Morchella esculenta seasoning base material and preparation method thereof, and morchella esculenta seasoning

A seasoning base material, morel technology, applied in the direction of food science, etc., can solve the problems of damaged morel utilization, waste, defective, etc., to improve the umami taste and increase freshness, save time, and storage resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

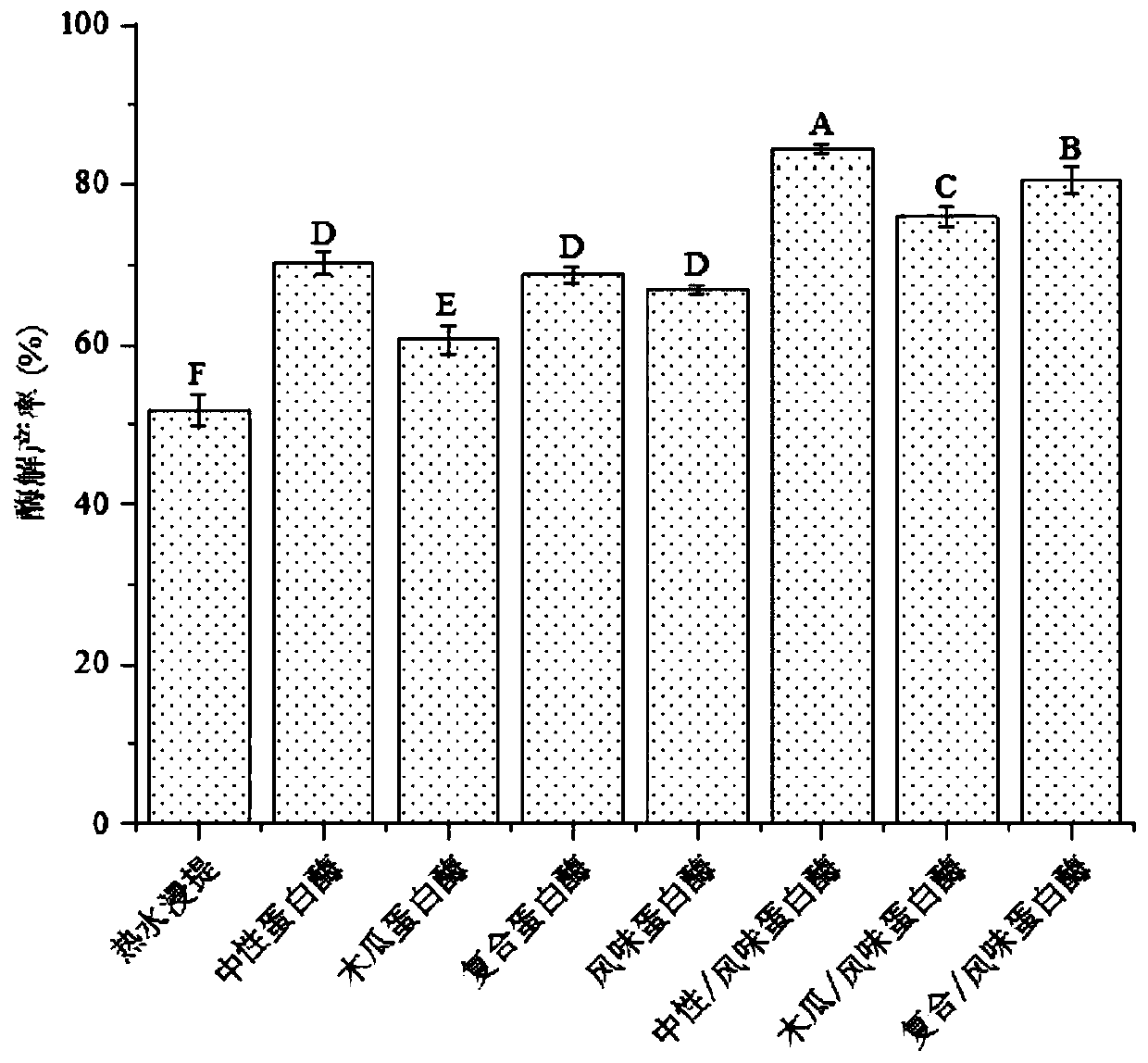

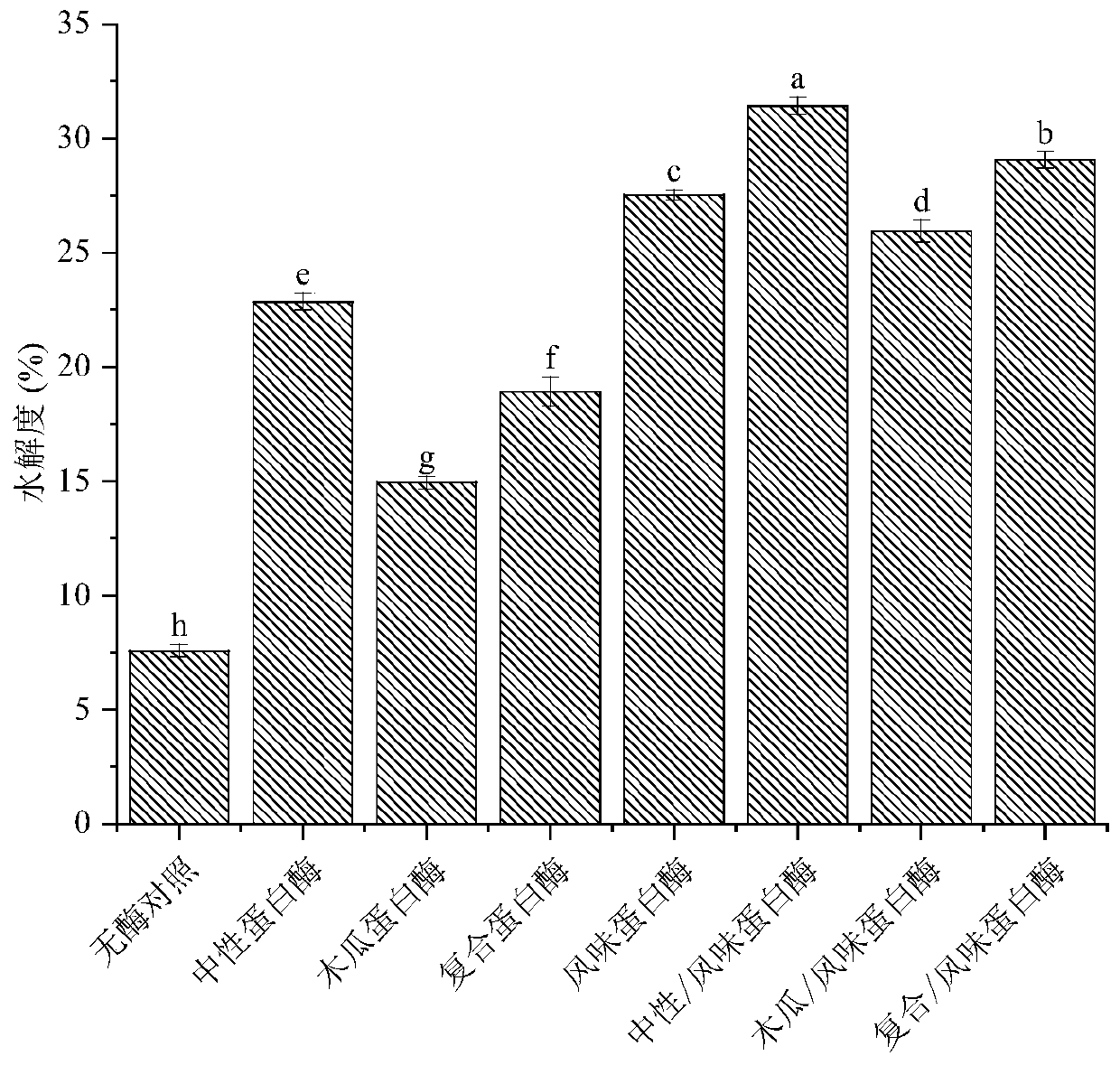

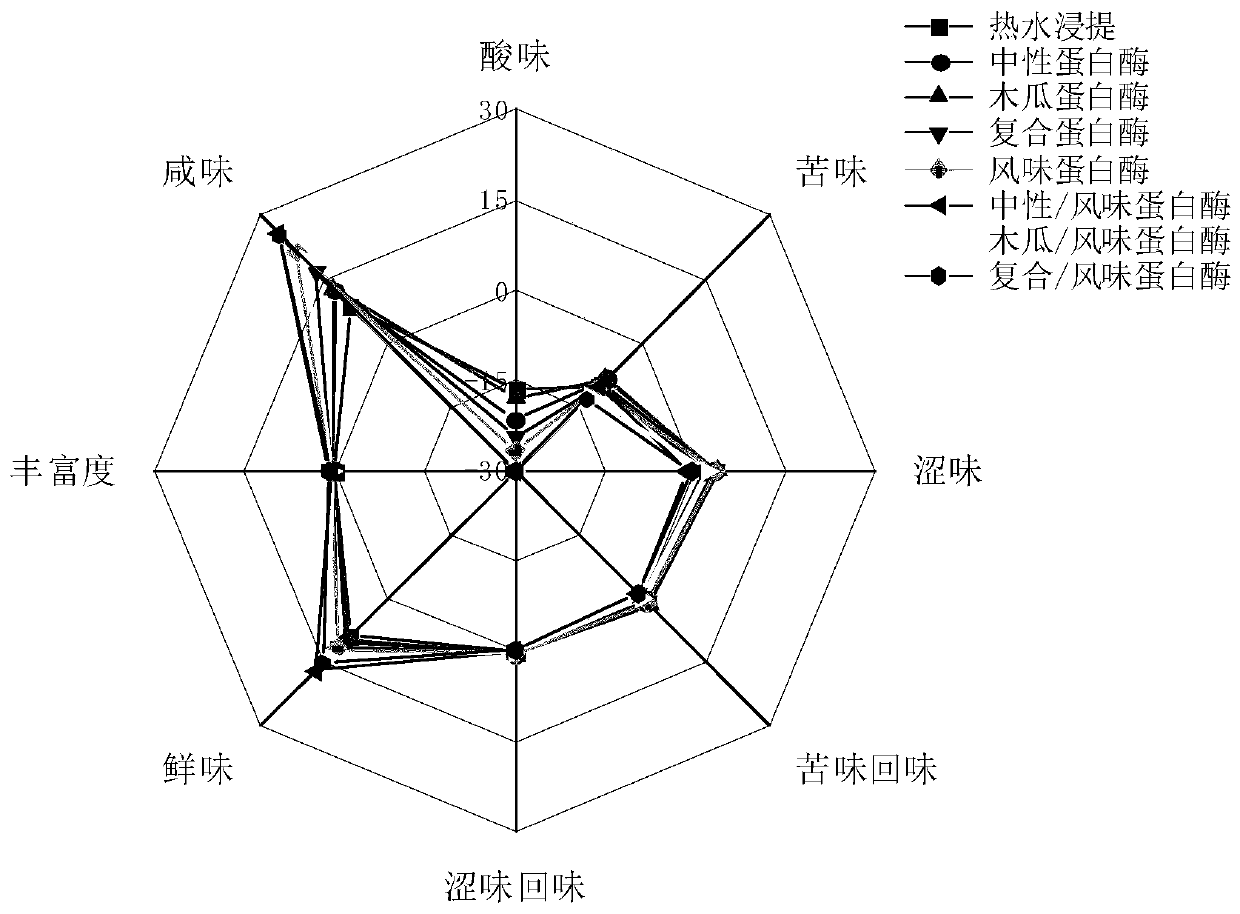

[0052] Taking the yield of enzymatic hydrolysis, degree of hydrolysis, electronic tongue radar map and corresponding intensity of taste as the index, the effect of different enzymatic hydrolysis methods on the enzymatic hydrolyzate of Morchella was investigated.

[0053] Neutral protease (enzyme activity 50000U / g), papain (enzyme activity 100000U / g), flavor protease (enzyme activity 30000U / g), compound protease (enzyme activity 100000U / g), were purchased from Beijing Soleibao Technology Co., Ltd. company

