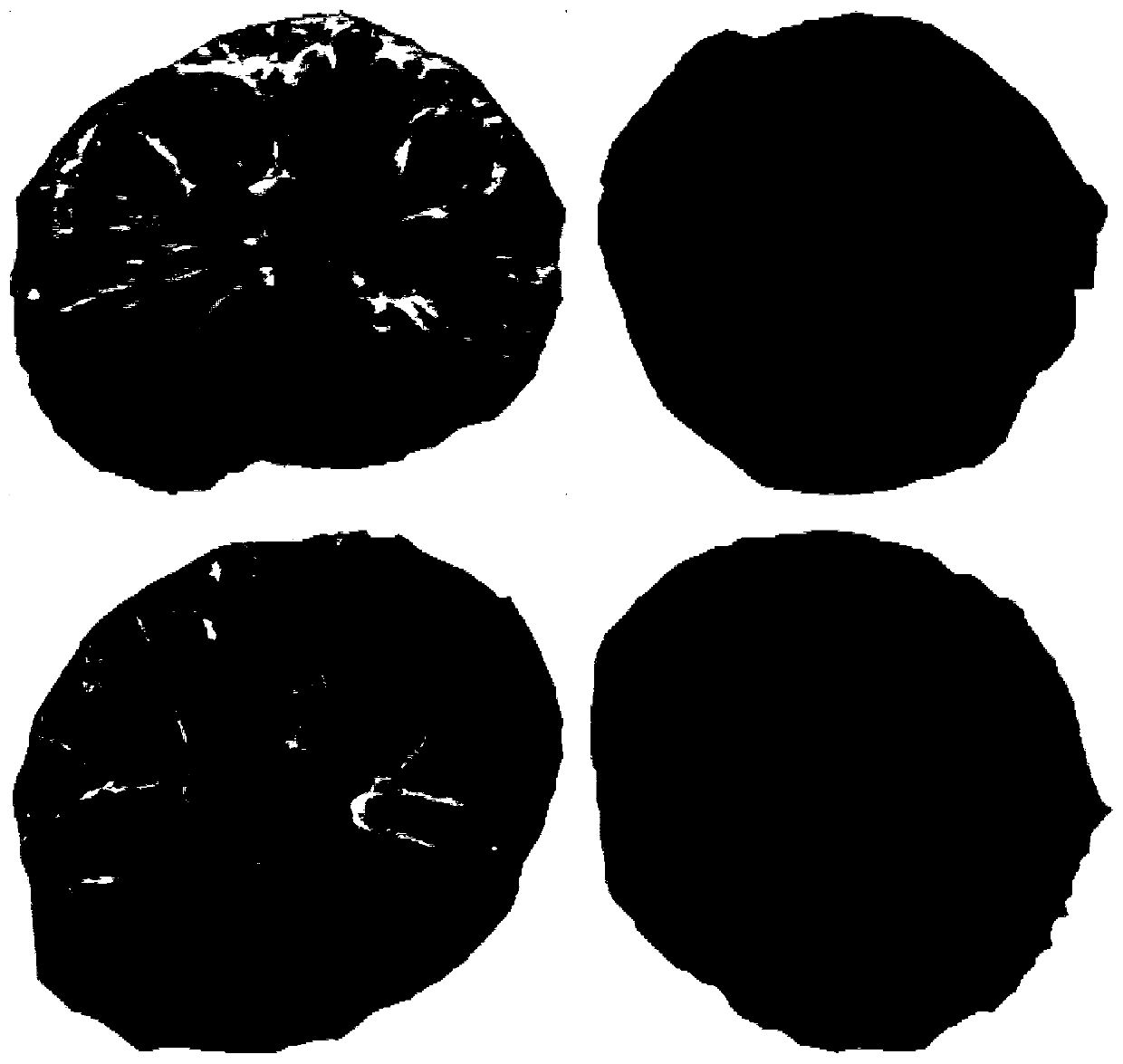

Preparation method of nanofiber micro-moisture oil-water separation material with porous surface and lotus-root-shaped cross section

A surface porous, nanofiber technology, applied in separation methods, immiscible liquid separation, liquid separation, etc., can solve the problems of poor separation efficiency, secondary pollution, unenvironmental protection, etc., achieve high porosity, small pore size, high The effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This implementation case shows a preparation method of a nanofiber micro-moisture oil-water separation material with a porous surface and a lotus-shaped cross-section according to the following steps. The specific steps are as follows:

[0035] (1) Prepare the shell PLA spinning solution: dissolving the PLA particles in a mixed solvent of DCM and DMAC with a mass ratio of 10:1 to obtain a shell PLA solution with a concentration of 8wt%;

[0036] (2) Preparation of nuclear layer PVA spinning solution: PVA particles are dissolved in DMSO solvent, after the PVA particles are completely dissolved, then DCM (wherein DMSO / DCM solvent ratio 2:1) is added in the PVA / DMSO mixed solution, finally Obtain 2wt% nuclear layer PVA solution;

[0037] (3) Coaxial electrospinning: Coaxial electrospinning with aluminum foil as the receiving base material produces nanofiber micro-moisture oil-water separation materials with a porous surface and a lotus-shaped cross-section. The process par...

Embodiment 2

[0041] This implementation case shows a preparation method of a nanofiber micro-moisture oil-water separation material with a porous surface and a lotus-shaped cross-section according to the following steps. The specific steps are as follows:

[0042] (1) Preparation of shell PLA spinning solution: with step (1) in Example 1;

[0043] (2) prepare nuclear layer PVA spinning solution: with step (2) among the embodiment 1;

[0044](3) Coaxial electrospinning: Coaxial electrospinning with aluminum foil as the receiving base material makes nanofiber micro-moisture oil-water separation materials with porous surface and lotus-shaped cross-section. The process parameters of electrospinning are: spinning temperature 25 ℃, the flow rate of the inner and outer layers of the spinning solution is 0.3mL / h: 0.9mL / h, the spinning voltage is 19kV, and the receiving distance is 9cm. The receiving device of electrospinning is a horizontal moving drum, the receiving substrate is covered on the d...

Embodiment 3

[0048] This implementation case shows a preparation method of a nanofiber micro-moisture oil-water separation material with a porous surface and a lotus-shaped cross-section according to the following steps. The specific steps are as follows:

[0049] (1) Preparation of shell PLA spinning solution: with step (1) in Example 1;

[0050] (2) prepare nuclear layer PVA spinning solution: with step (2) among the embodiment 1;

[0051] (3) Coaxial electrospinning: Coaxial electrospinning with aluminum foil as the receiving base material produces a nanofiber micro-moisture oil-water separation material with a porous surface and a lotus-shaped cross-section. The process parameters of the electrospinning are: spinning temperature 22 ℃, the flow rate of the inner and outer layers of the spinning solution is 0.3mL / h: 0.9mL / h, the spinning voltage is 19kV, and the receiving distance is 12cm. The receiving device of electrospinning is a horizontal moving drum, the receiving substrate is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com