Antiskid and anti-corrosive high temperature-resistant paint

A high-temperature-resistant coating and corrosion-resistant technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor overall performance and singleness of coatings, and achieve the effect of good corrosion resistance, anti-skid performance, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

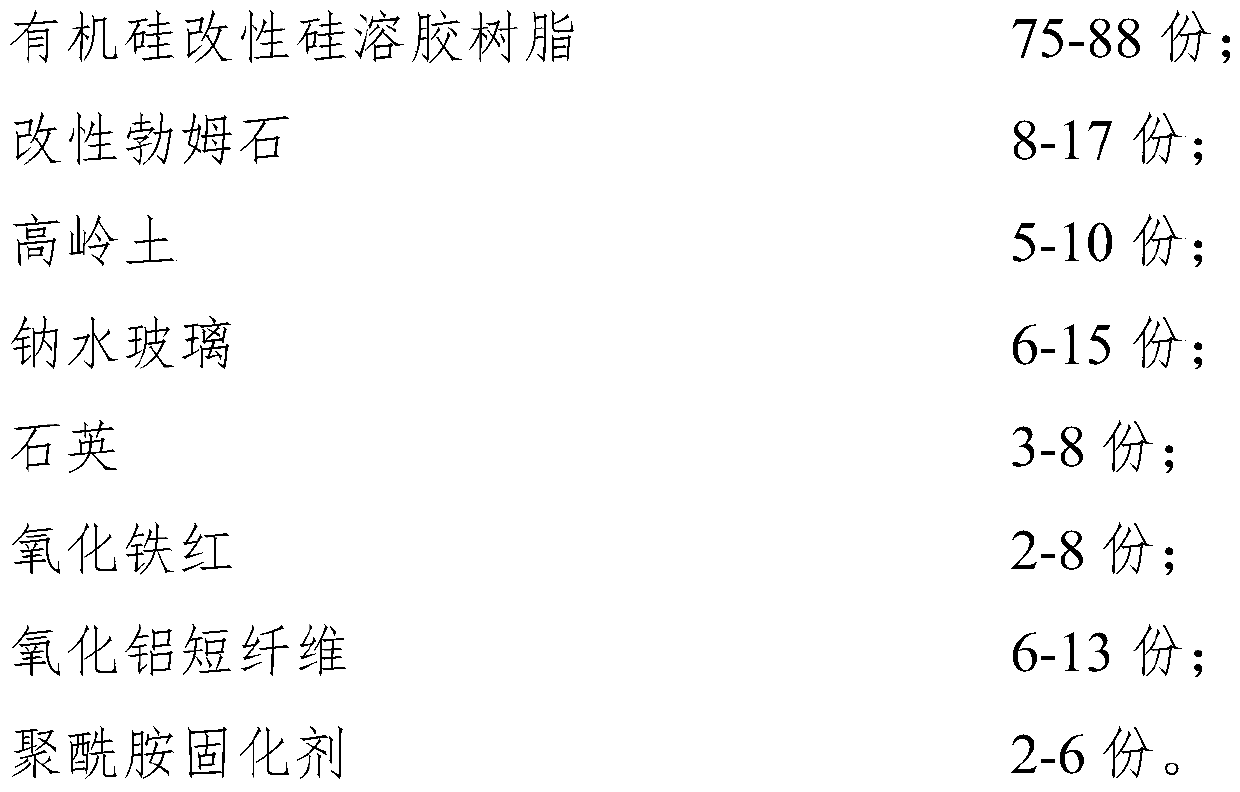

[0031] An anti-skid, corrosion-resistant and high-temperature-resistant paint, the paint raw material includes the following components by weight:

[0032]

[0033] Among them, the preparation method of the silicone-modified silica sol resin solution is: use dilute sulfuric acid to adjust the pH of the alkaline silica sol to 4.0, and mix it with methyltrimethoxysilane and diphenyldimethoxysilane in a mass ratio of 0.5 :1 The mixture composed of alkane is mixed evenly according to the mass ratio of 1:1.2, and poured into a reaction kettle with a reflux device, and the hydrolysis and polycondensation reaction is carried out at a temperature of 70°C, and the reflux reaction is carried out for 6 hours. The reflux device is removed, and the alkaline silica sol is added. Diethylene glycol butyl ether 0.5 times the total mass of the mixture of organosilane, continue to stir, and then heat up to 155 ° C for dehydration, until no water can be detected with anhydrous copper sulfate, s...