[0054] The specific experiment is as follows: each group takes 50 g of dried morel powder, mixes it with pure water at a mass ratio of 1:10 and homogenizes it, and then processes it separately through the following eight processing methods (each group does 3 parallel experiments, and takes the average value) Morchella slurry to obtain Morchella extract.

[0055] Hot water extraction method: hot water extraction at a temperature of 55°C for 3 hours.

[0056] Single enzymati...

Embodiment 2

[0071] Preparation of hickory chick enzymolysis solution: take 50 g of dried hickory chick powder (40 mesh), mix and homogenize with pure water at a mass ratio of 1:10 to obtain hickory chick slurry, add hickory chick weight 0.5 % neutral protease and 0.5% flavor protease, heat at 55°C and stir for 3 hours to hydrolyze, heat up to 90°C, heat for 15 minutes to inactivate the enzyme, and filter to obtain the hickory chick enzymatic solution.

[0072] Weigh 150g of hickory chick enzymatic solution, add 3g of xylose, 12g of glucose, and 1.3g of cysteine, mix well, adjust the pH to 7.0 with edible soda ash, and carry out Maillard reaction at 100°C for 60min to obtain Morel Maillard reaction solution.

[0073]The effect of the Maillard reaction on the morel seasoning base material was explored by taking the morel hydrolyzate and the heat reaction treatment group of morel enzymolyzate (only heating, no exogenous addition of Maillard reaction raw materials). The principal component a...

Embodiment 3

[0078] Preparation of hickory chick enzymatic hydrolyzate:

[0079] Weigh 30 g of dried morels, crush them and pass through a 40-mesh sieve, add 300 g of purified water, and homogenate to obtain the morel slurry. Use edible soda ash to adjust the pH of the hickory chick slurry to 6.5, add 0.15 g of neutral protease and 0.15 g of flavored protease, incubate at 55°C for 3 hours, inactivate the enzyme at 85°C for 10 minutes, and filter to obtain hickory chick enzymatic hydrolysis solution and hickory chick enzymatic hydrolysis scum.

[0080] Preparation of morel seasoning base:

[0081] Weigh 300g of hickory chick enzymolysis solution, add 10g of xylose, 25g of glucose, and 2.5g of cysteine, mix well, adjust the pH to 7.0 with edible soda ash, and keep it warm at 100°C for 60min to carry out Maillard reaction.

[0082] Take by weighing 300g of the obtained Morchella Maillard reaction solution, add glycine 2.4g, glutamic acid 1.2g, compound acid hydrolyzed vegetable protein seas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com