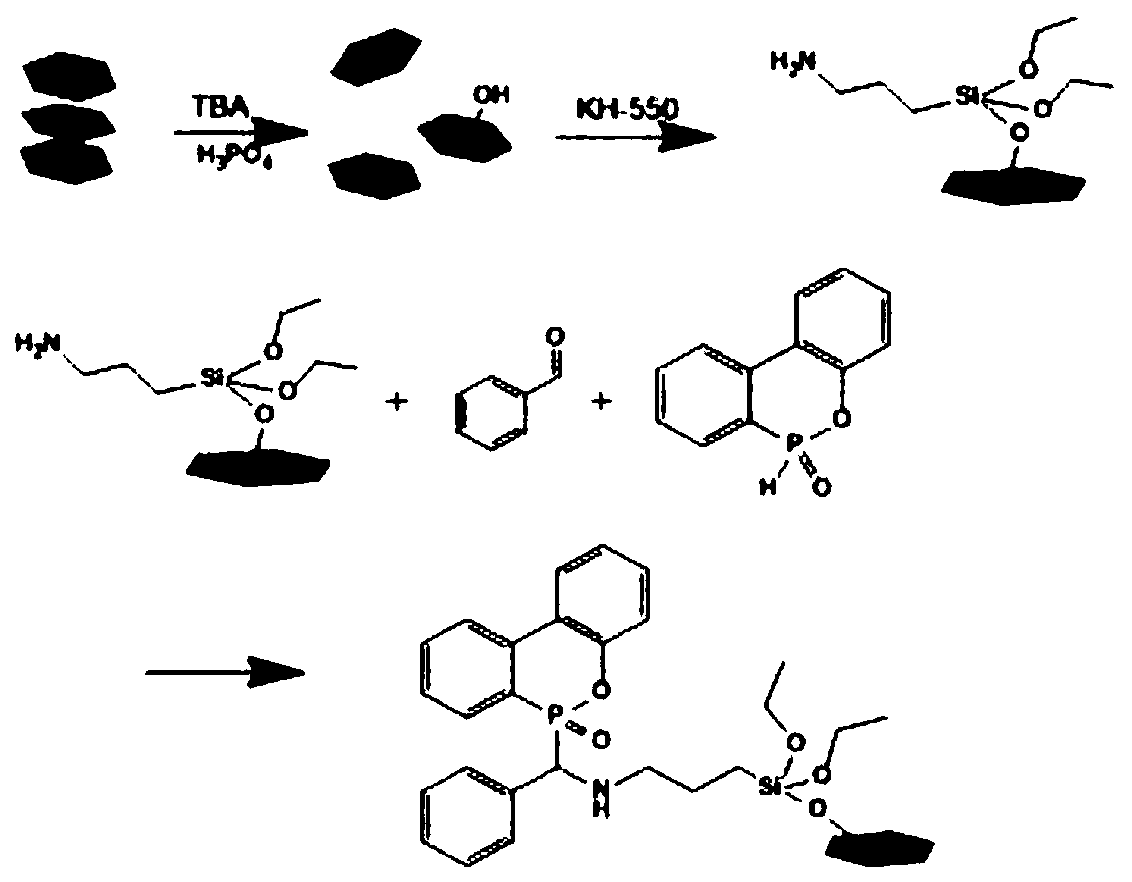

[0040] A flame retardant based on phosphaphenanthrene group-modified zirconium phosphate, the synthetic route involved is shown in figure 1 , the specific preparation method comprises the following steps:

[0041] 1) TBA exfoliation of zirconium phosphate: in a 500ml four-neck flask, 3.00g of zirconium phosphate and 300ml of deionized water were fully dispersed by mechanical stirring and ultrasonication. TBA (tetrabutylammonium hydroxide aqueous solution, 25wt%) was added dropwise in the four-necked flask at a constant speed within 30min, and continued to react for 2h after the dripping, and then the 4mol / L concentrated phosphoric acid of 15ml was added dropwise at a constant speed in the flask within 30min. After the reaction (2h), the mixed solution was centrifuged for solid-liquid separation to obtain a translucent gel precipitate and washed with dioxane;

[0042] 2) Grafted silane coupling agent KH550: Add the translucent gel washed in step 1) into a four-necked flask, an...

Embodiment 2

[0047] A kind of flame retardant based on phosphaphenanthrene group modified zirconium phosphate, its preparation method comprises the steps:

[0048] 1) TBA exfoliation of zirconium phosphate: In a 500ml four-necked flask, 6.00ml of zirconium phosphate and 300ml of deionized water were fully dispersed by mechanical stirring and ultrasonication. The process lasted for 30min and kept at a temperature of 5°C. Tetrabutylammonium hydroxide 25wt% aqueous solution), in 30min, be added dropwise in the four-necked flask at a constant speed, continue to react for 2h after dropping, then the 4mol / L concentrated phosphoric acid of 15ml is added dropwise in the flask at a constant speed in 30min, after the reaction finishes, The mixed solution is subjected to solid-liquid separation by centrifugation, and a translucent gel precipitate is obtained and washed with dioxane;

[0049] 2) Grafted silane coupling agent KH550: Add the washed translucent gel into a four-neck flask, add 4.43g KH550...

Embodiment 3

[0052] A kind of flame retardant based on phosphaphenanthrene group modified zirconium phosphate, its preparation method comprises the steps:

[0053] 1) TBA exfoliation of zirconium phosphate: In a 500ml four-necked flask, 1.00g of zirconium phosphate and 150ml of deionized water were fully dispersed by mechanical stirring and ultrasonication. The process lasted for 30min and kept at a temperature of 5°C. (Tetrabutylammonium hydroxide 25wt% aqueous solution), was added dropwise at a constant speed in the four-necked flask within 30min, and continued to react for 2h after the dripping, and then 15ml of 4mol / L concentrated phosphoric acid was added dropwise at a constant speed of 30min in the flask. (2h), the mixed solution is subjected to solid-liquid separation by centrifugation, and a translucent gel precipitate is obtained and washed with dioxane;

[0054] 2) Grafted silane coupling agent KH550: Add the washed translucent gel into a four-necked flask, add 0.74g KH550 and 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com