A modified cathode material, its preparation method and lithium ion battery

A positive electrode material and modification technology, applied in positive electrodes, battery electrodes, secondary batteries, etc., can solve problems such as restricting the development of lithium-ion batteries and reducing the cycle life of lithium-ion batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention discloses a preparation method of a modified positive electrode material, comprising the following steps;

[0028] Step S1: forming a vanadium disulfide coating layer on the surface of the positive electrode material;

[0029] Step S2: Grinding and mixing the positive electrode material with a vanadium disulfide coating layer on the surface and the lithium source evenly, and calcining in an oxygen atmosphere to obtain an intermediate product;

[0030] Step S3: The intermediate product is mixed with a fluorine source and then further calcined to obtain a modified positive electrode material.

[0031] The preparation method of the modified positive electrode material is described in detail in accordance with the steps below:

[0032] Step S1: forming a vanadium disulfide coating layer on the surface of the positive electrode material.

[0033] Specifically:

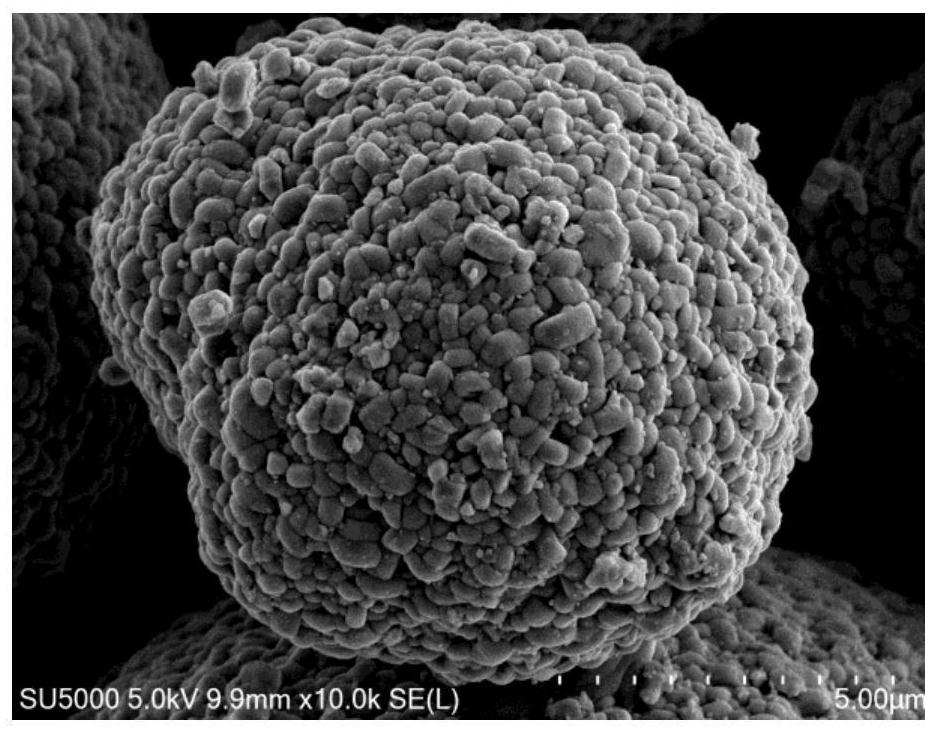

[0034] The positive electrode material, the precursor solution of the s...

