Corrosion-resistant high-temperature-resistant PVC-C pipe and preparation method thereof

A technology of PVC-C and high temperature resistance, applied in the field of corrosion-resistant and high-temperature-resistant PVC-C pipes and their preparation, can solve problems such as poor corrosion resistance of chlorinated polyvinyl chloride plastics, and achieve improved processing and molding effects and corrosion resistance. The effect of strong performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

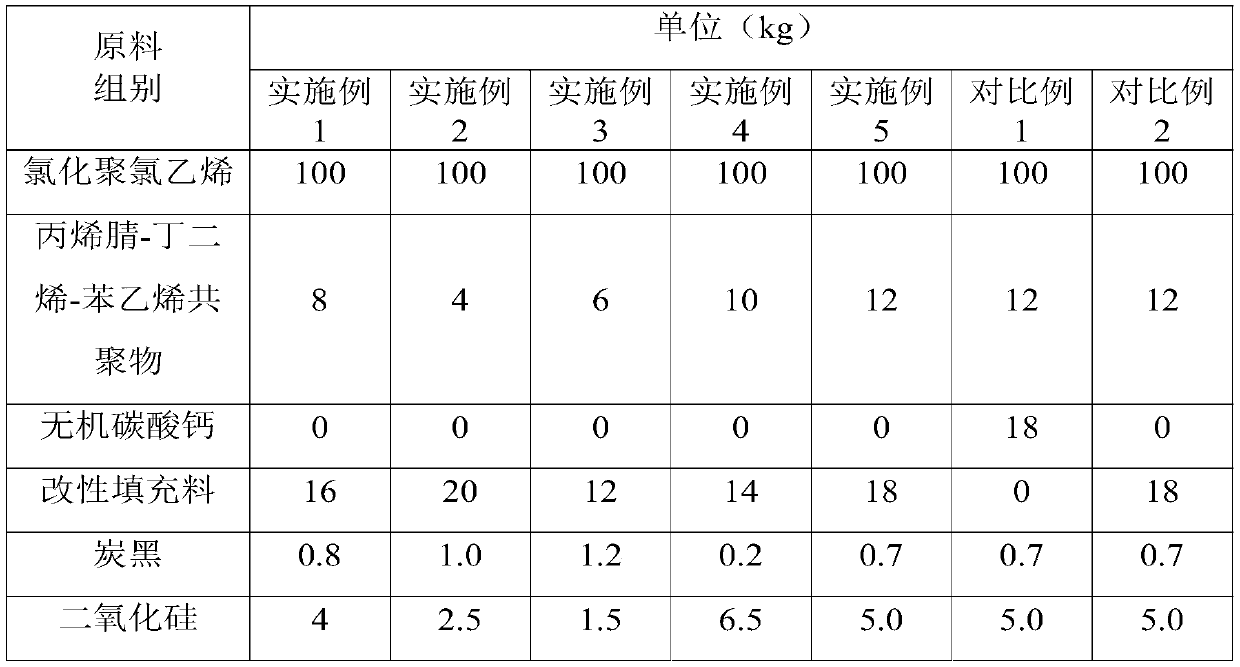

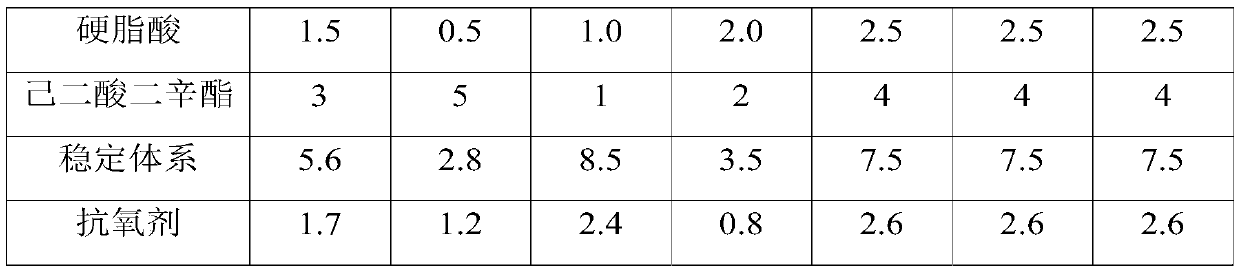

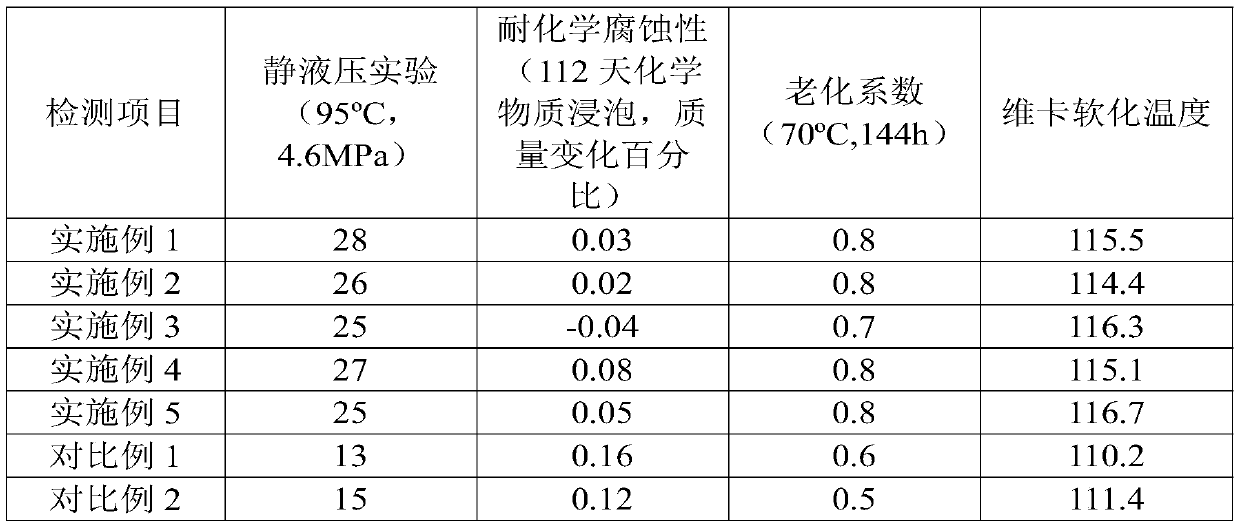

Examples

Embodiment 1

[0034] A corrosion-resistant and high-temperature resistant PVC-C pipe, prepared by the following method:

[0035] Step S10, weighing the raw materials for preparing corrosion-resistant and high-temperature resistant PVC-C pipes according to the above weight parts, wherein the antioxidant is triisodecyl phosphite mixed with antioxidant 300 at a weight ratio of 1:5, and the stabilizing system is castor Calcium sesoleate / zinc laurate stabilizer, organotin stabilizer, and epoxy soybean oil are mixed in a weight ratio of 1:1.5:1.2;

[0036] Step S20, adding the chlorinated polyvinyl chloride, the stabilizing system, acrylonitrile-butadiene-styrene copolymer, carbon black and silicon dioxide in the above parts by weight into a high-speed mixer, and mixing at a speed of 1200 rpm 30 minutes, obtain the premix;

[0037] Step S30, add the above-mentioned weight portion of dioctyl adipate, modified filler, antioxidant and stearic acid to the premix obtained in step S20, continue mixing...

Embodiment 2

[0043] A corrosion-resistant and high-temperature resistant PVC-C pipe, prepared by the following method:

