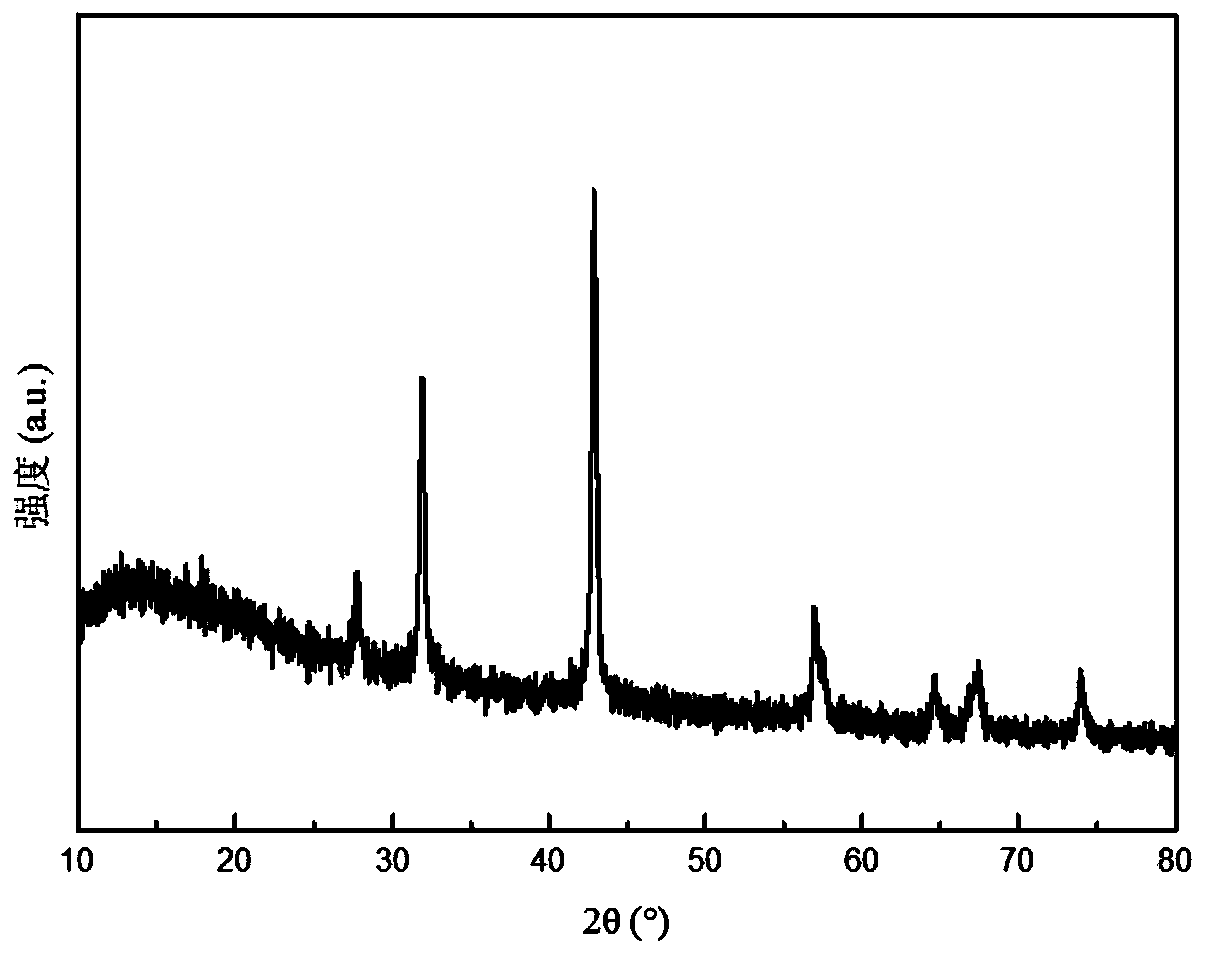

One-dimensional molybdenum phosphide nanorod and preparation method and application thereof

A technology of nanorods and molybdenum phosphide, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of difficult control of doping defects, poor material uniformity, cumbersome steps, etc., and achieve increased The effect of surface active sites, low production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the chemically synthesized molybdenum trioxide in the embodiment is:

[0041] Ammonium heptamolybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) be dissolved in the HNO that mass fraction is 65% 3 In the mixed solvent of solution and deionized water, a mixed solution is obtained, and the mass fraction is 65% HNO 3 The volume ratio of solution and deionized water is 1:5, and the mass concentration of ammonium heptamolybdate tetrahydrate in the mixed solution is 35g / L; Above-mentioned mixed solution is transferred in the stainless steel autoclave that is lined with Teflon, and in Heating at 200°C for 20h. After cooling, the product was collected by centrifugation, washed with water and ethanol, and then dried at 70°C overnight to obtain the obtained product.

Embodiment 1

[0043] A method for preparing a one-dimensional molybdenum phosphide nanorod, comprising the following steps:

[0044] Evenly disperse 0.1g of commercially available molybdenum trioxide powder and 0.09g of adenine in 30mL of deionized water to obtain a dispersion, transfer the resulting dispersion to a reaction kettle, heat to 110°C for hydrothermal reaction for 12h, and naturally cool to room temperature Finally, centrifuge at 4000rpm for 5min, wash the obtained product three times with deionized water and ethanol, and then dry at 80°C for 12h to obtain the molybdenum trioxide-adenine ribbon precursor.

[0045] Put the molybdenum trioxide-adenine ribbon precursor and sodium dihydrogen hypophosphite into quartz tubes at a mass ratio of 1:10, and transfer them to a high-temperature tubular atmosphere furnace. The quartz tube filled with sodium dihydrogen hypophosphite Be placed on the upstream of the nitrogen gas flow, the quartz tube that is equipped with molybdenum trioxide-a...

Embodiment 2

[0057] A method for preparing a one-dimensional molybdenum phosphide nanorod, comprising the following steps:

[0058] Evenly disperse 0.1g of commercially available molybdenum trioxide powder and 0.09g of adenine in 30mL of deionized water to obtain a dispersion, transfer the resulting dispersion to a reaction kettle, heat to 110°C for hydrothermal reaction for 12h, and naturally cool to room temperature Finally, centrifuge at 4000rpm for 5min, wash the obtained product three times with deionized water and ethanol, and then dry at 80°C for 12h to obtain the molybdenum trioxide-adenine ribbon precursor.

[0059] Put the molybdenum trioxide-adenine ribbon precursor and sodium dihydrogen hypophosphite into quartz tubes at a mass ratio of 1:10, and transfer them to a high-temperature tubular atmosphere furnace. The quartz tube filled with sodium dihydrogen hypophosphite Be placed on the upstream of the nitrogen gas flow, the quartz tube that is equipped with molybdenum trioxide-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com