Lithium vanadium fluorophosphate-lithium vanadyl phosphate composite positive electrode material, preparation method and application thereof

A composite positive electrode material, lithium vanadyl phosphate technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of reducing the use of raw material fluorine salts and high production costs, and achieve the difficulty of simplifying the calcination process and comprehensive production The effect of low cost and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment discloses a preparation method of lithium vanadium phosphate-lithium vanadyl phosphate, a composite cathode material for a lithium ion battery, comprising the following steps:

[0028] Lithium carbonate, vanadium pentoxide, ammonium dihydrogen phosphate and lithium fluoride are mixed at a molar ratio of Li:V:P:F=1.15:1.15:1.15:1 to prepare composite material component 0.15LiVOPO 4 ·LiVPO 4 F, then add tributyl borate of 3% of the total mass of the mixture and 30% glucose and 10% citric acid by mass fraction, then add a dispersant for high-energy ball milling, vacuum dry at 120°C, compress the pre-calcined precursor and place it in the The sintering treatment was carried out under air atmosphere, the sintering temperature was 650°C, the holding time was 3h, and the lithium vanadium phosphate-lithium vanadyl phosphate composite positive electrode material was obtained after natural cooling.

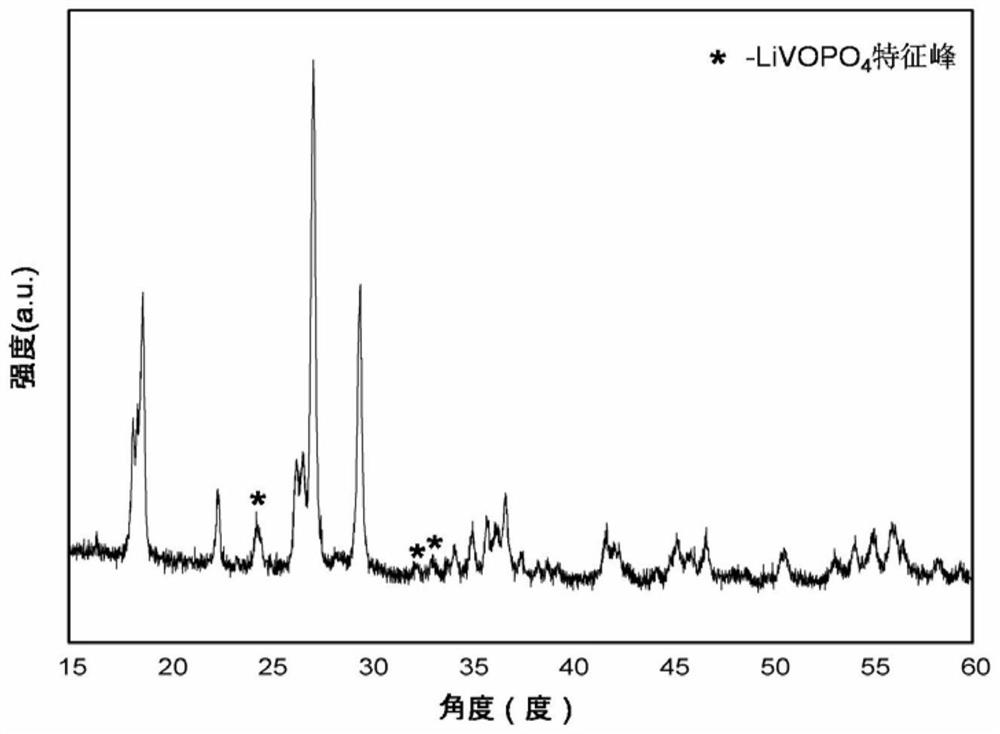

[0029] From the XRD spectrum (such as figure 1 Shown) Analysis...

Embodiment 2

[0032] This embodiment discloses a preparation method of lithium vanadium phosphate-lithium vanadyl phosphate, a composite cathode material for a lithium ion battery, comprising the following steps:

[0033] Lithium carbonate, vanadium phosphate and lithium fluoride are mixed at a molar ratio Li:V:P:F=1.15:1.15:1 to prepare composite material component 0.30LiVOPO 4 ·LiVPO 4 F, then adding tributyl borate and mass fraction of 7% of the total mass of the mixture are 20% glucose and 5% graphene conductive paste (5% ethanol system by mass fraction), followed by adding dispersant and carrying out high-energy ball milling, vacuum at 120°C After drying, the pre-calcined body was pressed into tablets, and then placed in an air atmosphere for sintering treatment. The sintering temperature was 550 ° C, and the holding time was 3 hours. After natural cooling, the lithium vanadium phosphate-lithium vanadyl phosphate composite positive electrode material was obtained.

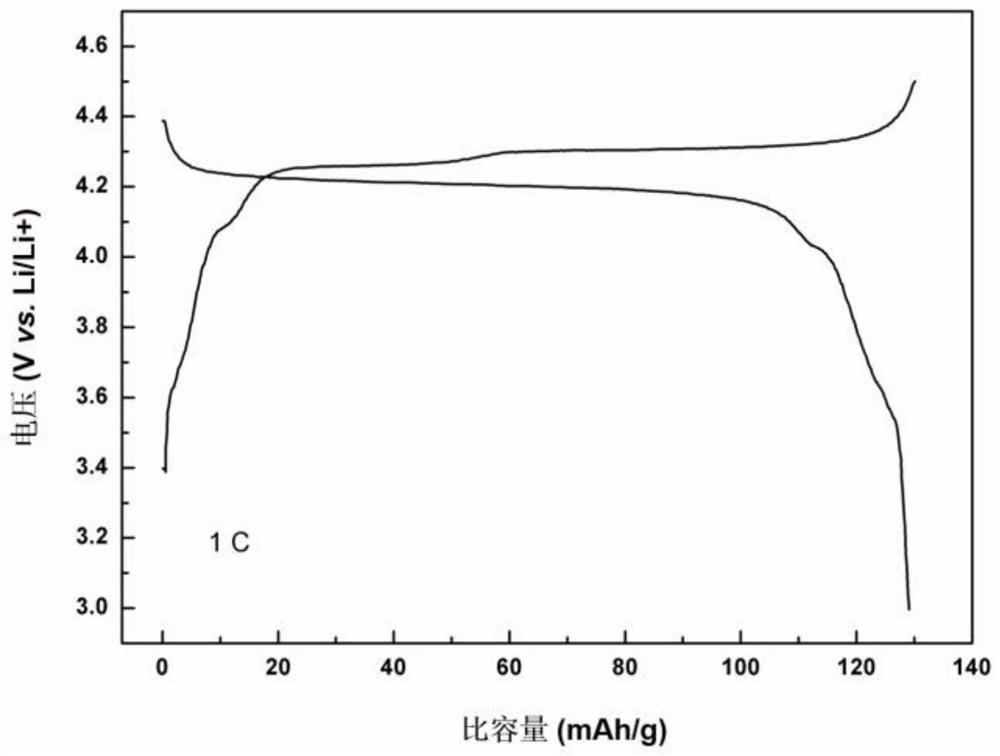

[0034] A lithium-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com