Method for preparing nano biochar spheres from syrup wastewater

A technology of biochar and nano-carbon balls, applied in nano-carbon, chemical instruments and methods, multi-stage treatment of water/sewage, etc., can solve problems such as failure to meet wastewater discharge standards, consumption of large chemicals and energy, and eutrophication of water bodies. , to save materials, reduce preparation costs, and control the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing nano biochar spheres from syrup wastewater, comprising the following steps:

[0025] S1: Put the syrup waste liquid, sodium lauryl sulfate and ultrapure water in a beaker, stir at 300r / min and 40°C for 30 minutes, and set aside for later use. The syrup waste liquid and dodecane in this example The quality of sodium base sulfate is respectively 10g and 0.05g, wherein the fructose content in the syrup waste liquid is 60wt%, and the consumption of ultrapure water is 10ml / g fructose;

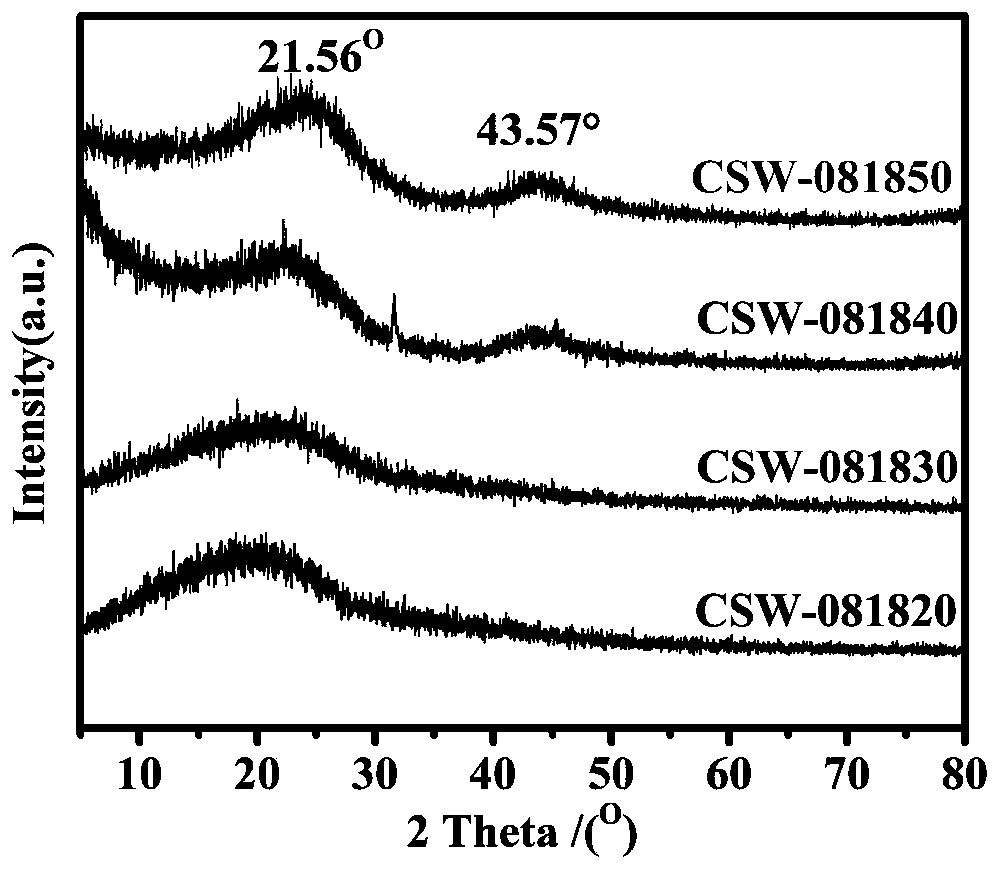

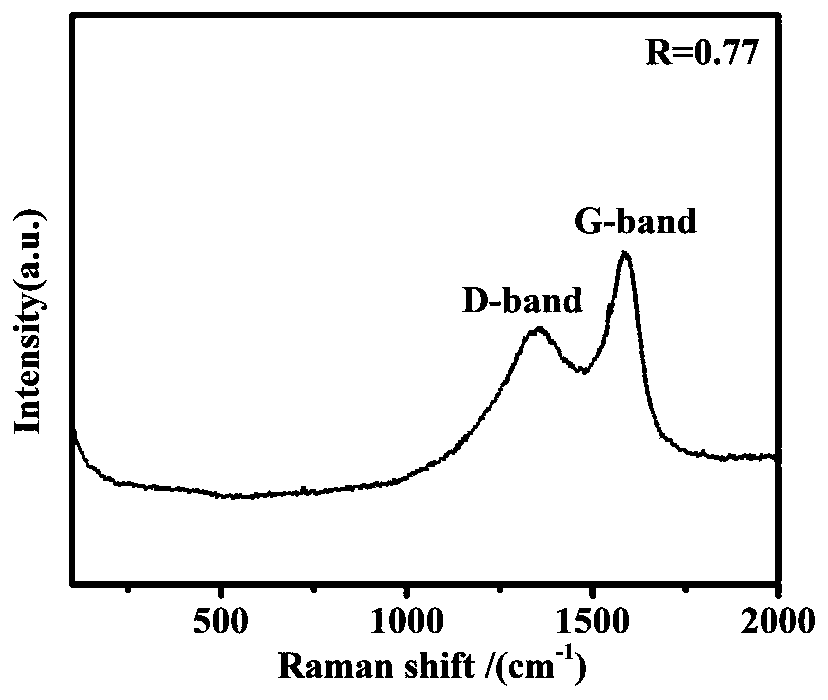

[0026] S2: Transfer the solution treated in step S1 to a 100mL autoclave, react under high pressure at 180-240°C for 2-8h, take it out and cool to room temperature;

