Aramid fiber/carbon nanotube hybrid airgel film, its preparation method and application

A technology of carbon nanotubes and aerogels, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems that are difficult to meet market needs, achieve excellent Joule heating effect and electromagnetic shielding performance, and have broad application prospects. The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

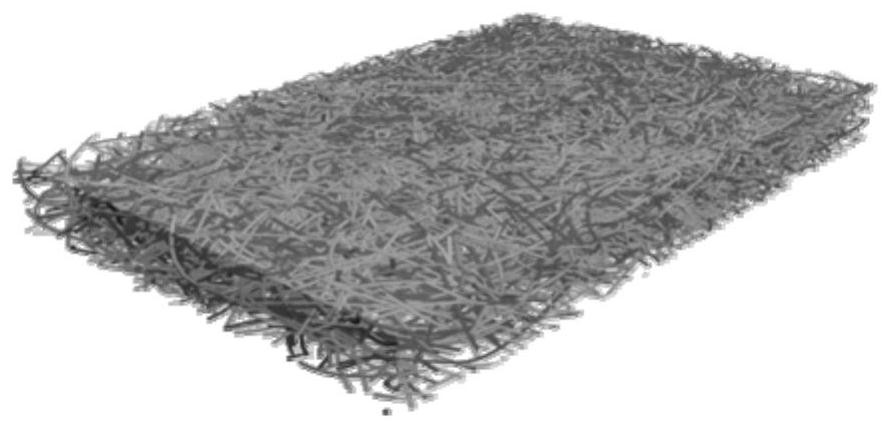

[0043] Another aspect of the embodiments of the present invention also provides a method for preparing an aramid / carbon nanotube hybrid aerogel film, which includes:

[0044] At least uniformly mix the carbon nanotube dispersion and the aramid nanofiber dispersion to form the aramid nanofiber / carbon nanotube mixed dispersion;

[0045] The aramid nanofiber / carbon nanotube mixed dispersion is applied on a substrate, then transferred to a coagulation bath, and a hybrid gel film is formed by sol-gel replacement;

[0046] drying the hybrid gel film to obtain a hybrid aerogel film;

[0047] The hybrid aerogel film is infiltrated with at least a hydrophobic resin solution, and dried, so that at least part of the hydrophobic resin covers the hybrid aerogel film to obtain an aramid fiber / carbon nanotube hybrid aerogel film.

[0048] In a more preferred embodiment, the preparation method of the aramid fiber / carbon nanotube hybrid aerogel film comprises:

[0049] (1) dispersing carbon ...

