Humidity sensor, preparation method thereof, non-contact control screen and application

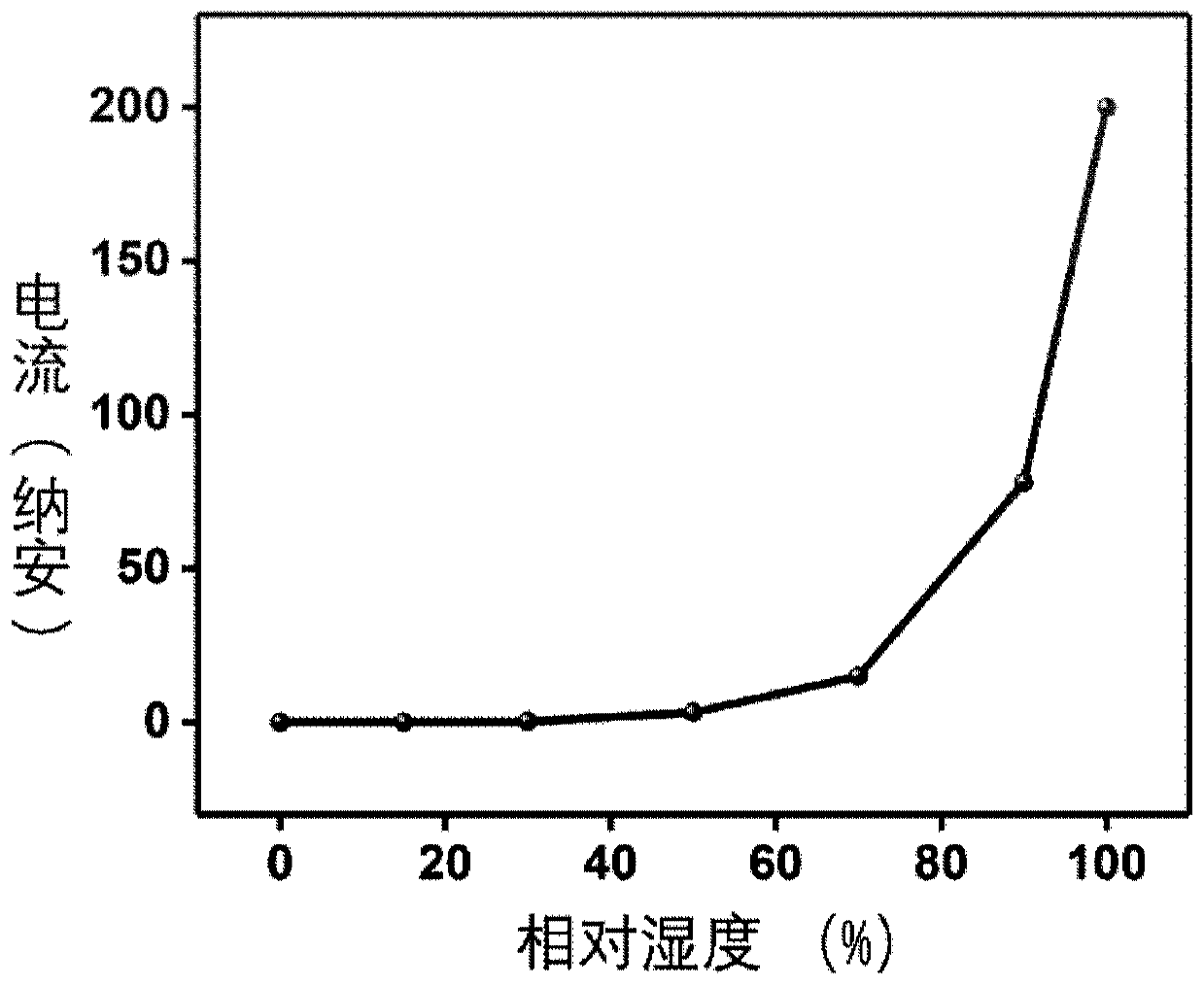

A humidity sensor, non-contact technology, applied in the direction of instruments, scientific instruments, mechanical mode conversion, etc., can solve the problems of expensive preparation equipment, complex preparation process, etc., to achieve information input, high response switch ratio, high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

