Mica tape preparation method

A technology of mica tape and mica, which is applied to mica, insulators, electrical components, etc., can solve problems such as damage and functional failure of composite materials, and achieve the effect of enhanced contact surface, enhanced mechanical strength, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

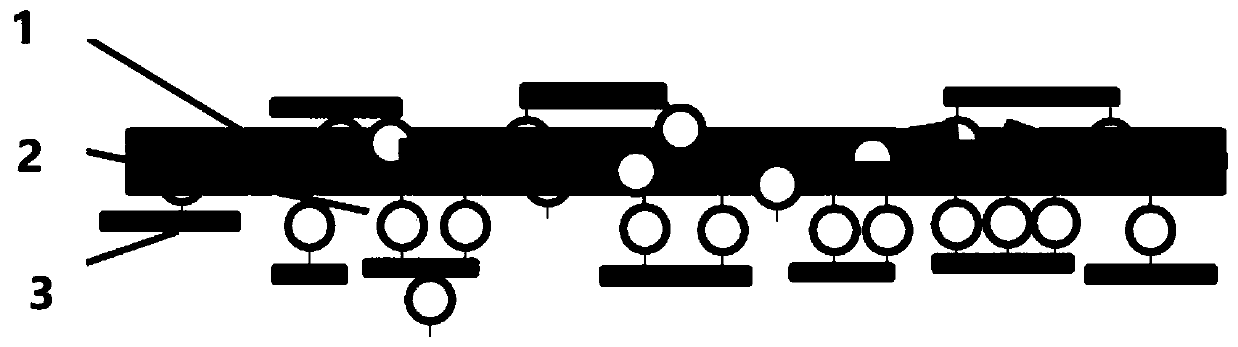

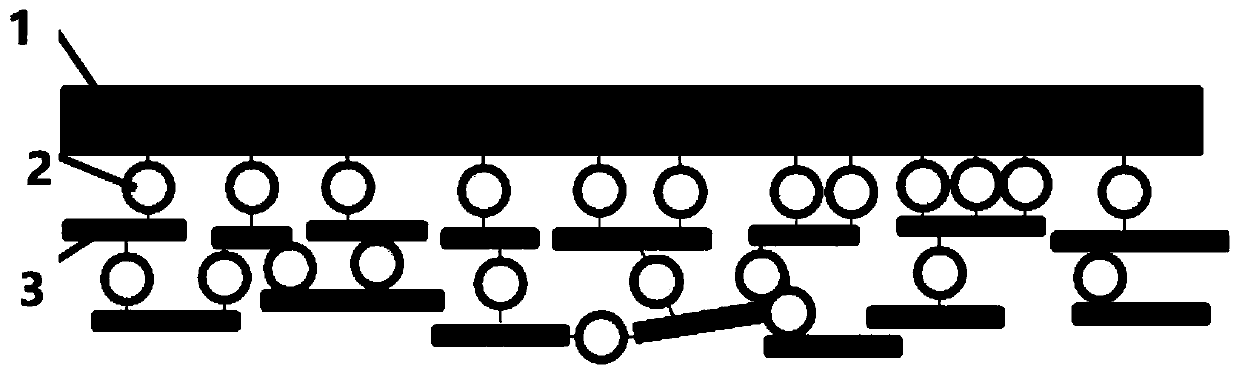

[0030] The invention provides a kind of mica tape preparation method, comprises the following steps:

[0031] 1) Carrying out the suspension of the mica fine pulp to obtain mica paper; carrying out vacuum water absorption treatment on the mica paper, and the mica paper after the vacuum water absorption treatment is in a wet state;

[0032] Sizing on fiberglass cloth;

[0033] 2) Compounding the glass fiber cloth after sizing and the mica paper prepared in step 1) through pressing rollers to obtain a composite paper cloth, wherein when bonding and pressing;

[0034] 3) The composite paper cloth is subjected to pressing treatment, drying and curing treatment, winding, and cutting to obtain the target product mica tape.

[0035] Preferably, in the mica tape preparation method, the mica fine pulp is one or more of muscovite fine pulp, phlogopite fine pulp, calcined muscovite fine pulp, calcined phlogopite fine pulp and synthetic mica fine pulp combination.

[0036] Preferably, ...

Embodiment 1

[0041] Imported Indian phlogopite mica is selected and sent to the hydraulic crusher through a conveyor, and after classification and concentration, the suspension of Indian phlogopite mica fine pulp is obtained, which is sent to the copy making machine for copy processing;

[0042] Select quantitative 32g / m 2 Glass fiber cloth, coated with silicone-modified epoxy resin emulsion; Utilize the vacuum suction roll of papermaking machine to compound the glass fiber cloth after sizing and the mica paper prepared in step 1) through pressure rolls, After the vacuum suction roller enters the press section, under the pressing action of the press section, the glass fiber cloth is pressed into the mica paper embryo to form a composite mica paper; The coiling machine forms the mica tape embryo tape. The mica tape embryo tape is cut to obtain the mica tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com