[0044] Step S10, weighing the raw materials for preparing corrosion-resistant and high-temperature resistant PVC-C pipes according to the above weight parts, wherein the antioxidant in the raw materials is triisodecyl phosphite and antioxidant 300 mixed in a weight ratio of 1:2 to stabilize the system Calcium ricinoleate / zinc laurate stabilizer, organotin stabilizer, and epoxy soybean oil are mixed in a weight ratio of 1:0.5:1.2;

[0045] Step S20, adding the chlorinated polyvinyl chloride, stabilizing system, acrylonitrile-butadiene-styrene copolymer, carbon black and silicon dioxide in the above parts by weight into a high-speed mixer, and mixing at a speed of 1300 rpm 20 minutes to obtain the premix;

[0046]Step S30, add the above-mentioned weight portion of dioctyl adipate, modified filler, antioxidant and stearic acid to the premix obtained in step S20, continue m...

Embodiment 3

[0052] A corrosion-resistant and high-temperature resistant PVC-C pipe, prepared by the following method:

[0053] Step S10, weighing the raw materials for preparing corrosion-resistant and high-temperature resistant PVC-C pipes according to the above weight parts, wherein the antioxidant in the raw materials is triisodecyl phosphite and antioxidant 300 mixed in a weight ratio of 1:8 to stabilize the system Calcium ricinoleate / zinc laurate stabilizer, organotin stabilizer, and epoxy soybean oil are mixed in a weight ratio of 1:2.5:1.2;

[0054] Step S20, adding the chlorinated polyvinyl chloride, stabilizing system, acrylonitrile-butadiene-styrene copolymer, carbon black and silicon dioxide in the above parts by weight into a high-speed mixer, and mixing at a speed of 1000 rpm 20 minutes to 30 minutes to obtain the premix;

[0055] Step S30, add the above-mentioned weight portion of dioctyl adipate, modified filler, antioxidant and stearic acid to the premix obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com