Embodiment 2

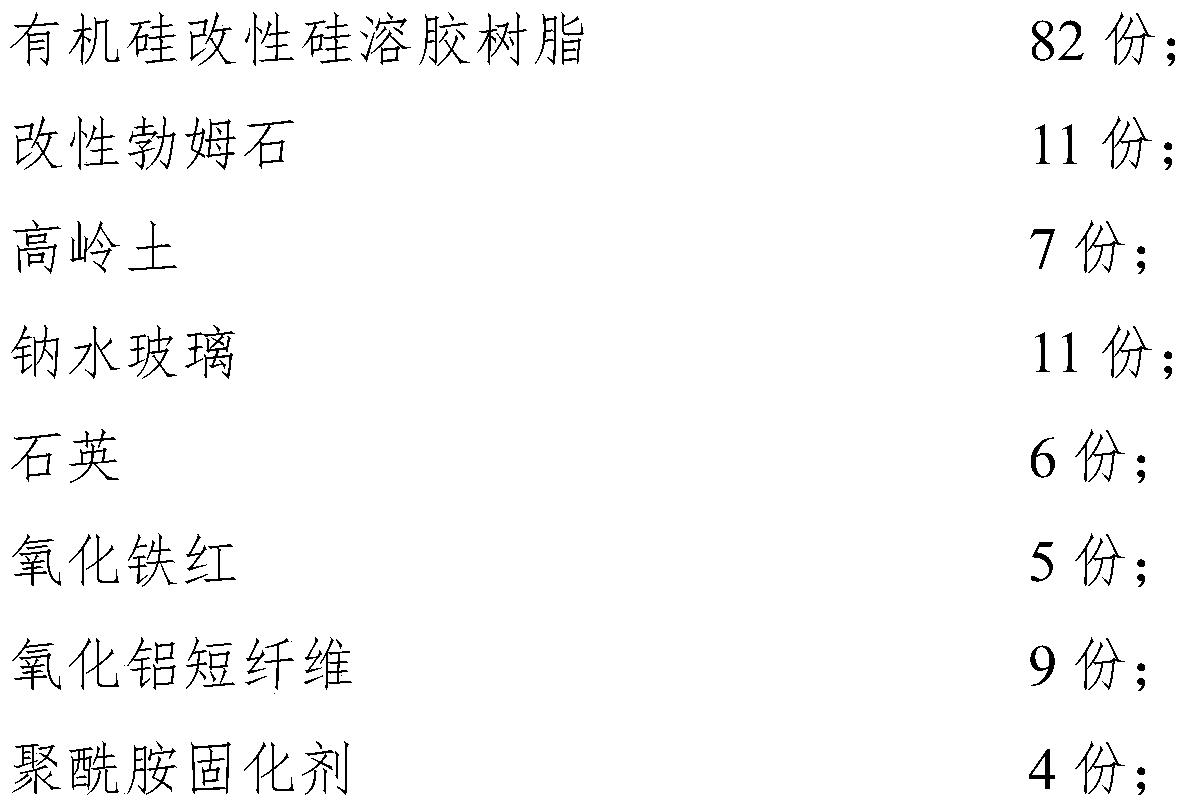

[0040] An anti-skid, corrosion-resistant and high-temperature-resistant paint, the paint raw material includes the following components by weight:

[0041]

[0042] Among them, the preparation method of the silicone-modified silica sol resin solution is: use dilute sulfuric acid to adjust the pH of the alkaline silica sol to 5.5, and mix it with methyltrimethoxysilane and diphenyldimethoxysilane in a mass ratio of 0.4 :1 The mixture composed of alkane is mixed evenly according to the mass ratio of 1:1.1, and poured into a reaction kettle with a reflux device, and the hydrolysis and polycondensation reaction is carried out at a temperature of 66°C, and the reflux reaction is carried out for 6 hours. The reflux device is removed, and the alkaline silica sol is added. Diethylene glycol butyl ether 0.4 times the total mass of the mixture of organosilane, continue to stir, then heat up to 150 ° C for dehydration, until no water can be detected with anhydrous copper sulfate, stop ...

