Ultrahigh-voltage flame-retardant cable material and preparation method thereof

A flame-retardant cable material and ultra-high voltage technology, applied in the field of power cables, can solve the problems of fire scale expansion and poor flame resistance, and achieve the effects of improving flame retardancy and mechanical properties, good weather resistance, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

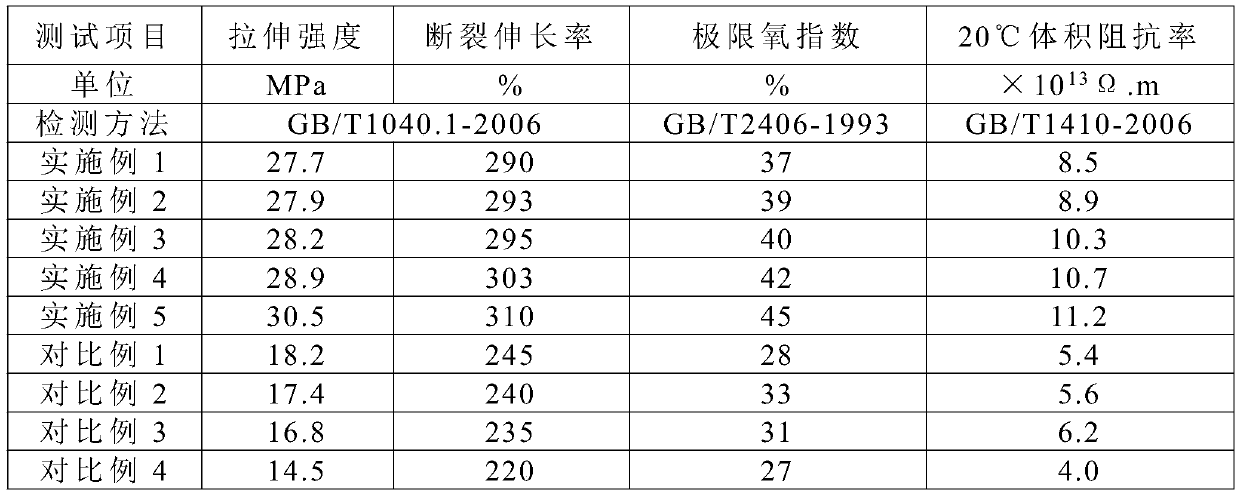

Examples

Embodiment 1

[0030] A method for preparing an ultra-high voltage flame-retardant cable material, comprising the steps of:

[0031] Step S1, polycondensation of 3,3'-(2,4-diamino-6,7-pteridinediyl)diphenol and carboxyl-terminated polyurethane: 3,3'-(2,4-diamino-6,7 -pteridinediyl)diphenol 1kg, carboxyl-terminated polyurethane 1kg, N,N-diisopropylethylamine 0.6kg, 4-dimethylaminopyridine 0.3kg are dissolved in dimethyl sulfoxide 8kg to form a solution, and then the solution Put it into the reaction kettle, replace the air in the kettle with nitrogen, then react at 130°C under normal pressure for 3 hours, then add 0.5kg of thiophosphonate into the reaction system, then raise the temperature to 240°C, and carry out polycondensation reaction at 300Pa for 15 hour, then cooled to room temperature, adjusted to normal pressure, precipitated in water, washed the precipitated polymer with ethanol for 3 times, and finally placed in a vacuum drying oven at 80°C to dry to constant weight to obtain a pol...

Embodiment 2

[0037] A method for preparing an ultra-high voltage flame-retardant cable material, comprising the steps of:

[0038] Step S1, polycondensation of 3,3'-(2,4-diamino-6,7-pteridinediyl)diphenol and carboxyl-terminated polyurethane: 3,3'-(2,4-diamino-6,7 -pteridinediyl)diphenol 1kg, carboxyl-terminated polyurethane 1kg, N,N-diisopropylethylamine 0.6kg, 4-dimethylaminopyridine 0.3kg dissolved in N,N-dimethylformamide 9kg to form Solution, then add the solution into the reaction kettle, replace the air in the kettle with helium, then react at 135°C under normal pressure for 3.5 hours, then add 0.5kg of thiophosphoramide to the reaction system, and then raise the temperature to 250°C, at 350Pa The polycondensation reaction was carried out at room temperature for 17 hours, then cooled to room temperature, adjusted to normal pressure, and precipitated in water. After the precipitated polymer was washed with ethanol for 4 times, it was finally placed in a vacuum drying oven at 83°C and...

Embodiment 3

[0044] A method for preparing an ultra-high voltage flame-retardant cable material, comprising the steps of:

[0045] Step S1, polycondensation of 3,3'-(2,4-diamino-6,7-pteridinediyl)diphenol and carboxyl-terminated polyurethane: 3,3'-(2,4-diamino-6,7 -pteridinediyl)diphenol 1kg, carboxyl-terminated polyurethane 1kg, N,N-diisopropylethylamine 0.6kg, 4-dimethylaminopyridine 0.3kg are dissolved in N-methylpyrrolidone 10kg to form a solution, and then Put the solution into the reaction kettle, replace the air in the kettle with neon, then react at 140°C under normal pressure for 4 hours, then add 0.5kg of phosphorous acid into the reaction system, then raise the temperature to 255°C, and carry out polycondensation reaction at 400Pa for 17.5 hours , then cooled to room temperature, adjusted to normal pressure, precipitated in water, washed the precipitated polymer with ethanol for 5 times, and finally placed in a vacuum drying oven at 85°C to dry to constant weight to obtain a pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com