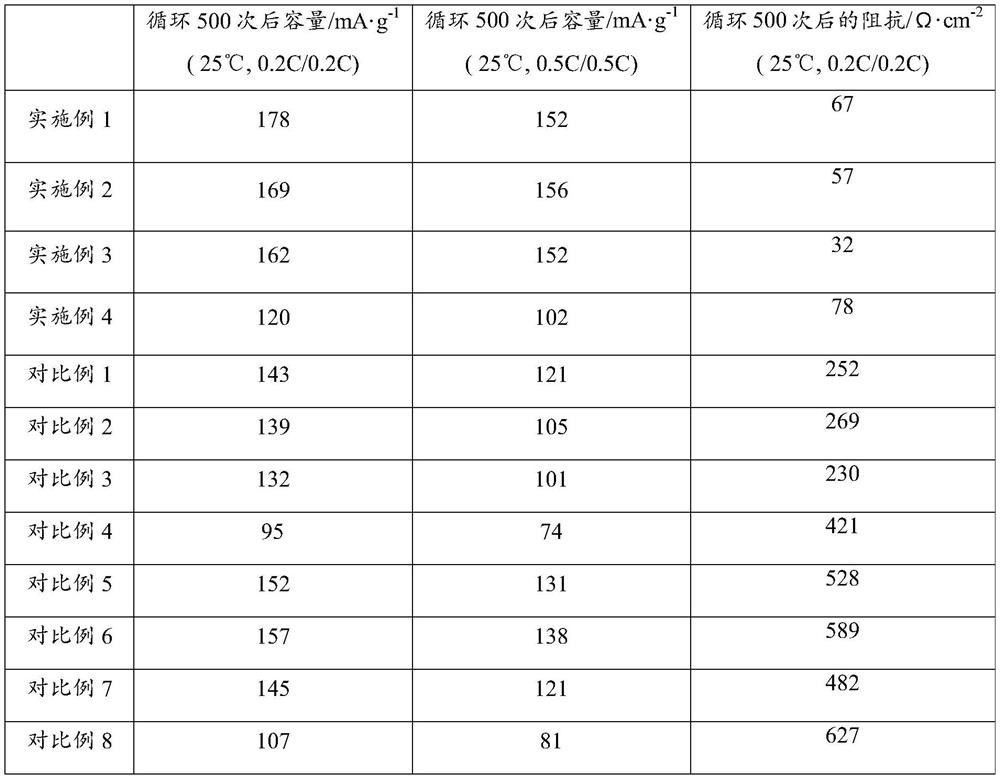

Embodiment 1

[0050] (1) Put 5g of nickel-cobalt lithium aluminate in a homogeneous mixed solution of precursors of 5mg / ml thioacetamide and 8mg / ml ammonium metavanadate, at 180°C, hydrothermally react for 12h to form a layer of VS 2 cladding;

[0051] (2) The surface is grown with VS 2 The coating layer of lithium nickel cobalt aluminate and 1.5 times the mole of lithium carbonate are uniformly ground, and then placed in an oxygen atmosphere at 800 ° C for 12 hours at a high temperature to form Li 3 VO 4 cladding;

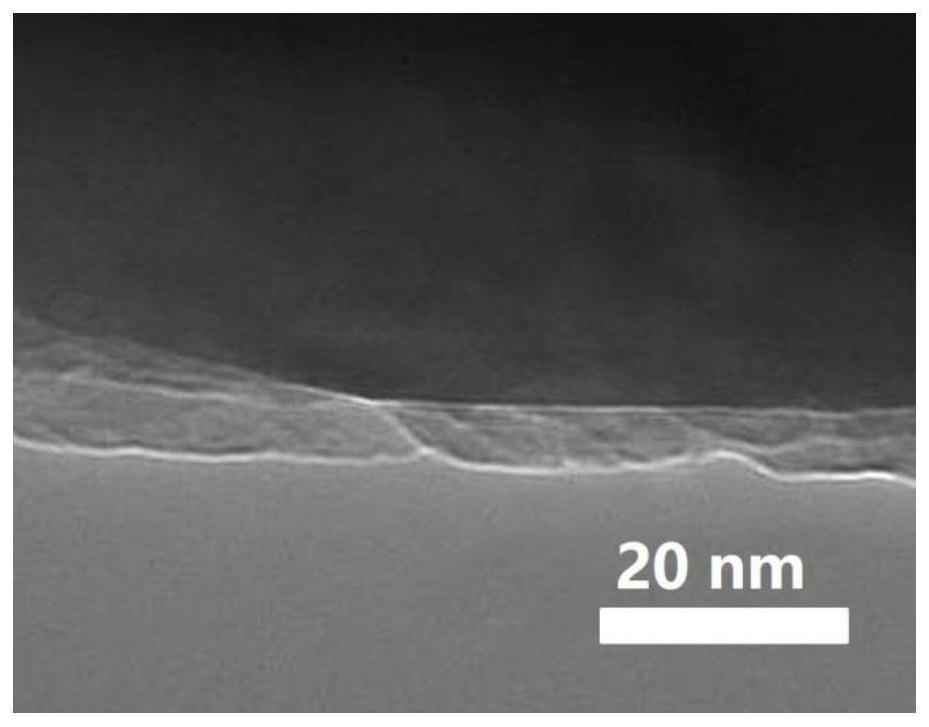

[0052] (3) will form Li 3 VO 4 The nickel-cobalt-lithium aluminate and 0.1% lithium fluoride in the coating layer are uniformly ground and then placed in a high-temperature tube furnace at 300°C for 12 hours to obtain the modified positive electrode material. In the modified positive electrode material, lithium orthovanadate is coated on the surface of the nickel-cobalt-aluminate lithium, and fluorine is doped in the nickel-cobalt-aluminate lithium and in the surface coati...

Embodiment 2

[0054] (1) 5g lithium nickel cobalt manganese oxide LiN i0.6 co 0.2 mn 0.2 o 2 Place in a homogeneous precursor solution of 10mg / ml thiourea and 8mg / ml ammonium metavanadate, 180°C, hydrothermal reaction for 12h to form a layer of VS 2 cladding;

[0055] (2) The surface is grown with VS 2 Coating layer nickel cobalt lithium manganese oxide and 2 times the mole of lithium acetate are evenly ground and placed in an oxygen atmosphere at 1000°C for 24 hours at high temperature to form Li 3 VO 4 cladding;

[0056] (3) will form Li 3 VO 4 The nickel-cobalt-lithium manganese oxide and 0.5% ammonium fluoride in the coating layer are uniformly ground and calcined in a high-temperature tube furnace at 500°C for 12 hours to obtain the modified positive electrode material. In the modified positive electrode material, lithium orthovanadate is coated on the surface of lithium nickel cobalt manganese oxide, and fluorine is doped in the lithium nickel cobalt manganese oxide and in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com