High-purity silver nanowire and preparation method thereof, and silver nanowire conductive film

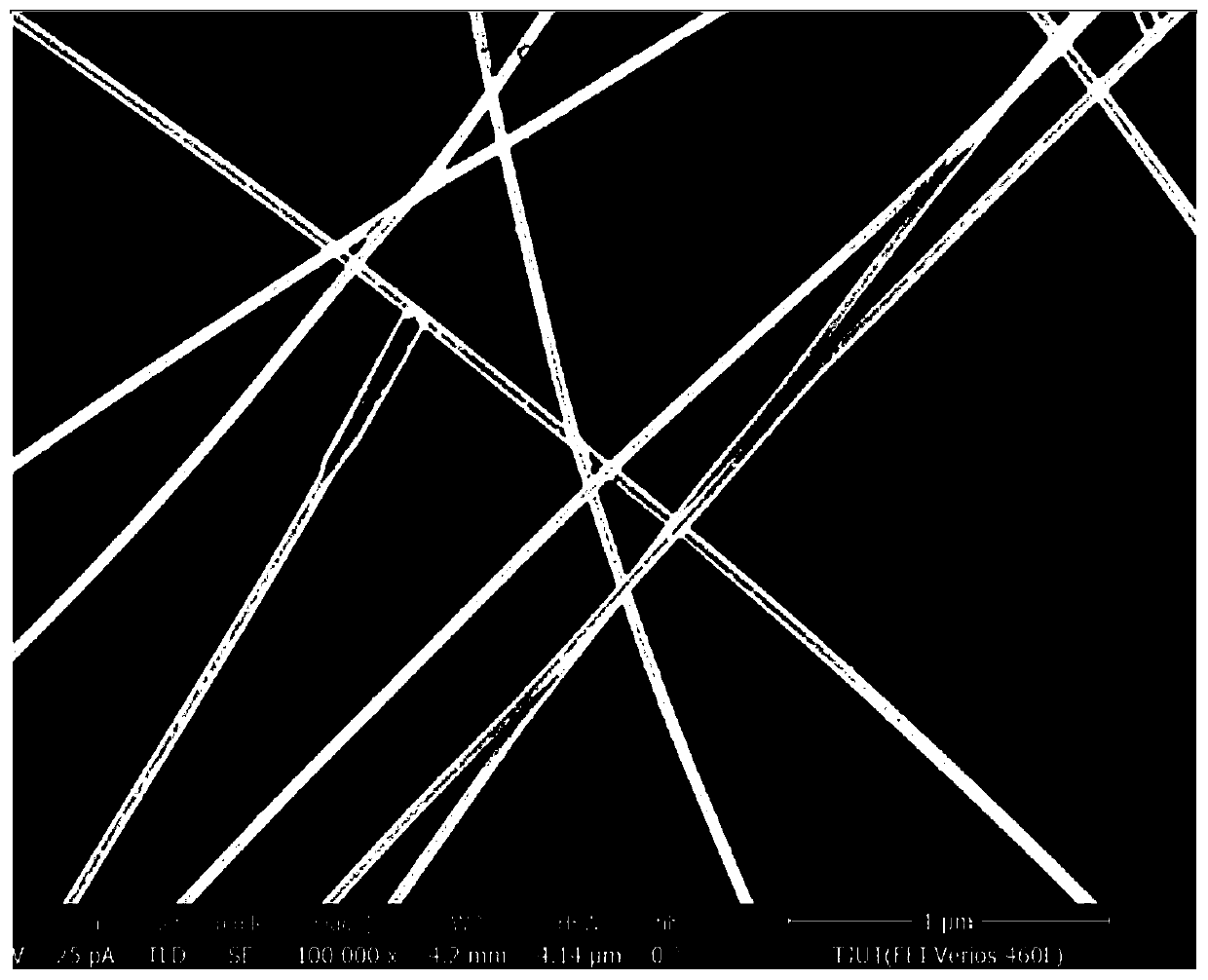

A silver nanowire, high-purity technology, applied in the field of nanomaterials, can solve the problems of silver nanowire purification difficulties, and achieve the effects of reducing atmospheric environmental pollution, high purity, and narrow diameter distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method for high-purity silver nanowires, comprising the following steps:

[0043] Step 1: Prepare the silver nanowire synthesis solution to be separated and purified

[0044] Measure 90ml of ethylene glycol with a measuring cylinder, add 0.38ml 0.01g / ml potassium bromide solution, 0.45ml 0.01g / ml potassium chloride solution, 0.25ml 0.01g / ml ferric chloride hexahydrate solution and 1.5g poly Vinylpyrrolidone, then start heating and stirring, reach 160°C and keep warm for 30min, then quickly add 10ml 0.1g / ml AgNO 3 solution, stop heating after reacting for 5 hours, and naturally cool to room temperature to obtain a silver nanowire synthesis liquid, the silver nanowire concentration is about 0.009g / ml. The above potassium bromide solution, potassium chloride solution, ferric chloride hexahydrate solution and AgNO 3 The solvent in the solution is ethylene glycol.

