Porous nitrogen-doped graphene composite cobalt phosphide nanosheet and preparation method and application thereof

A nitrogen-doped graphene and cobalt phosphide technology, applied in the field of electrocatalytic materials, can solve problems such as low electrical conductivity, and achieve the effects of high controllability, low price and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

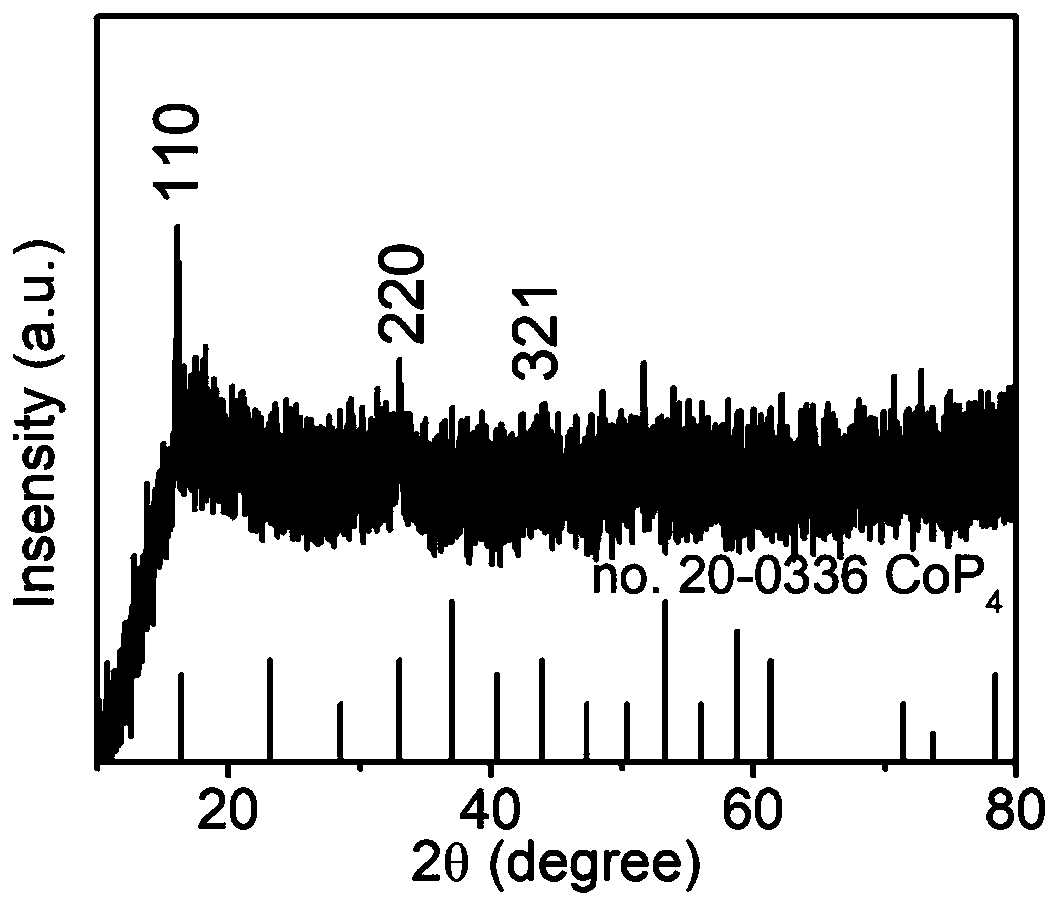

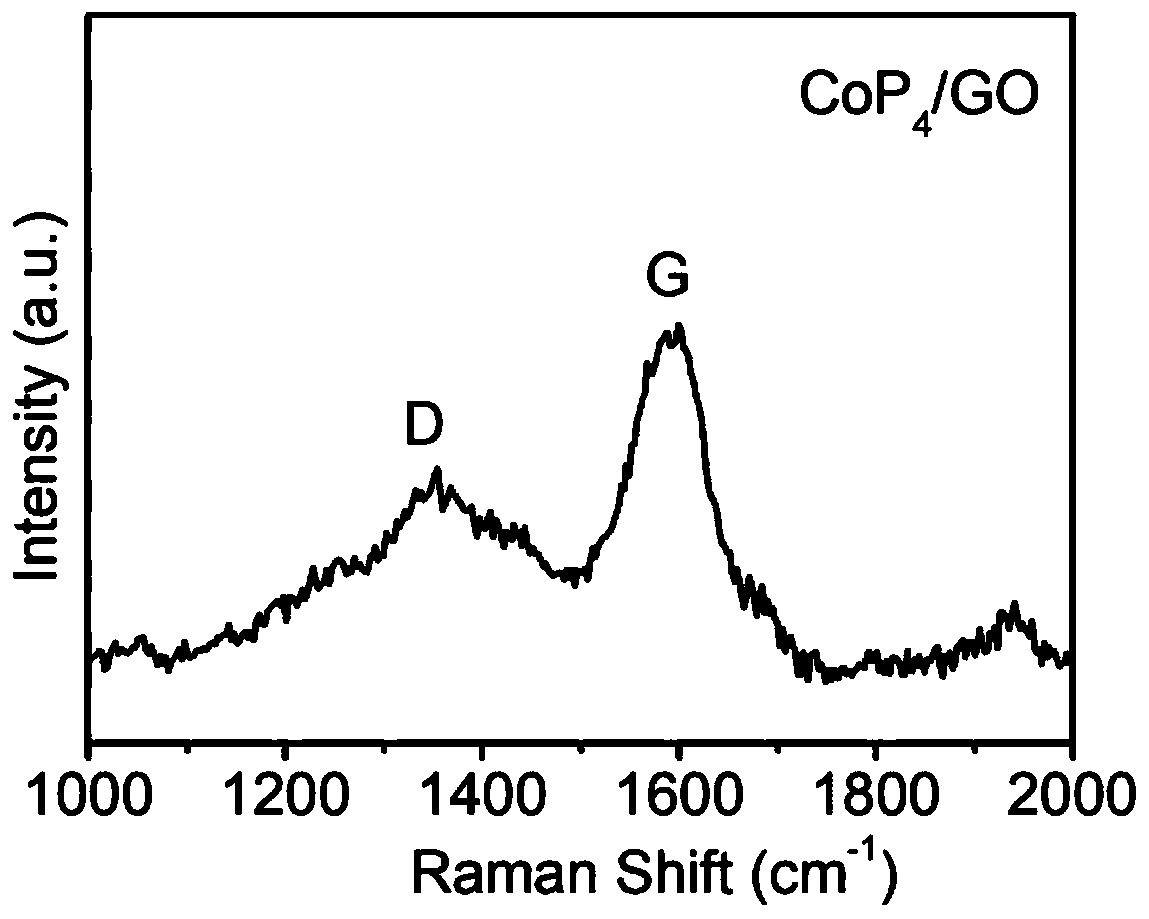

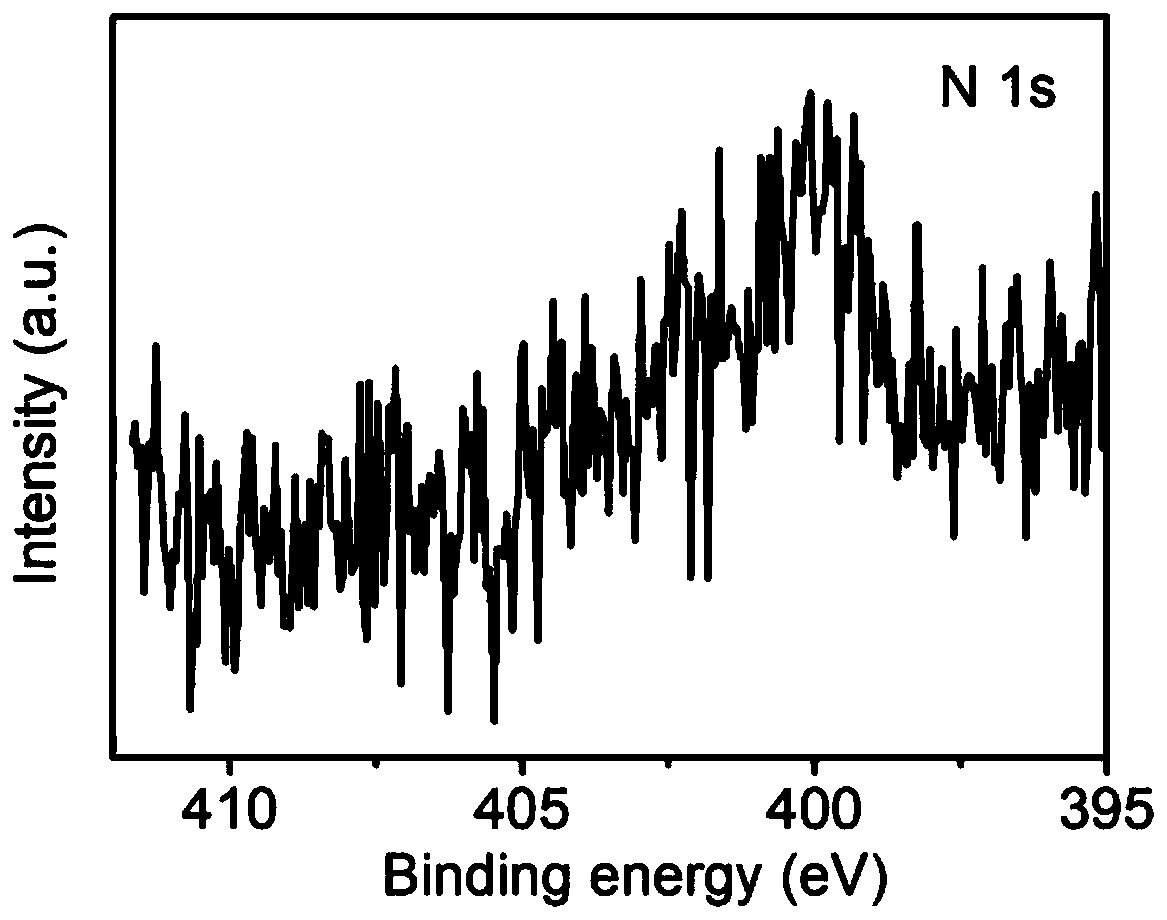

