Beneficiation method of low-grade copper-nickel sulfide ore

A technology for copper-nickel sulfide ore and beneficiation method, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of reducing the recovery rate of copper-nickel minerals, the effect of floating of copper-nickel minerals, and the number of additions, etc. Excellent hydrophobicity and adhesion, promoting mineral floatation and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the superhydrophobic polyurethane nanoparticles comprises the following steps:

[0043] (1) Add toluene diisocyanate and catalyst dibutyltin dilaurate to polypropylene glycol, and react at 80°C for 1 hour, then add chain extender hydroxy silicone oil, and continue to react for 2 hours to prepare organosilicon modified polyurethane;

[0044] (2) The nano-SiO 2 and the organosilicon-modified polyurethane were respectively placed in the solvent ethyl acetate, and after ultrasonic dispersion for 1 h, the nano-SiO 2 The dispersion liquid and the polyurethane dispersion liquid are uniformly mixed, and then ultrasonically dispersed for 0.5 h to obtain super-hydrophobic polyurethane nanoparticles.

[0045] In step S4, the addition amount of the collector in the first-stage cleaning is 40 g / t, the addition amount of the collector in the first-stage cleaning is 30 g / t, and the inhibitor is added in an amount of 30 g / t. The amount is 50g / t.

[0046] In...

