Solvent-resistant and low temperature impact-resistant polycarbonate alloy material and preparation method thereof

A technology of polycarbonate and alloy materials, applied in the field of polycarbonate alloy materials and its preparation, can solve the problems that the improvement effect is limited to xylene, the improvement range is not obvious, and the scope of application is narrow, achieving excellent rigidity-toughness balance performance, Synergistic improvement of chemical resistance and mechanical properties, improving the effect of easy stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

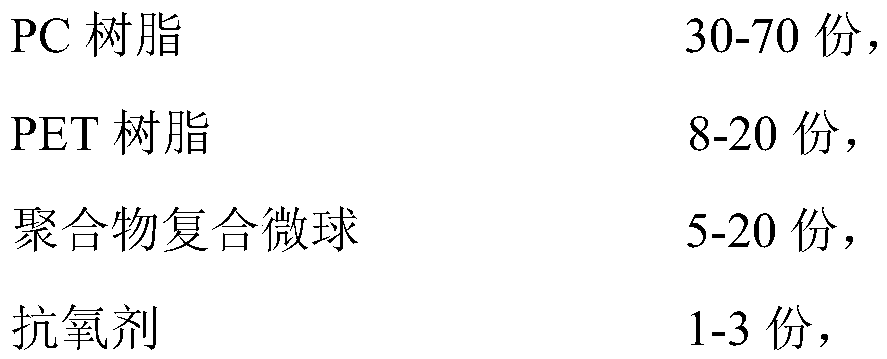

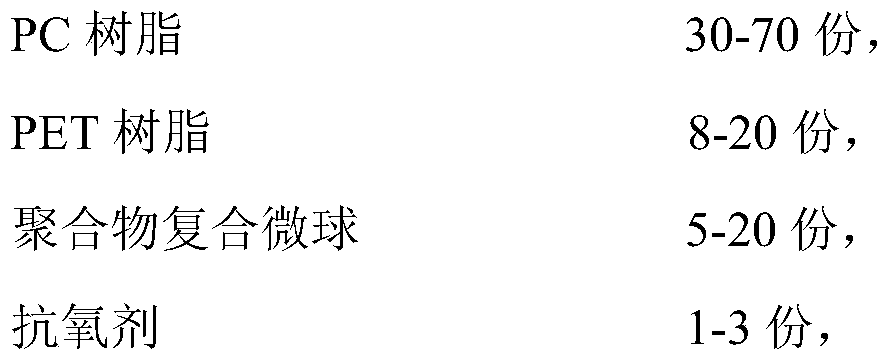

Method used

Image

Examples

Embodiment 1

[0039] According to the data of Example 1 shown in Table 1, weigh and take fluorine-containing acrylate monomer, maleic anhydride monomer, and surfactant in a certain proportion, and prepare an emulsified solution with a concentration of 1:10 to 1:30 with water , add a high-efficiency surfactant under high-speed stirring to form a relatively stable monomer emulsion, then raise the temperature to 65°C, reduce the stirring speed and add azotized fullerene powder at the same time to initiate anionic emulsion polymerization of the monomer, and the reaction After the end, the moisture contained therein is removed by repeated rotary evaporation treatment, so as to obtain organic-inorganic hybrid polymer composite microspheres.

[0040] Formulation table (unit: gram) of polymer composite microsphere of table 1

[0041] Example 1 Example 2 Example 3 Example 4 Example 5 Fluorinated acrylate copolymer 6 3 10 6 8 Fullerene C60 powder 2 7 1 5 4 ...

Embodiment 2

[0043] According to the data of Example 2 shown in Table 1, weigh and take fluorine-containing acrylate monomers, maleic anhydride monomers, and surfactants in a certain proportion, and prepare them with water to form an emulsified solution with a concentration of 1:10 to 1:30 , add a high-efficiency surfactant under high-speed stirring to form a relatively stable monomer emulsion, then raise the temperature to 65°C, reduce the stirring speed and add azotized fullerene powder at the same time to initiate anionic emulsion polymerization of the monomer, and the reaction After the end, the moisture contained therein is removed by repeated rotary evaporation treatment, so as to obtain organic-inorganic hybrid polymer composite microspheres.

Embodiment 3

[0045] According to the data of Example 1 shown in Table 1, weigh and take fluorine-containing acrylate monomer, maleic anhydride monomer, and surfactant in a certain proportion, and prepare an emulsified solution with a concentration of 1:10 to 1:30 with water , add a high-efficiency surfactant under high-speed stirring to form a relatively stable monomer emulsion, then raise the temperature to 65°C, reduce the stirring speed and add azotized fullerene powder at the same time to initiate anionic emulsion polymerization of the monomer, and the reaction After the end, the moisture contained therein is removed by repeated rotary evaporation treatment, so as to obtain organic-inorganic hybrid polymer composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com