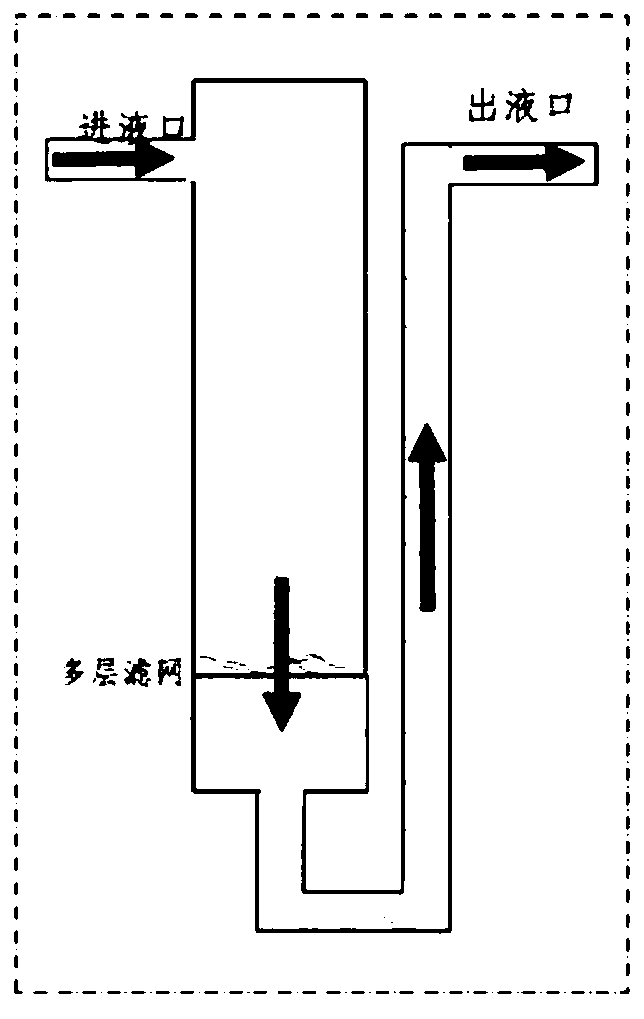

[0045] Step 2: Mix the silver nanowire synthesis solution obtained in step 1 with water at a ...

Embodiment 2

[0056] A preparation method of high-purity silver nanowires, comprising the following steps:

[0057] Step 1: Prepare the silver nanowire synthesis solution to be separated and purified

[0058] Measure 90ml of ethylene glycol with a graduated cylinder, add 0.38ml 0.01g / ml potassium bromide, 0.45ml 0.01g / ml potassium chloride, 0.25ml 0.01g / ml ferric chloride hexahydrate, 1.5g polyvinylpyrrolidone, Then start heating and stirring, reach 160°C and keep it warm for 30min, then quickly add 10ml 0.1g / ml AgNO 3 solution, stop heating after reacting for 5 hours, and naturally cool to room temperature to obtain a silver nanowire synthesis liquid, the silver nanowire concentration is about 0.009g / ml. The solvent used in the above solutions is ethylene glycol.

[0059] Step 2: The silver nanowire synthesis solution obtained in step 1 and ethanol are mixed at a volume ratio of 1:7, stirred at a speed of 400 rpm / min for 0.5 h, and then centrifuged at a centrifugal speed of 4500 rpm for ...

Embodiment 3

[0065] A preparation method of high-purity silver nanowires, comprising the following steps:

[0066] Step 1: Prepare the silver nanowire synthesis solution to be separated and purified:

[0067] Measure 90ml of ethylene glycol with a measuring cylinder, add 1.52ml 0.01g / ml potassium bromide, 0.45ml 0.01g / ml potassium chloride, 0.25ml 0.01g / ml ferric chloride hexahydrate, 1.5g polyvinylpyrrolidone, Then start heating and stirring, reach 160°C and keep it warm for 30min, then quickly add 10ml 0.1g / ml AgNO 3 solution, stop heating after reacting for 5 hours, and naturally cool to room temperature to obtain a silver nanowire synthesis liquid, the silver nanowire concentration is about 0.009g / ml. The solvent used in the above solutions is ethylene glycol.

[0068] Step 2: The silver nanowire synthesis solution obtained in step 1 and the mixed solvent (water:ethanol mixing volume ratio 1:1) were stirred at a speed of 1000 rpm / min for 5 h at a volume ratio of 1:4, and then centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com