[0034] 0.1mol cobalt chloride hexahydrate, 0.15mol tetrabutylphosphine chloride and 4g urea were used to form uniform DESs in an oil bath at 60°C. Pipette 100 μL of DESs and drop-coat it on carbon cloth, place it in an ark with a cover and bake it in a muffle furnace. The baking conditions: 5°C / min to 450°C, keep it warm for 4h to obtain porous graphene composite cobalt phosphide nanosheets catalyst.

Embodiment 2

[0036] 0.1mol cobalt chloride hexahydrate, 0.15mol tetrabutylphosphine chloride and 4g urea were used to form uniform DESs in an oil bath at 60°C. Pipette 100 μL of DESs and drop-coat it on carbon cloth, place it in an ark with a cover and bake it in a muffle furnace. Baking conditions: 5°C / min to 300°C, keep warm for 4h to obtain porous graphene composite cobalt phosphide nanosheets catalyst.

Embodiment 3

[0038] 0.1mol cobalt chloride hexahydrate, 0.15mol tetrabutylphosphine chloride and 4g urea were used to form uniform DESs in an oil bath at 60°C. Pipette 100 μL of DESs and drop-coat it on the carbon cloth, place it in an ark with a cover and bake it in a muffle furnace. The baking conditions: 5°C / min to 600°C, keep warm for 4h to obtain porous graphene composite cobalt phosphide nanosheets catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com