Expandable novel epoxy resin composite flame-retardant material and preparation method thereof

An epoxy resin and composite flame retardant technology, applied in the field of flame retardants, can solve problems such as complex synthetic routes, and achieve the effects of wide source of raw materials, high limiting oxygen index and thermal stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

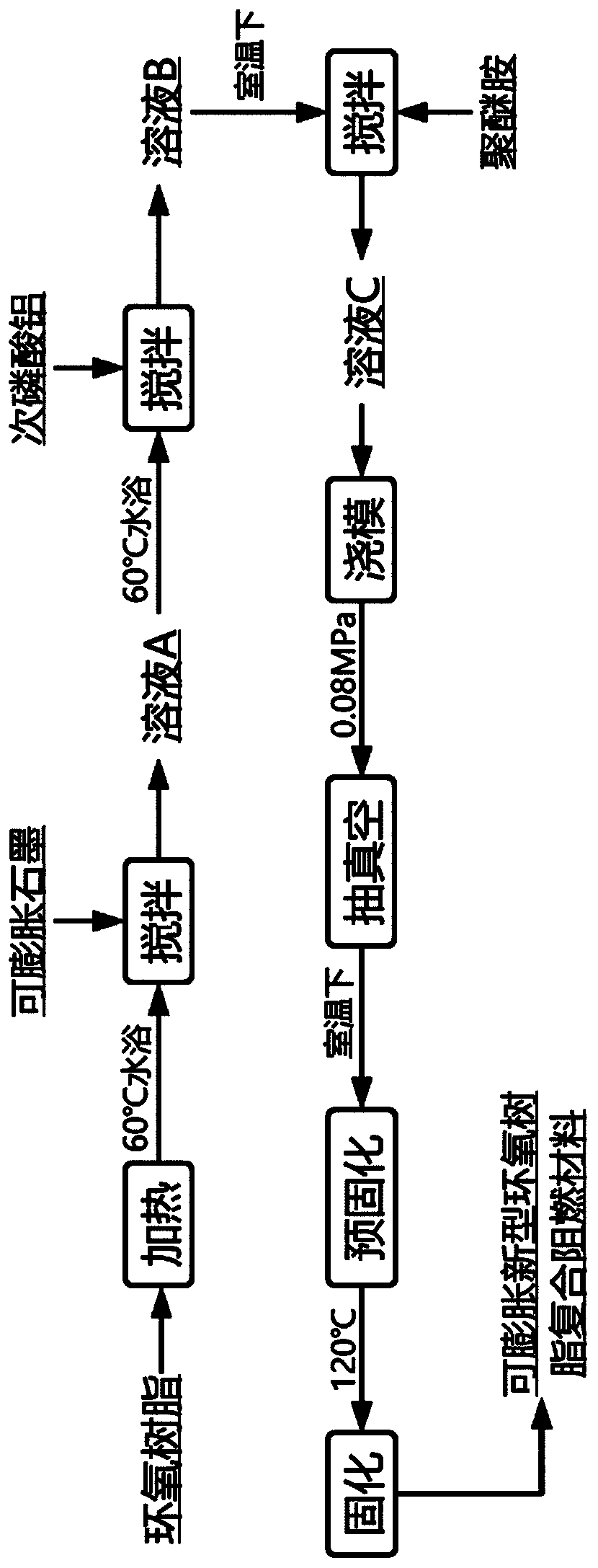

Method used

Image

Examples

Embodiment 1

[0037] The preparation of pure epoxy resin specifically comprises the steps:

[0038] Add 22.5 parts of polyetheramine to 67.5 parts of epoxy resin, stir at room temperature at a speed of 500 rpm for ten minutes, pour into a mold and pre-cure overnight at room temperature, and then cure at a constant temperature of 120 °C in a drying oven for 4 hours, remove from the mold.

[0039] Referring to Table 1, it can be seen that the oxygen index of Example 1 is only 20.4%, and there is no vertical combustion level.