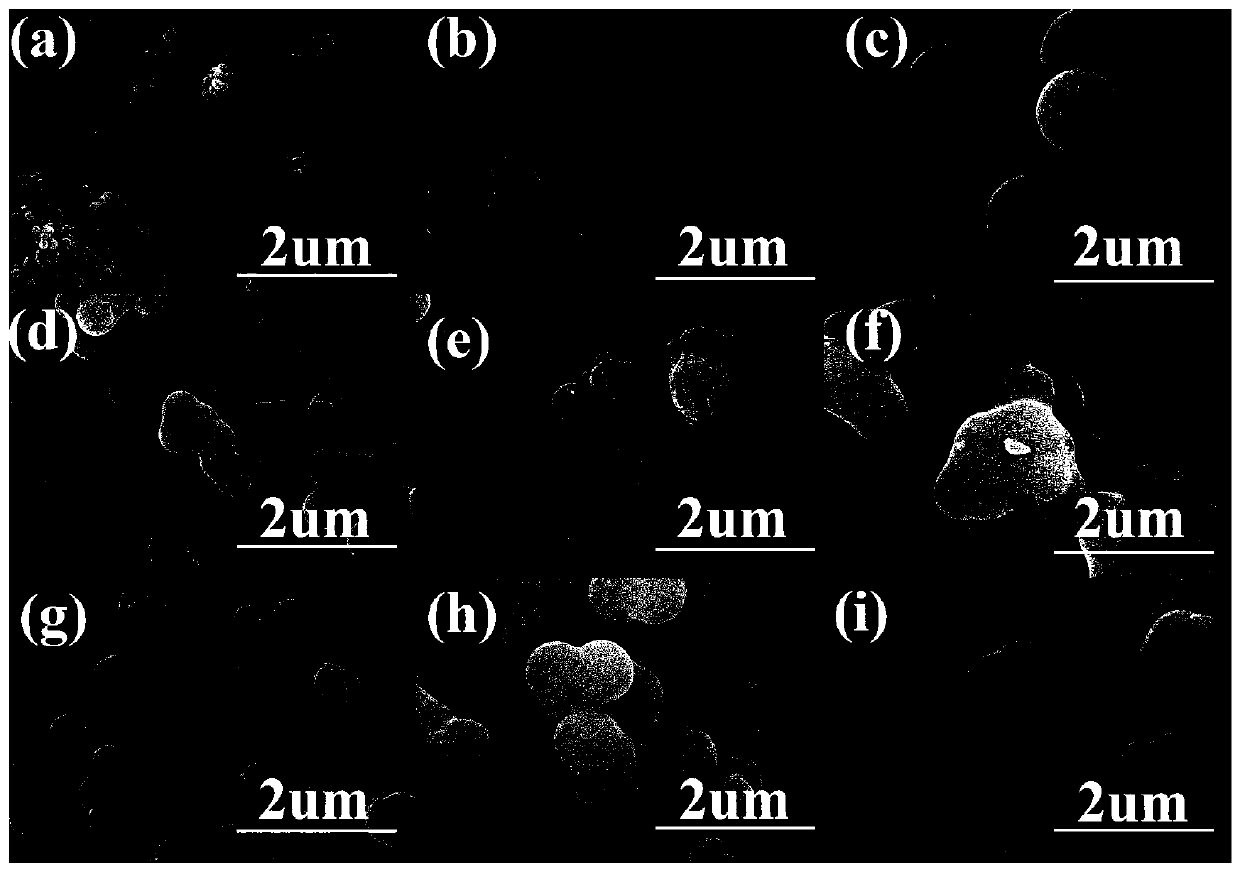

[0027] S3: Suction filter the product treated in step S2 with a 0.22um water-based filter membrane, wash the filtered product with distilled water and absolute ethanol three times, and vacuum-dry it at 80°C for more than 12 hours to prepare carbon nanospheres ;

[0028] S4: In order to further increase t...

Embodiment 2

[0048] A method for preparing nano biochar spheres from syrup wastewater, comprising the following steps:

[0049] S1: Put the syrup waste liquid, sodium lauryl sulfate and ultrapure water in a beaker, stir at 300r / min and 40°C for 30 minutes, and set aside for later use. The fructose, fructose, and The mass ratio of ultrapure water to sodium lauryl sulfate is (100-200): 200:1;

[0050] S2: Transfer the solution treated in step S1 to a 100mL autoclave, react under high pressure at 180-240°C for 2-8h, take it out and cool to room temperature;

[0051] S3: Suction filter the product treated in step S2 with a 0.22um water-based filter membrane, wash the filtered product with distilled water and absolute ethanol three times, and vacuum-dry it at 80°C for more than 12 hours to prepare carbon nanospheres ;

[0052] S4: In order to further increase the number of surface groups and the specific surface area of carbon nanospheres, in this embodiment, the carbon nanospheres prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com