Oyster potato egg roll and preparation method thereof

A technology of potatoes and mashed potatoes, which is applied in the field of food processing, can solve the problems of lack of innovation, single technology, and impracticability, and achieve the effects of edible value, reducing environmental pollution, and promoting dough formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

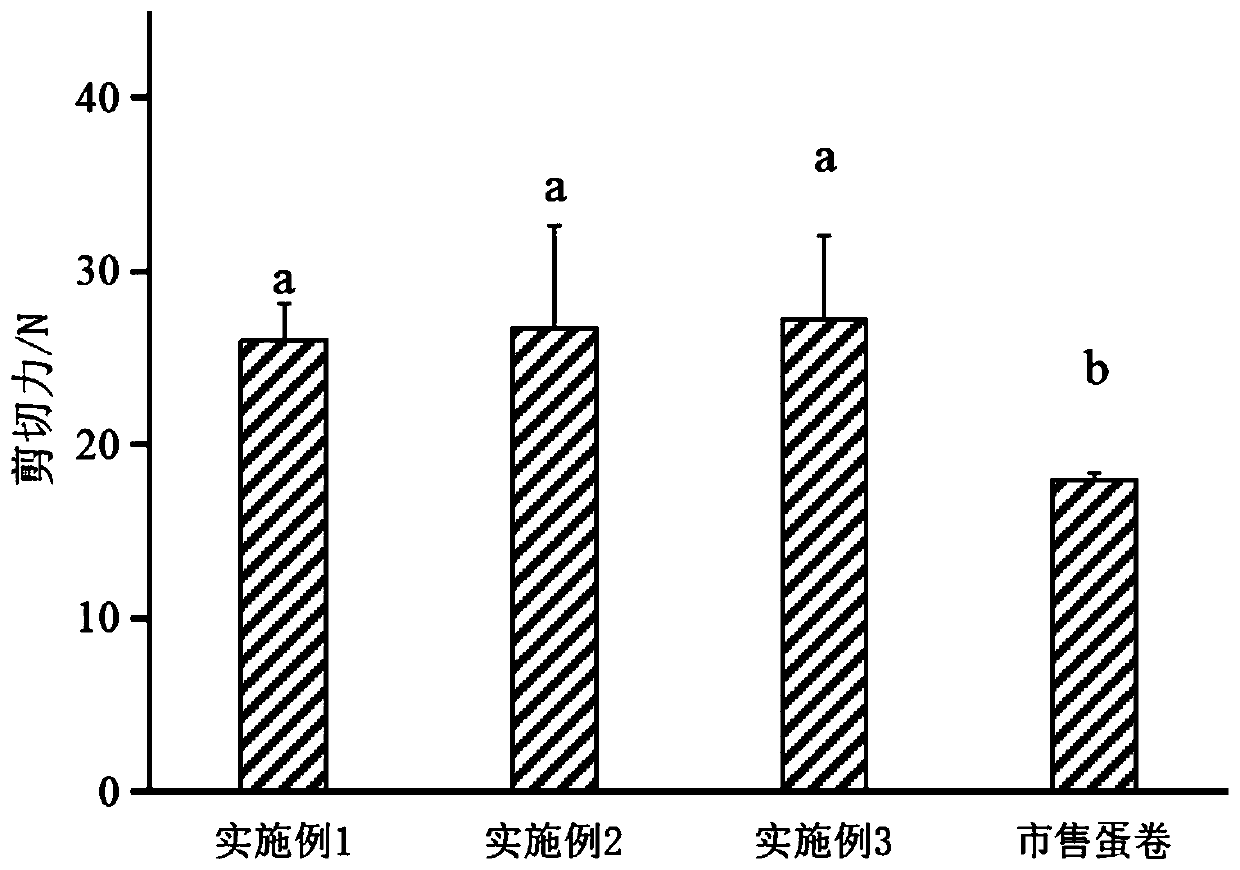

Examples

Embodiment 1

[0041] A preparation method of oyster potato omelet, comprising steps:

[0042] S1. Preparation of mashed potatoes: put 310 parts by weight of potatoes into an oven, set the relative humidity to 0%, wind speed 1 (7.5m / s), bake at 180°C for 1.1h, cool to room temperature, peel and cut into pieces Cube potato pieces of 4cm×4cm×4cm are squeezed twice with a noodle press, and the mashed potatoes obtained from the extrusion are put into an oven with a relative humidity of 0% and a wind speed of 3 gears (10.5m / s), baked at 165°C 15min to obtain baked mashed potatoes; the noodle pressing machine is the fifth generation noodle-making machine of Beige, and the thickness of the bottom plate of the noodle-making machine is 1.8mm;

[0043] S2, beating: mix 15 parts by weight of palm oil, 15 parts by weight of egg liquid and 15 parts by weight of whipping cream, beat with an egg beater for 2 minutes until uniform, and obtain emulsified pulp;

[0044] S3. Dough preparation: 180 parts by we...

Embodiment 2

[0048] A preparation method of oyster potato omelet, comprising steps:

[0049] S1. Preparation of mashed potatoes: put 345 parts by weight of potatoes into an oven, set the relative humidity to 0%, wind speed 1 (7.5m / s), bake at 200°C for 1h, cool to room temperature, peel and cut into 4cm × 4cm × 4cm square potato pieces, extruded 3 times with a noodle press, put the mashed potatoes into the oven, set the relative humidity to 0%, wind speed 3 (10.5m / s), bake at 170°C for 10min , to obtain baked mashed potatoes; the noodle press is the fifth generation noodle maker of Beige, and the thickness of the bottom plate of the noodle maker is 1.8mm;

[0050] S2, beating: mix 20 parts by weight of palm oil, 20 parts by weight of egg liquid and 20 parts by weight of whipped cream, beat with an egg beater for 1.5 minutes until uniform, and obtain emulsified pulp;

[0051] S3, dough preparation: 200 parts by weight of the baked mashed potatoes obtained in step S1, 60 parts by weight of ...

Embodiment 3

[0055] A preparation method of oyster potato omelet, comprising steps:

[0056] S1. Preparation of mashed potatoes: put 380 parts by weight of potatoes into an oven, set the relative humidity to 0%, wind speed 1 (7.5m / s), bake at 220°C for 0.9h, cool to room temperature, peel and cut into pieces Cube potato pieces of 4cm×4cm×4cm are squeezed 4 times with a noodle press, and the mashed potatoes obtained from the extrusion are placed in an oven with a relative humidity of 0% and a wind speed of 3 gears (10.5m / s), baked at 175°C 5min to obtain baked mashed potatoes; the noodle pressing machine is the fifth generation noodle-making machine of Beige, and the thickness of the bottom plate of the noodle-making machine is 1.8mm;

[0057] S2, beating: mix 25 parts by weight of palm oil, 25 parts by weight of egg liquid and 25 parts by weight of whipping cream, beat with an egg beater for 1 minute until uniform, and obtain emulsified pulp;

[0058] S3. Dough preparation: 220 parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com