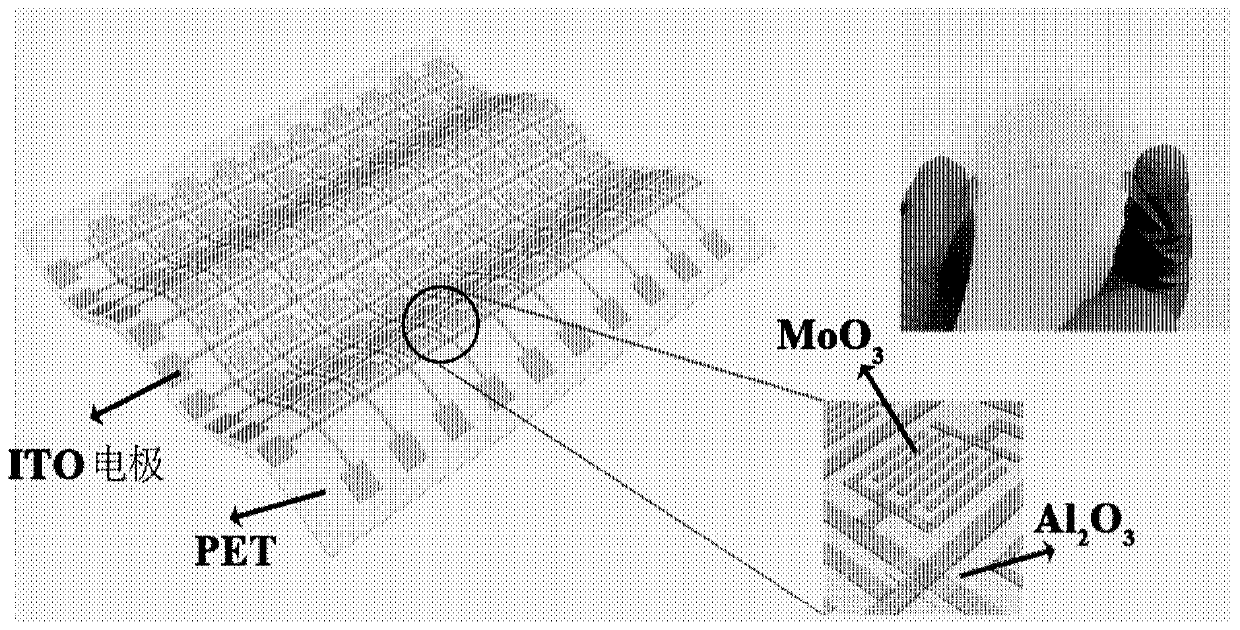

[0027] The invention discloses a preparation method of a humidity sensor, comprising:

[0028] preparing interdigitated electrodes on the substrate;

[0029] A humidity sensitive material is prepared on a substrate prepared with interdigitated electrodes, that is, the humidity sensor is obtained.

[0030] In some embodiments of the present invention, the moisture-sensitive material includes molybdenum trioxide nanosheets.

[0031] In some embodiments of the present invention, the preparation method of the molybdenum trioxide nanosheets includes:

[0032] Ammonium heptamolybdate tetrahydrate is dissolved in deionized water, and then nitric acid solution is added to carry out hydrothermal reaction. After the hydrothermal reaction is completed, the obtained white powder is annealed to obtain the molybdenum trioxide nanosheet.

[0033] In some embodiments of the present invention, the concentration of ammonium heptamolybdate tetrahydrate is 0.7 to 1.1 g / mL;

[0034] In some emb...

Embodiment 1

[0081] Preparation of MoO by hydrothermal method 3 Nanosheets. The specific steps are:

[0082] (1) Dissolve 0.88 g of ammonium heptamolybdate tetrahydrate in deionized water with a volume of 10 mL, and stir thoroughly.

[0083] (2) Add the nitric acid solution with a concentration of 4.5 mol / L dropwise into the ammonium heptamolybdate tetrahydrate aqueous solution described in step (1), and fully stir.

[0084] (3) Transfer the above-mentioned mixed solution into a reaction kettle, keep the heating temperature at 180° C., and the heating time for 180 minutes, and collect the generated white powder.