Embodiment 1

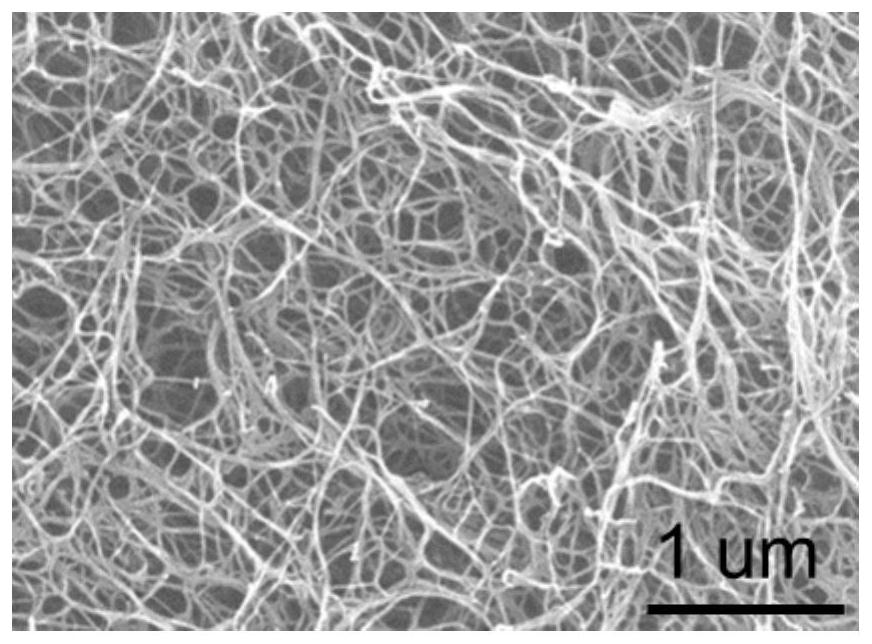

[0078] Multi-walled carbon nanotubes are added to dimethyl sulfoxide, and the mass fraction of multi-walled carbon nanotubes dispersion is 0.1wt%. Stir at 20°C to prepare a mass fraction of 0.1wt% para-aramid nanofiber dispersion; then mix the multi-walled carbon nanotube dispersion and para-aramid nanofiber dispersion in a mass ratio of 0.2:1, Spin coating at 5000 rpm, then transfer to an ethanol coagulation bath to perform sol-gel replacement with water to form a hybrid gel film, and then supercritically dry to obtain a hybrid aerogel film; The gel film was immersed in the silicone resin solution for 1 s, taken out, and dried at room temperature to obtain an aramid / carbon nanotube hybrid aerogel film with a thickness of 10 μm. figure 2 The SEM photograph of the aramid / carbon nanotube hybrid aerogel film obtained in this example is shown. For other parameters, please refer to Table 1.

Embodiment 2

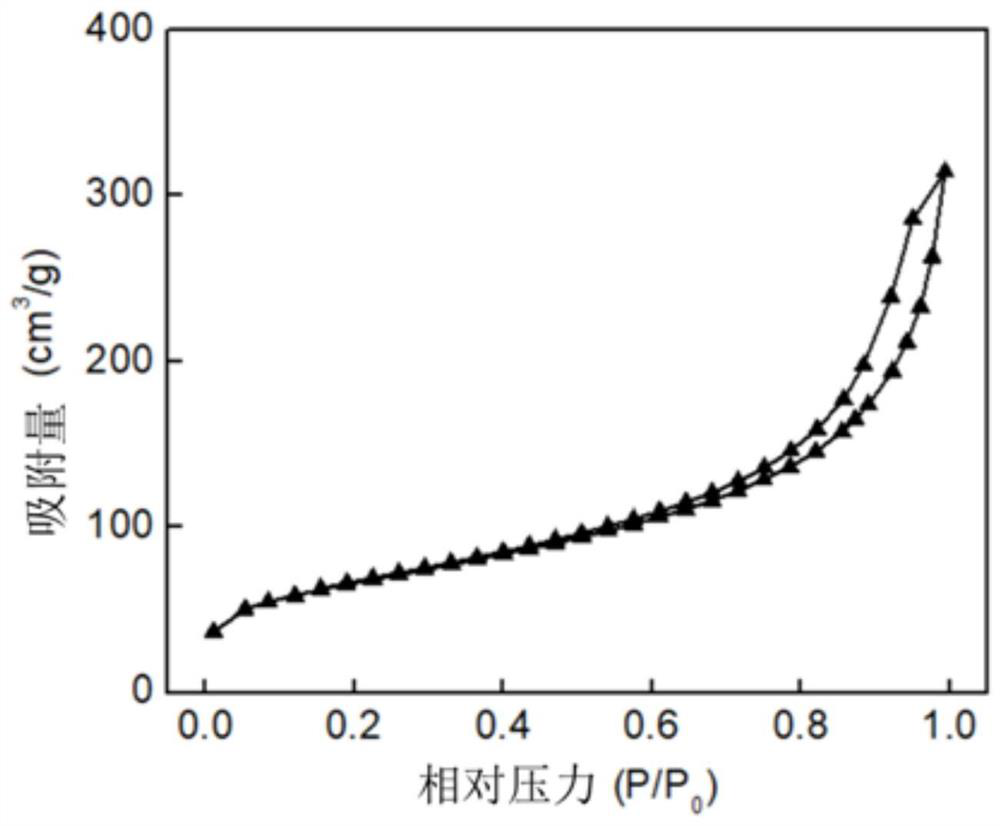

[0080] The single-walled carbon nanotubes were added to N-methylpyrrolidone to prepare a single-walled carbon nanotube dispersion with a mass fraction of 0.5 wt%, and para-aramid fiber and potassium tert-butoxide were added to N - Stir in methyl pyrrolidone at 30°C to prepare a mass fraction of 10wt% para-aramid nanofiber dispersion; then mix the single-walled carbon nanotube dispersion and para-aramid nanofiber dispersion in a mass ratio of 1:0.2 Mix uniformly, spin coating, the rotation speed is 500 rpm, then transfer to methanol coagulation bath to perform sol-gel replacement with ethanol to form a hybrid gel film, and then freeze-dry at -80 ° C under the condition of less than 0.1 kPa to obtain Hybrid aerogel film; the hybrid aerogel film is immersed in a silicone modified resin solution for 30s, taken out, and dried at room temperature to obtain an aramid / carbon nanotube hybrid aerogel film with a thickness of 500 μm. image 3 The nitrogen isotherm adsorption and desorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com