Silicon wafer with silicon oxide film on surface and preparation method

A technology of silicon oxide and thin film, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficult insulating layers, reduce reaction temperature, prevent adverse effects, and expand application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

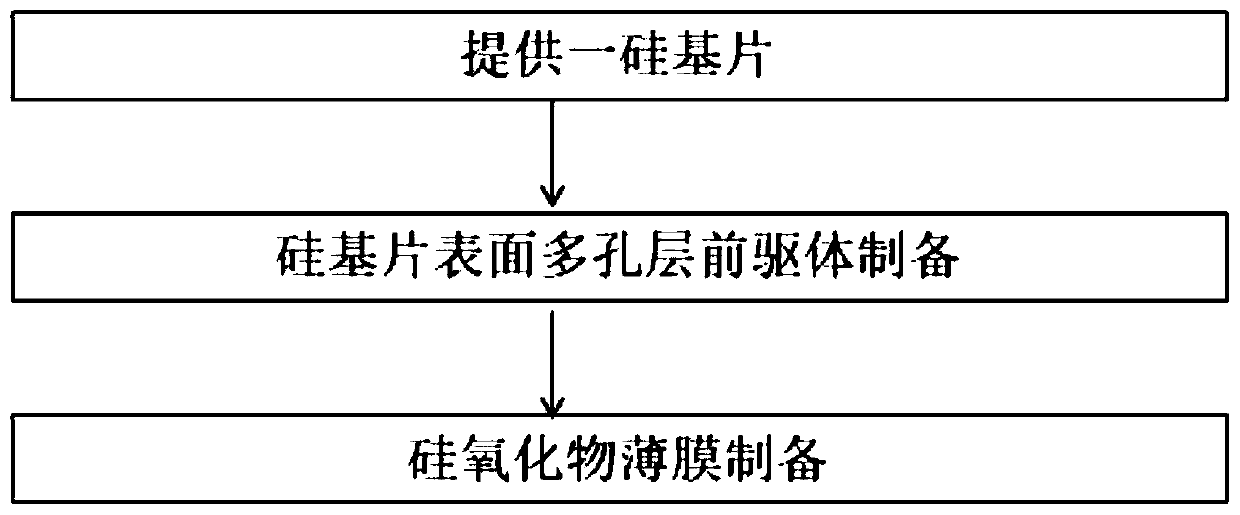

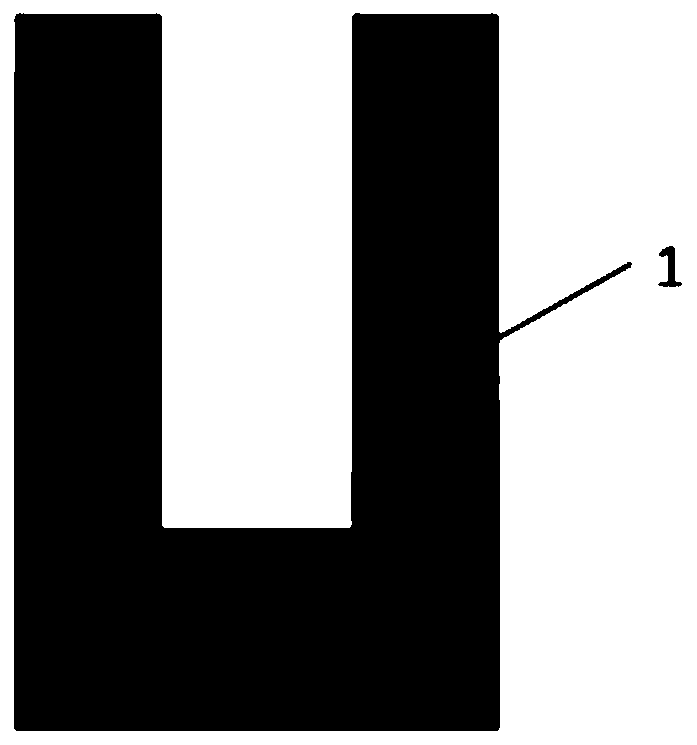

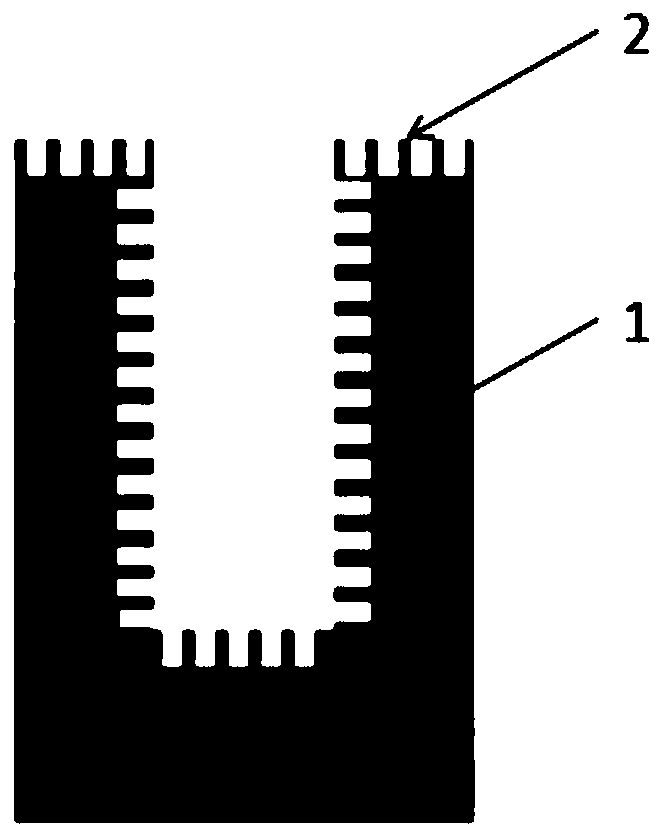

[0044] see figure 1 , Figure 2a to Figure 2c Shown, the invention provides a kind of preparation method of the silicon chip that the surface has silicon oxide thin film, it comprises the steps:

[0045] A1: Provide a silicon substrate 1, the surface of the silicon substrate 1 is provided with vertical blind holes or through holes, and the aspect ratio of the blind holes or through holes is 1:1~1:10;

[0046]A2: Preparation of the precursor of the porous layer on the surface of the silicon substrate: cover the other surface of the silicon substrate that does not need to be etched with polyimide tape, and then place the silicon substrate 1 in the etching solution, The outer surface in contact with the etching solution provides fluoride ions, and at room temperature, the surface of the silicon substrate 1 and the walls of the blind holes are etched by electrolysis to form a porous layer 2. In this embodiment, the composition of the etching solution is Ethanol and fluorine-cont...

Embodiment 2

[0059] This embodiment provides a method for preparing a silicon wafer with a silicon oxide film on the surface. The aspect ratio of the blind hole is selected to be 1:5, and the resistivity is 10. -2 Ω silicon substrate; the specific steps are as follows:

[0060] Step 1: Under the condition of 25°C, use acetone, alcohol and deionized water to ultrasonically clean the silicon wafer for 5 minutes respectively, take it out and dry it for later use;

[0061] Step 2: Prepare an etching solution. In this embodiment, the etching solution is composed of ethanol and a fluorine-containing reagent, wherein the fluorine-containing reagent is preferably a hydrofluoric acid reagent. Add 250 mL of 95% pure absolute ethanol into a polytetrafluoroethylene container, then add 50 mL of 40% hydrofluoric acid solution under magnetic stirring, stir for 20 minutes and let stand to obtain a clear solution.

[0062] Step 3: After the silicon substrate cleaned in step 1 is covered with polyimide tap...

Embodiment 3

[0067] This embodiment provides a method for preparing a silicon wafer with a silicon oxide film on the surface, using a silicon substrate with a blind hole aspect ratio of 1:10 and a resistivity of 20Ω; the specific steps are as follows:

[0068] Step 1: Under the condition of 25°C, use acetone, alcohol and deionized water to ultrasonically clean the silicon wafer for 5 minutes respectively, take it out and dry it for later use;

[0069] Step 2: Prepare an etching solution. In this embodiment, the etching solution is composed of ethanol and a fluorine-containing reagent, wherein the fluorine-containing reagent is preferably a hydrofluoric acid reagent. Add 250 mL of 95% pure absolute ethanol into a polytetrafluoroethylene container, then add 50 mL of 40% hydrofluoric acid solution under magnetic stirring, stir for 20 minutes and let stand to obtain a clear solution.

[0070] Step 3: After the silicon substrate cleaned in step 1 is covered with polyimide tape, the part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com