Adsorbent and method for synchronously removing ammonia nitrogen and phosphorus in sludge removal water

A technology for removing water and adsorbents, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., to achieve the effects of low preparation cost, solving large fluctuations in ammonia nitrogen and phosphorus concentrations, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

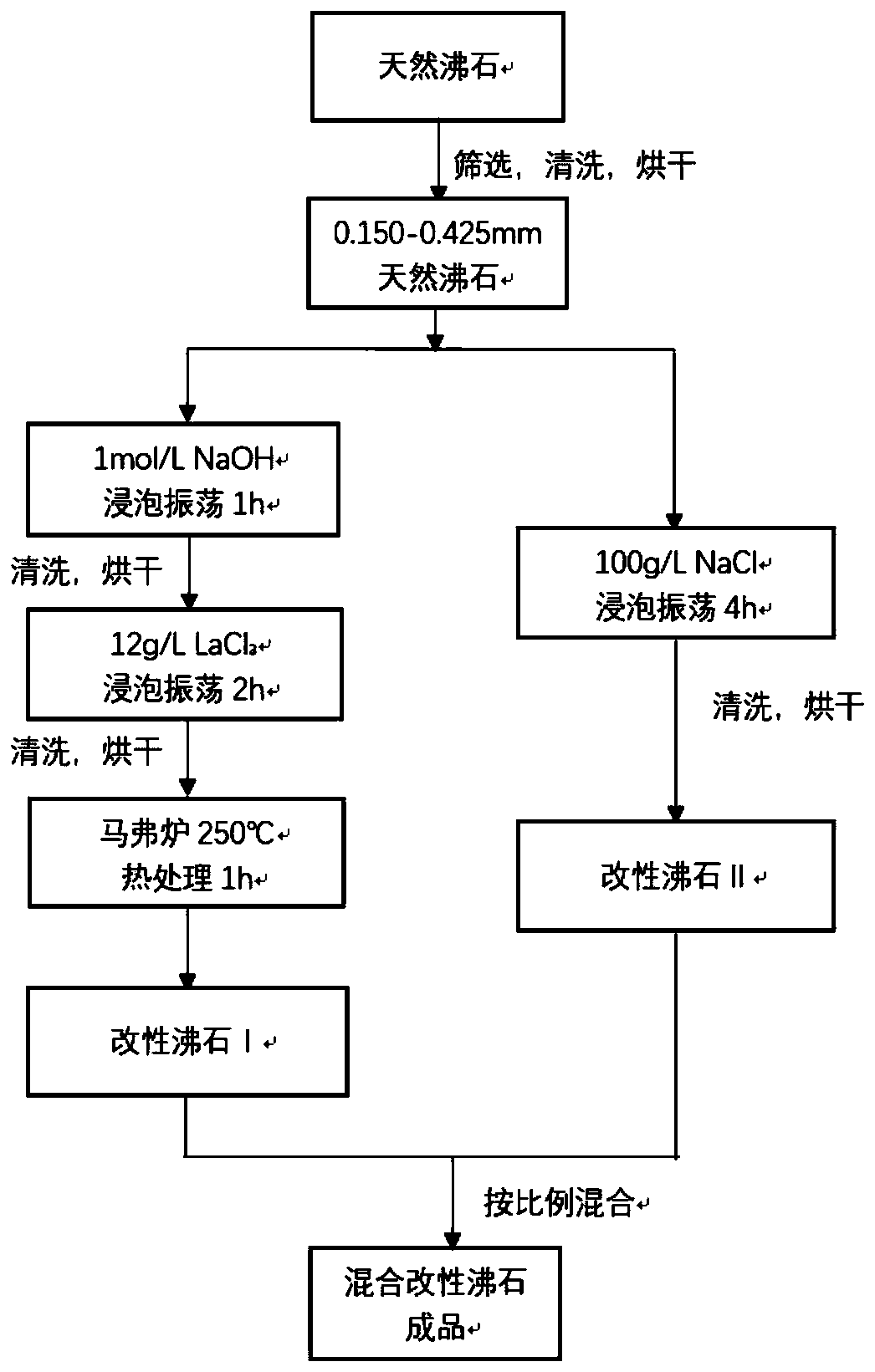

[0044] Modified zeolite I, its preparation method comprises the steps:

[0045] 1) Use a sieve to take natural zeolite with a particle size of 0.150mm to 0.425mm, wash it with deionized water until the water is clear, put it in an oven, and dry it at 105°C for 12 hours, and take it out for later use;