Embodiment 3

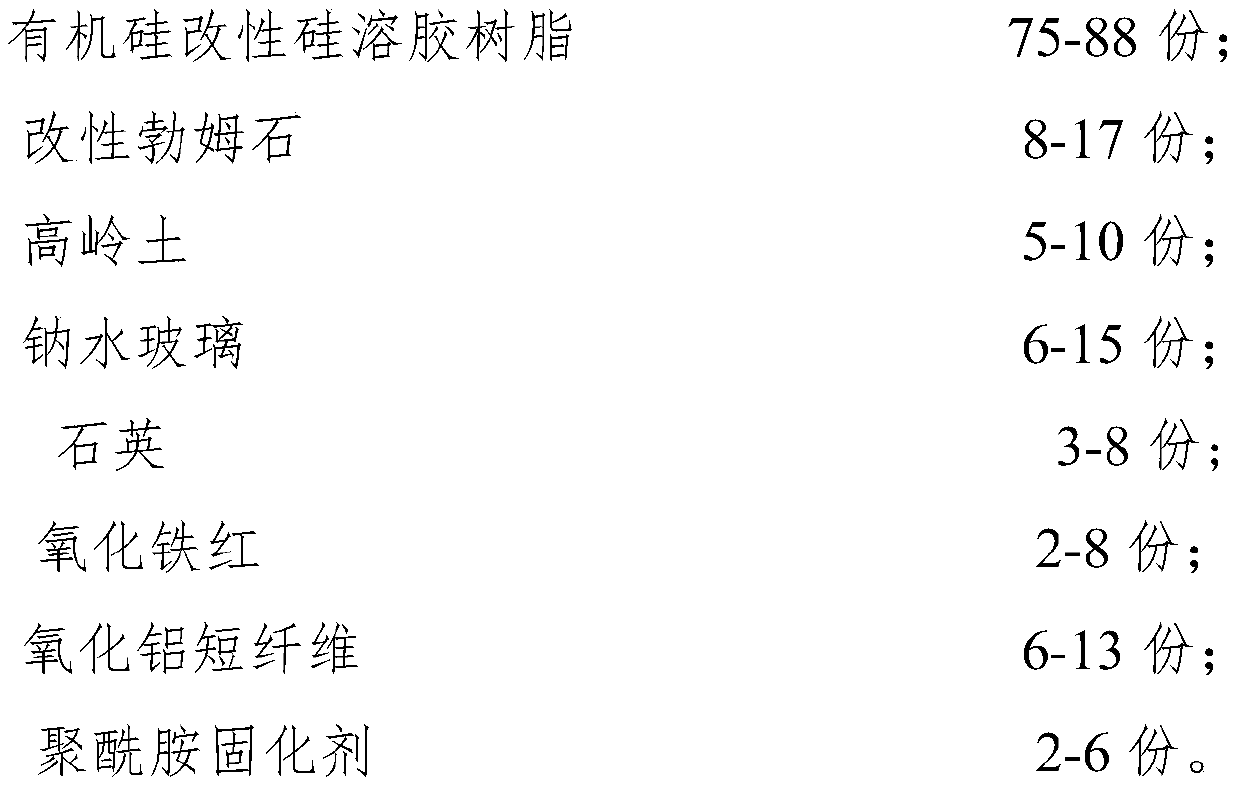

[0049]An anti-skid, corrosion-resistant and high-temperature-resistant paint, the paint raw material includes the following components by weight:

[0050]

[0051] Among them, the preparation method of the silicone-modified silica sol resin solution is: use dilute sulfuric acid to adjust the pH of the alkaline silica sol to 5, and mix it with methyltrimethoxysilane and diphenyldimethoxysilane in a mass ratio of 0.6 :1 The mixture composed of alkane is mixed evenly according to the mass ratio of 1:1.3, and poured into a reaction kettle with a reflux device, and the hydrolysis and polycondensation reaction is carried out at a temperature of 72°C, and the reflux reaction is 7h, the reflux device is removed, and the alkaline silica sol is added Diethylene glycol butyl ether 0.6 times the total mass of the mixture of organosilane, continue to stir, then heat up to 160 ° C for dehydration, until no water can be detected with anhydrous copper sulfate, stop heating, cool to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com