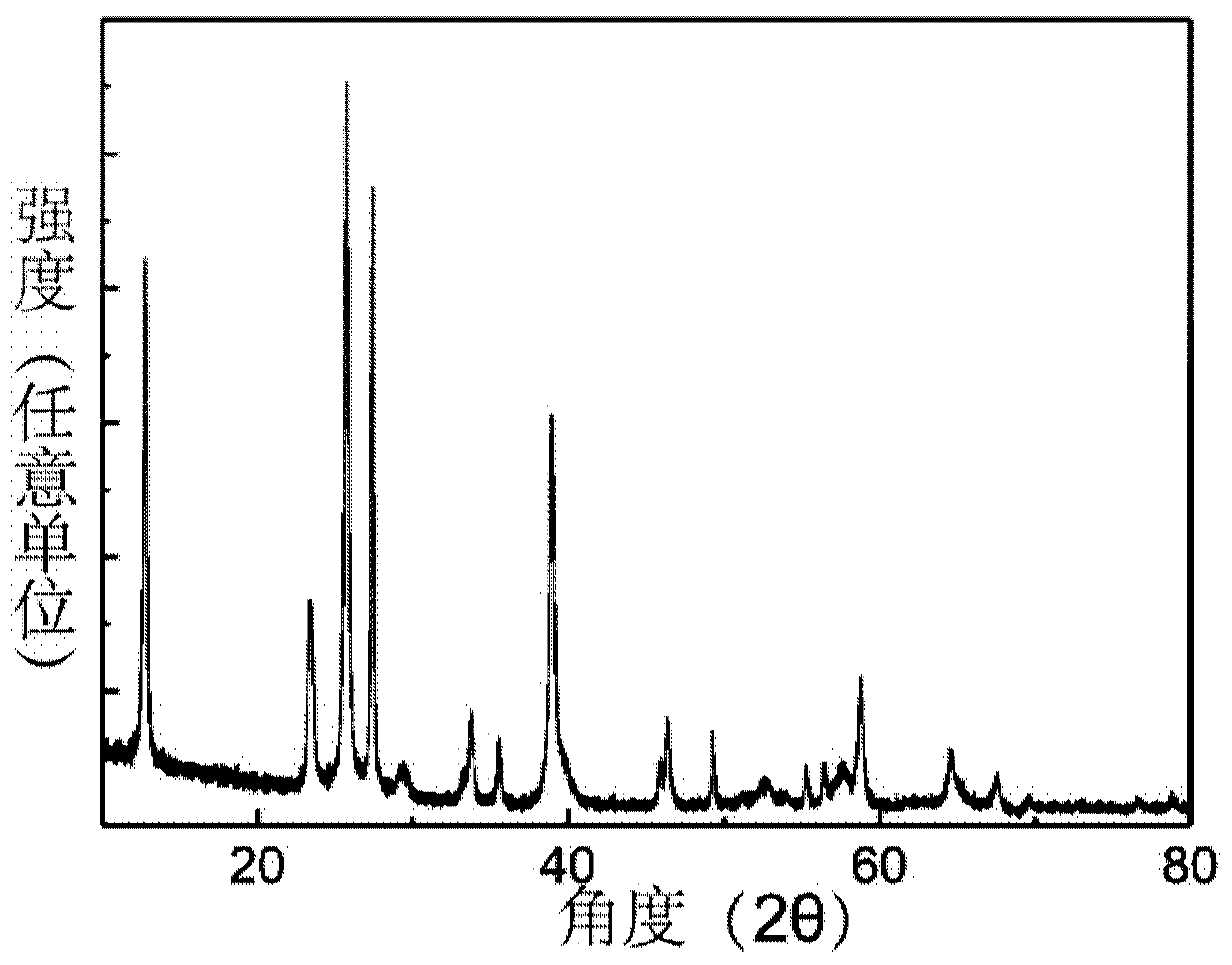

[0085] (4) Put the white powder synthesized by the hydrothermal method in a high-temperature tube furnace, anneal at 450°C for 30 minutes, wait for the tube furnace to cool to room temperature, and collect the annealed powder as MoO 3 Nanosheet powder. XRD of the powder as figure 1 As shown, it is α-phase MoO 3 .

[0086] (5) MoO 3 The nanosheet powder is ultrasonically d...

Embodiment 2

[0091] (1) Dissolve 0.95 g of ammonium heptamolybdate tetrahydrate in deionized water with a volume of 8 mL, and stir thoroughly.

[0092] (2) Add the nitric acid solution with a concentration of 5 mol / L dropwise into the ammonium heptamolybdate tetrahydrate solution described in step (1), and fully stir.

[0093] (3) Transfer the above-mentioned mixed solution into a reaction kettle, keep the heating temperature at 170° C., and the heating time at 210 minutes, and collect the generated white powder.

[0094] (4) Put the white powder synthesized by the hydrothermal method in a high-temperature tube furnace, anneal at 500°C for 40 minutes, wait for the tube furnace to cool to room temperature, and collect the annealed powder as MoO 3 Nanosheet powder.

[0095] (5) MoO 3 The nanosheet powder is ultrasonically dispersed in ethanol, and the concentration of the dispersion is 0.05 g / mL.

[0096] (6) Prepare an ITO electrode array on a flexible PET substrate with a thickness of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com