Macromolecular fluorescent beautifying colloid film for automobile, and preparation process and production equipment thereof

A colloidal film and production equipment technology, which is applied in the field of automotive materials, can solve the problems of poor equipment matching, cumbersome preparation process, and difficulty in large-scale promotion, and achieve enhanced beautification and decoration effects, simplified preparation process, and good fluorescence and beautification effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The polymer fluorescent beautifying colloid film for automobiles provided in this embodiment is made of the following components in parts by weight: 50-100 parts of vinyl chloride-butyl acrylate copolymer, 3-6 parts of rare earth polymer fluorescent material, formazan 20-30 parts of base hydrogen-containing silicone resin, 15-40 parts of PVC resin, 7-10 parts of nitrile rubber, 5-7 parts of isobutyl rubber, 1215 parts of nano-metal flash powder, 3-8 parts of flame retardant, 15-20 parts of plasticizer, 3-6 parts of stabilizer, 0.4-0.7 parts of accelerator, 8-30 parts of impact modifier, 10-12 parts of weather resistance modifier; 0.01-0.05 parts of inorganic pigment; 5-8 parts of silicon oxide, the thickness of the film is 1-5mm. The rare earth polymer fluorescent material is an acrylic rare earth polymer fluorescent material.

[0039] Specifically, in this embodiment, the polymer fluorescent beautifying colloidal film for automobiles is made of the following component...

Embodiment 2

[0056] The polymer fluorescent beautifying colloidal film for automobiles, preparation method and production equipment provided in this embodiment are basically the same as in Example 1, except that:

[0057] The polymer fluorescent beautifying colloidal film for automobiles is made of the following components in parts by weight: 90 parts of vinyl chloride-butyl acrylate copolymer, 25 parts of methyl hydrogen-containing silicone resin, 40 parts of PVC resin, nitrile rubber 9 parts, 6 parts of isobutylene rubber, 14 parts of nano metal glitter powder, 7 parts of flame retardant, 18 parts of plasticizer, 5 parts of stabilizer, 0.67 parts of accelerator, 28 parts of impact modifier, weather resistance modifier 11 parts of neutralizing agent, 5 parts of rare earth polymer fluorescent material, 0.045 parts of inorganic pigment; 5 parts of nano silicon dioxide; film thickness is 1-2mm.