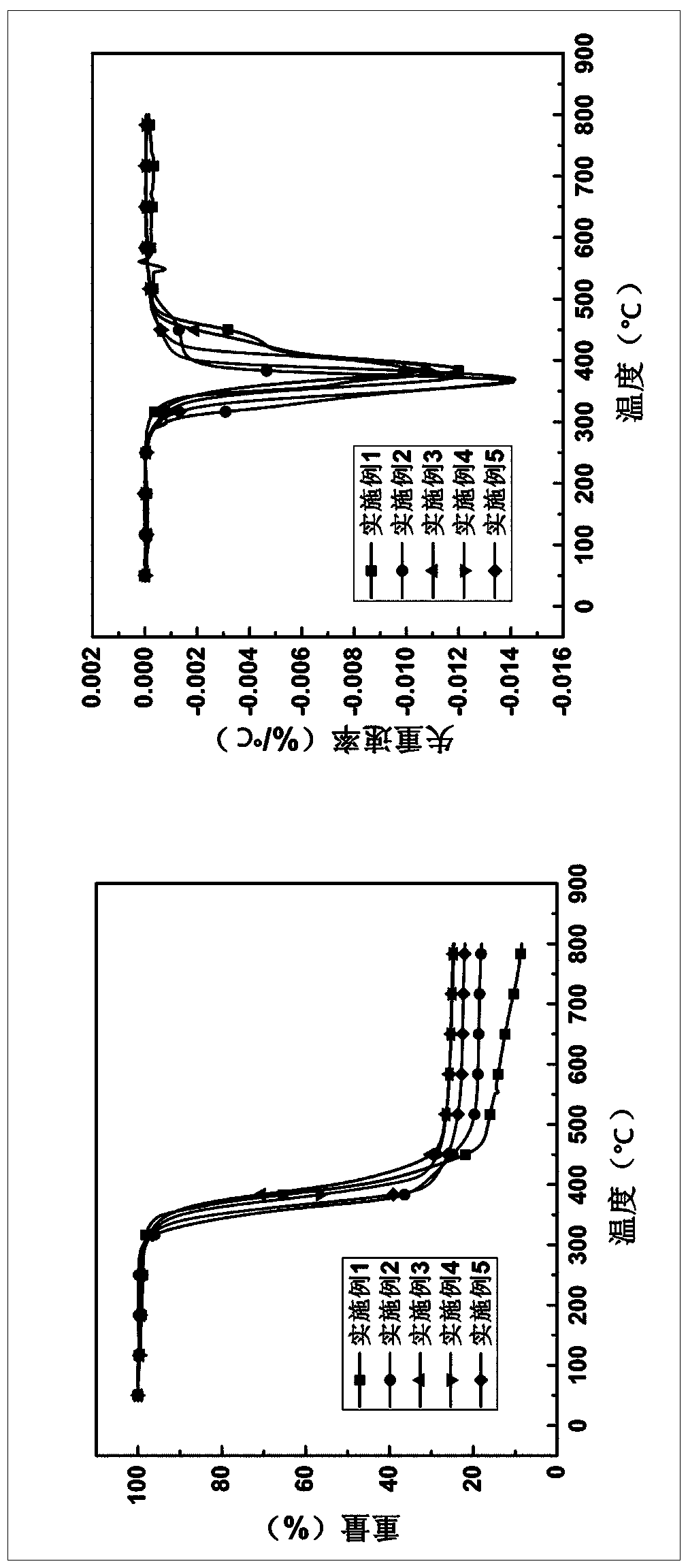

[0040] See attached figure 1 with attached figure 2 , which are the thermogravimetric (left) and thermogravimetric rate (right) curves of the example in a nitrogen atmosphere. It can be seen from the thermogravimetric diagram that the thermogravimetric loss can be divided into three stages. The first stage is the evaporation of the solvent at 0°C~300°C, the second stage is the thermal decomposition of the material at 300°C~450°C, and the third stage is at 450°C~ 80...

Embodiment 2

[0042] Add the preparation of the epoxy resin composite fire-retardant material of aluminum hypophosphite separately, specifically comprise the steps:

[0043] Add 10 parts of aluminum hypophosphite to 67.5 parts of epoxy resin, stir at 500 rpm for ten minutes in a water bath at 60°C, then add 22.5 parts of polyetheramine, and stir at 500 rpm at room temperature After stirring for ten minutes, pour into the mold and pre-cure overnight at room temperature, then cure in a drying oven at a constant temperature of 120°C for 4 hours, and take it out for demoulding.

[0044] Referring to Table 1, it can be seen that the oxygen index of Example 2 is 22.6%, which is 2.4% higher than the 20.4% of Example 1, and the vertical combustion is still no grade.

[0045] See attached figure 1 , which is the thermogravimetric (left) and thermogravimetric rate (right) curves of Example 2 under a nitrogen atmosphere. It can be seen that the temperature (T 5% ) is 313 ℃, the temperature of the p...

Embodiment 3

[0047] Add the preparation of the epoxy resin composite fire-retardant material of expandable graphite separately, specifically comprise the steps:

[0048] Add 10 parts of expandable graphite to 67.5 parts of epoxy resin, stir at 500 rpm for ten minutes in a water bath at 60°C, then add 22.5 parts of polyetheramine, and stir at 500 rpm at room temperature After stirring for ten minutes, pour into the mold and pre-cure overnight at room temperature, then cure in a drying oven at a constant temperature of 120°C for 4 hours, and take it out for demoulding.

[0049] Referring to Table 1, it can be seen that the vertical combustion of Example 3 is still gradeless, and the oxygen index is 25.2%, which is 4.8% higher than the 20.4% of Example 1, and 2.6% higher than the 22.6% of Example 2. It can be seen from this Adding expandable graphite alone has a better flame retardant effect than aluminum hypophosphite.

[0050] See attached figure 1 , which is the thermogravimetric (left) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com