[0046] 2) Add 5g of the zeolite obtained in step 1) into 100ml of 1mol / L NaOH solution, shake in a constant temperature shaker in a water bath at 25°C for 2 hours, wash it with deionized water until it is neutral, and dry it for 12 hours;

[0047]3) Melt 0.6g of lanthanum chloride into 50ml of ethanol solution with a mass fraction of 20% in a 250ml Erlenmeyer flask to prepare a lanthanum chloride solution, put the Erlenmeyer flask into a water area constant temperature oscillator and vibrate at 30°C for 1h, Add 5g of zeolite to the Erlenmeyer flask, adjust the pH to 11 with 2mol / L NaOH solution, then put the Erlenmeyer flask into a constant temperature oscillator in a water bath...

Embodiment 1

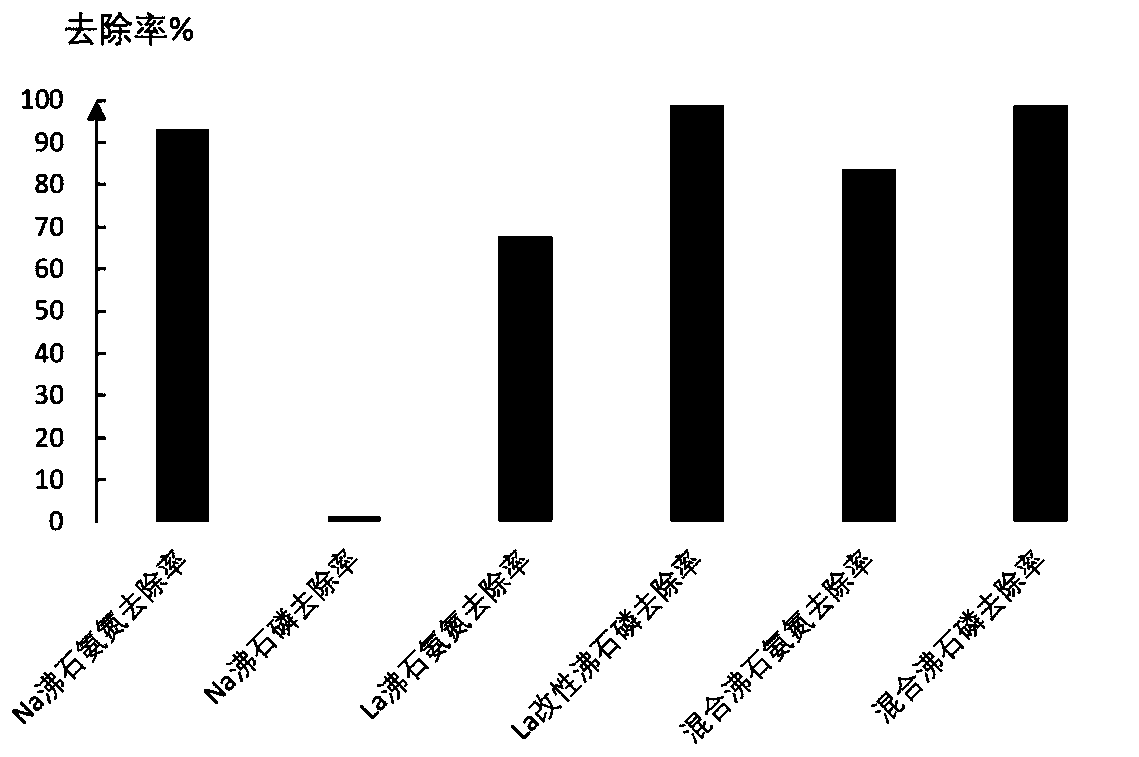

[0065] Using the above-mentioned modified zeolite I and modified zeolite II to simultaneously remove ammonia nitrogen and phosphorus in sludge removal water, the specific steps are as follows:

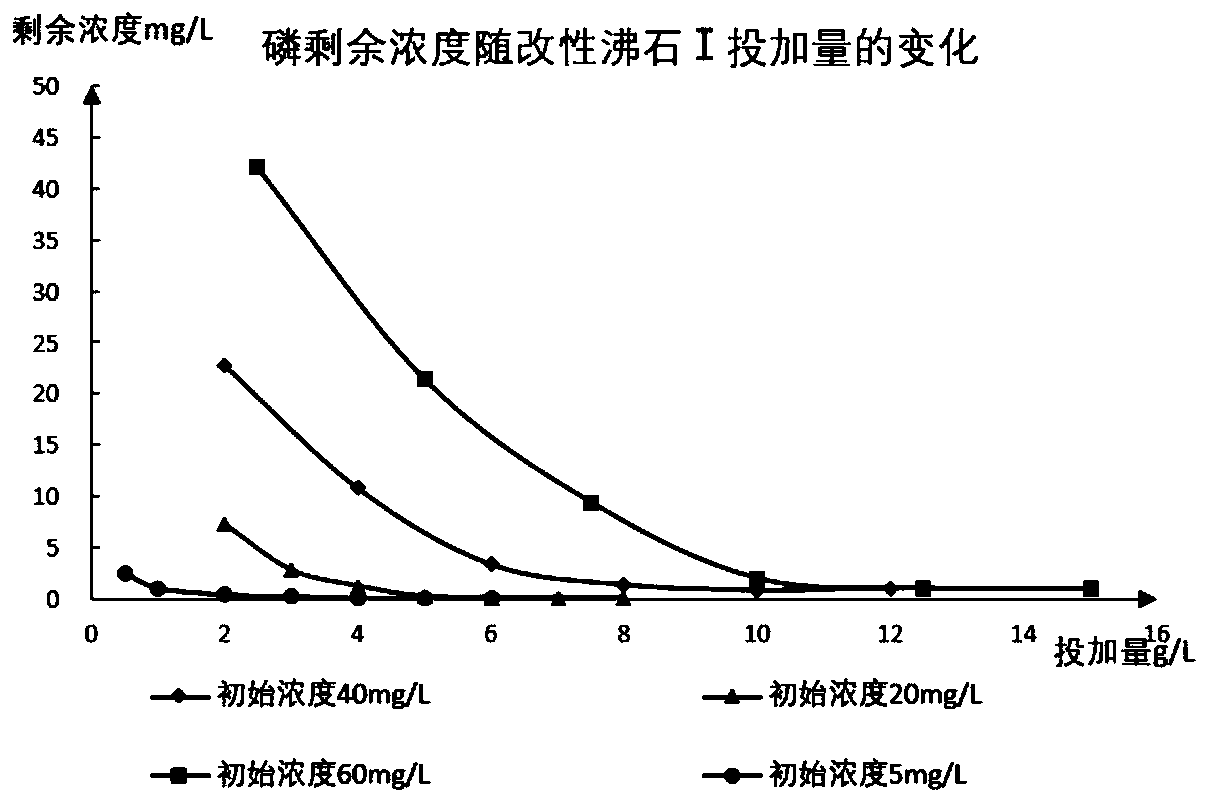

[0066] (1) Take sludge removal water from Wuhan Shahu Sewage Treatment Plant, first use molybdenum antimony anti-spectrophotometry to detect the total phosphorus concentration in sludge removal water, and the test result is 35.4mg / L, so according to y=0.1665x +0.5455(R 2 =0.9779) the dosage of modified zeolite I is 6.4g / L.

[0067] (2) Nessler's reagent was used to detect the concentration of ammonia nitrogen in the sludge removal water by spectrophotometry, and the detection result was 90.6 mg / L. According to K=5.9964C 氨氮 -0.622 (R 2 =0.9729), draw this moment K=0.364;

[0068] (3) The dosage of modified zeolite II is z, z=y 0 / K=8 / 0.364=22.0g / L;

[0069](4) Mix 6.4g / L modified zeolite I and 22.0g / L modified zeolite II evenly and add them to the sample of sludge removal water t...

Embodiment 2

[0073] Using the above-mentioned modified zeolite I and modified zeolite II to simultaneously remove ammonia nitrogen and phosphorus in sludge removal water, the specific steps are as follows:

[0074] (1) Take sludge removal water from Wuhan Shahu Sewage Treatment Plant, first use molybdenum antimony anti-spectrophotometry to detect the total phosphorus concentration in sludge removal water, and the test result is 52.6mg / L, so according to y=0.1665x +0.5455 (R2=0.9779), the dosage of modified zeolite I is 9.3g / L.

[0075] (2) Nessler's reagent was used to detect the concentration of ammonia nitrogen in the sludge removal water by spectrophotometry, and the detection result was 325.6mg / L. According to K=3.9193C 氨氮 -0.529 (R 2 =0.9964), draw this moment K=0.184;

[0076] (3) The dosage of modified zeolite II is z, z=y 0 / K=10 / 0.184=54.4g / L;

[0077] (4) Mix 9.3g / L modified zeolite I and 54.4g / L modified zeolite II evenly and add them to the sample of sludge removal water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com