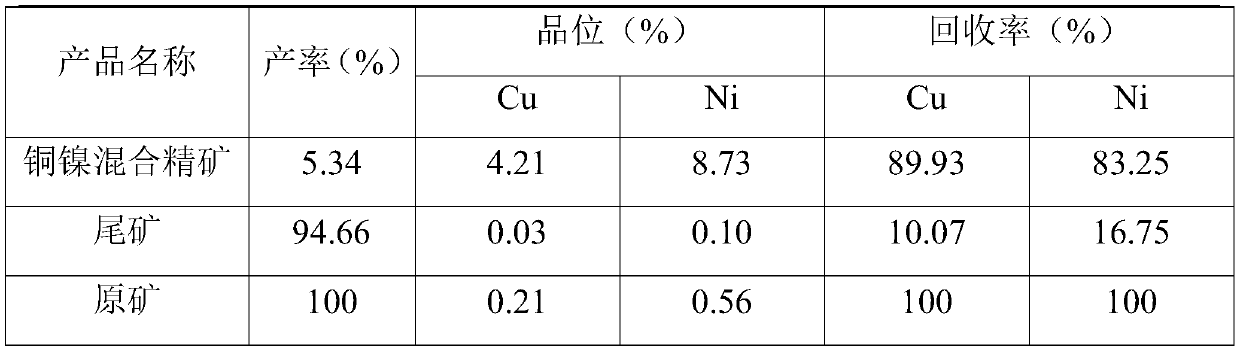

Embodiment 1

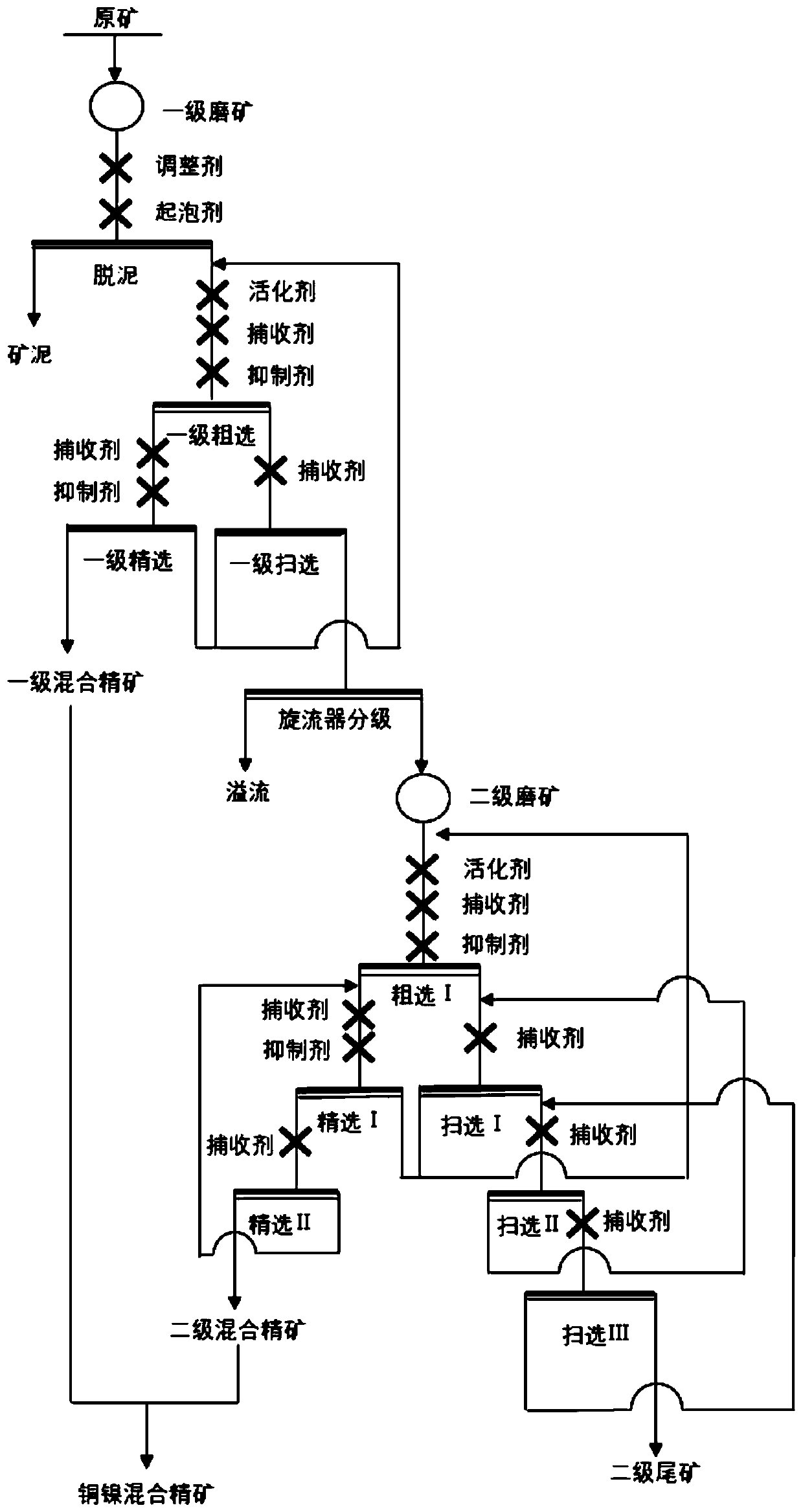

[0049] The present embodiment provides a kind of beneficiation method of low-grade copper-nickel sulfide ore, comprising the following steps:

[0050] S1. Perform primary grinding on the raw ore, so that the content of particles with a fineness of -74 μm after grinding is greater than 65%, and add water to adjust the slurry to a slurry concentration of 30%, and then add 500 g / t of sodium carbonate to the obtained slurry. As a modifier, stir for 3 minutes to adjust the slurry;

[0051] S2, add the foaming agent of 13g / t in the ore pulp obtained in step S1 to carry out desliming, and the foaming agent is a mixture of terpineol oil and dodecylamine, wherein the mass ratio of terpineol oil and dodecylamine is 1 :2;

[0052] S3. Add 80g / t copper sulfate as activator to the deslimed pulp, add 70g / t superhydrophobic polyurethane nanoparticles as collector after stirring for 3min, add 100g / t carboxymethyl carboxymethyl after stirring for 3min Sodium cellulose is used as an inhibitor...

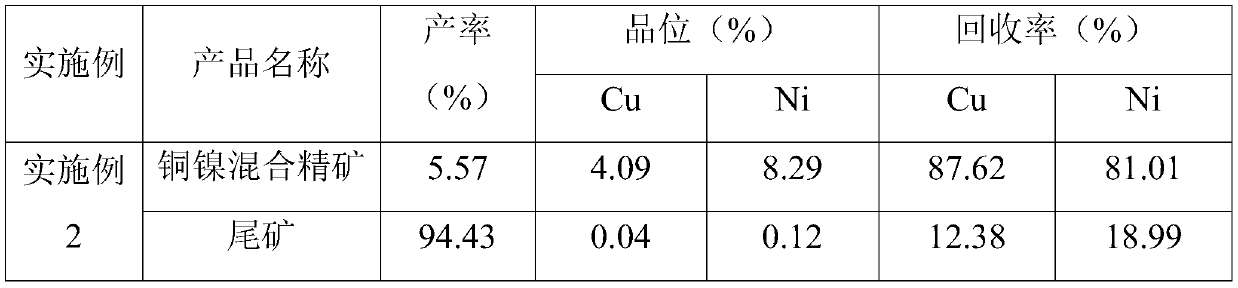

Embodiment 2~5 and comparative example 1

[0064] Embodiments 2 to 5 and Comparative Example 1 respectively provide a kind of beneficiation method of low-grade copper-nickel sulfide ore. Compared with Embodiment 1, the difference of Embodiments 2 to 5 is that the amount of foaming agent in step S2 is changed. The mass ratio of terpineol oil and dodecylamine in the addition amount or the foaming agent; the difference of Comparative Example 1 is that the foaming agent used in step S2 only contains terpineol oil; Examples 2 to 5 and Comparative Example 1 correspond to The relevant parameters are shown in Table 2.

[0065] Table 2 Relevant parameters in Examples 2 to 5 and Comparative Example 1

[0066] Example Additive amount of foaming agent (g / t) Mass ratio of terpineol oil and dodecylamine Example 2 10 1:2 Example 3 15 1:2 Example 4 13 1:3 Example 5 13 1:1 Comparative Example 1 13 1:0

[0067] The minerals obtained by the separation of Examples 2 to 5 and Comparativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com