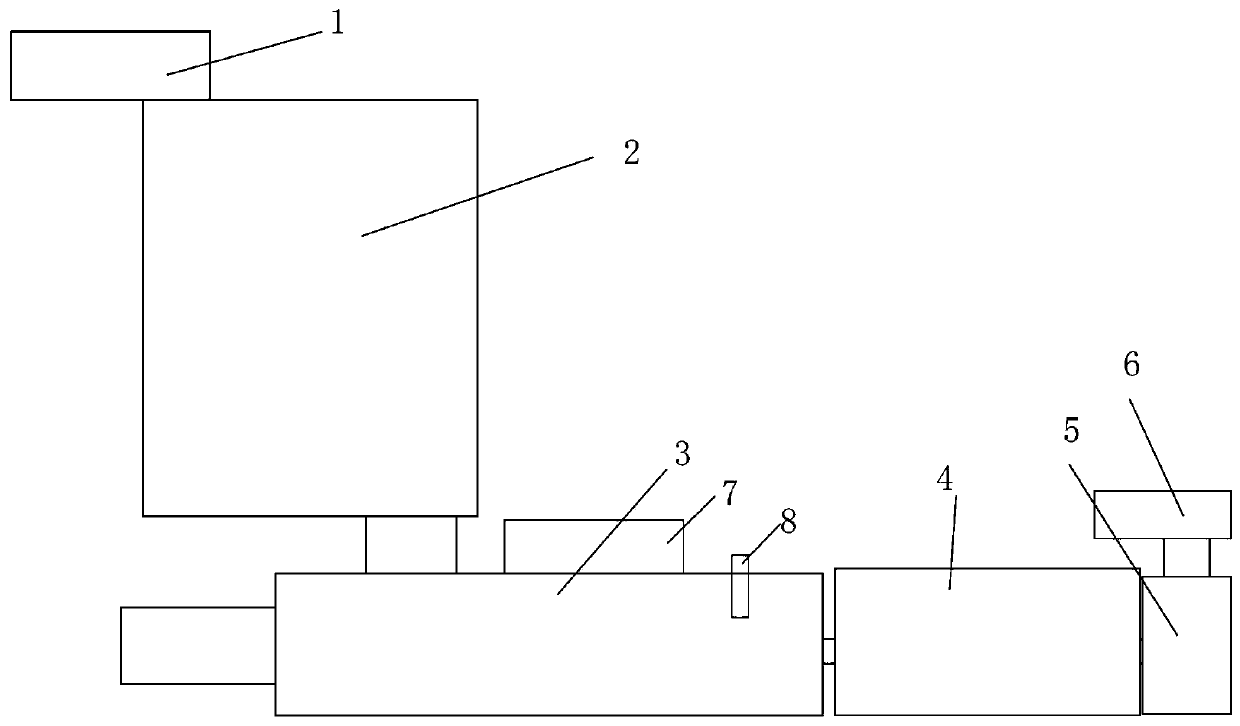

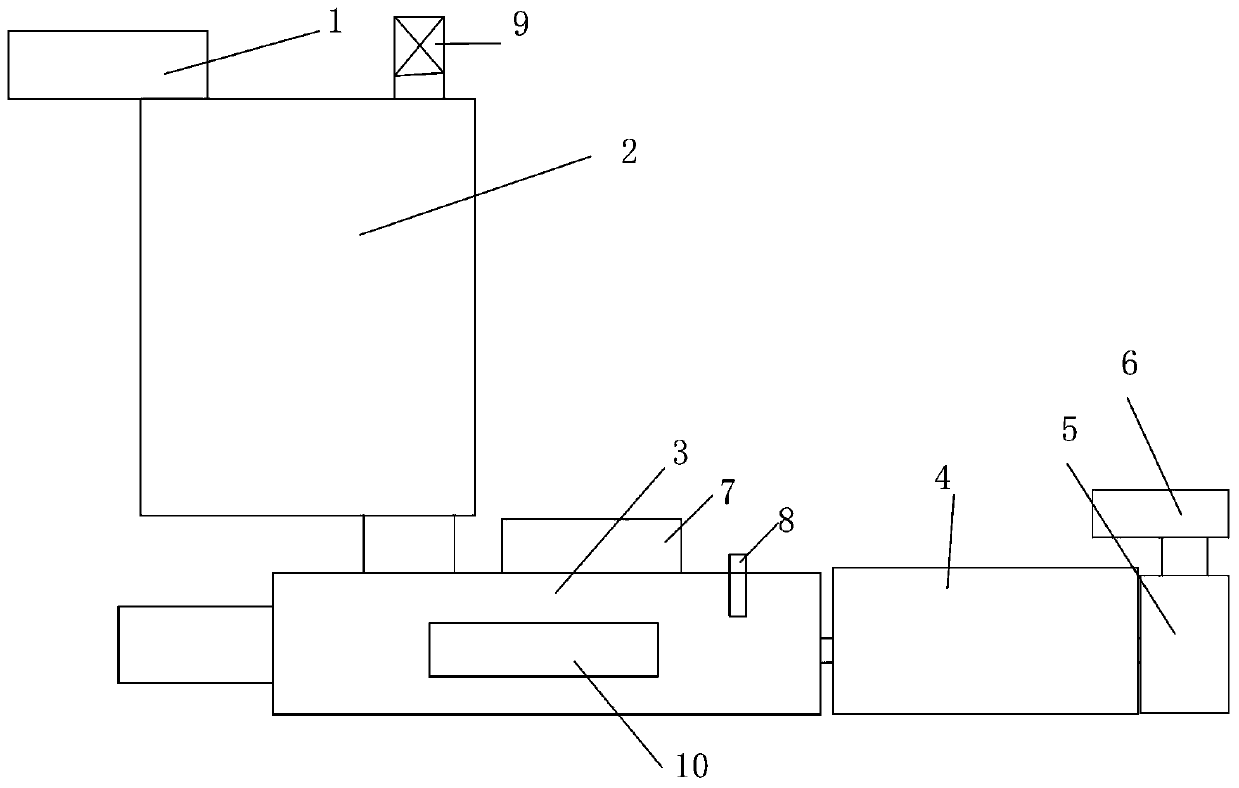

[0058] see figure 2 , The production equipment of the polymer fluorescent beautifying colloida...

Embodiment 3

[0061] The polymer fluorescent beautifying colloidal film for automobiles, preparation method and production equipment provided in this embodiment are basically the same as those in Examples 1 and 2, except that:

[0062] The polymer fluorescent beautifying colloidal film for automobiles is made of the following components in parts by weight: 100 parts of vinyl chloride-butyl acrylate copolymer, 30 parts of methyl hydrogen-containing silicone resin, 40 parts of PVC resin, and 10 parts of nitrile rubber. 7 parts, 7 parts of isobutylene rubber, 15 parts of nano metal glitter powder, 8 parts of flame retardant, 20 parts of plasticizer, 6 parts of stabilizer, 0.7 parts of accelerator, 30 parts of impact modifier, weather resistance modification 12 parts of agent, 6 parts of rare earth polymer fluorescent material, and 8 parts of nano silicon dioxide; the thickness of the film is 4-5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com