Immobilized laccase and preparation method thereof, and application of immobilized laccase in antibiotic degradation

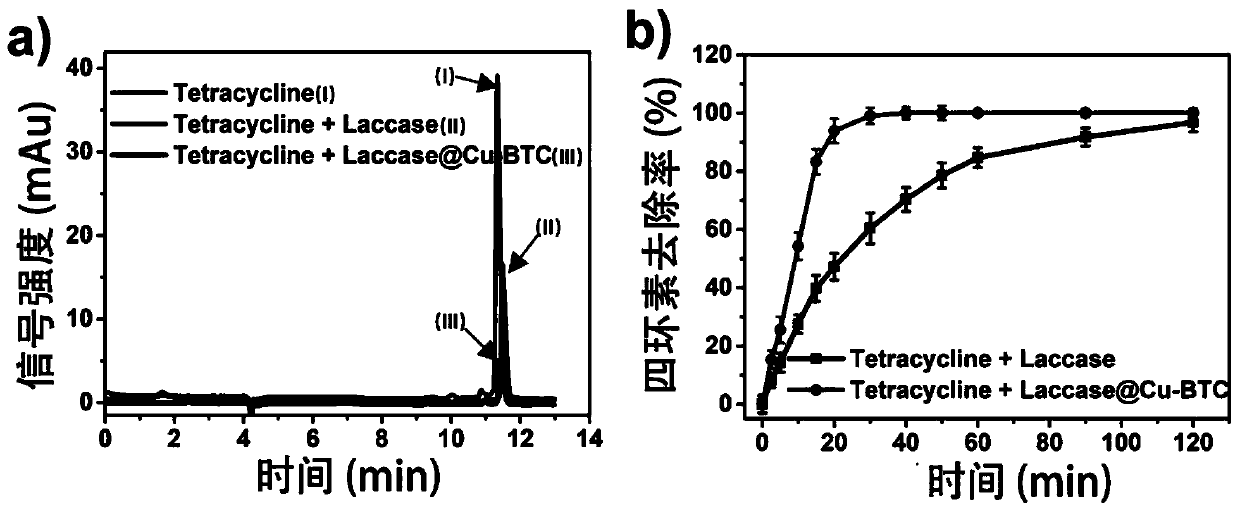

A technology for immobilizing laccase and laccase, applied in the direction of immobilization on or in inorganic carriers, on/in organic carriers, biochemical equipment and methods, etc., can solve the problems of low immobilization efficiency and enzyme activity Loss, instability and other problems, to achieve effective removal, improve enzyme activity, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for immobilized laccase, comprising the steps of:

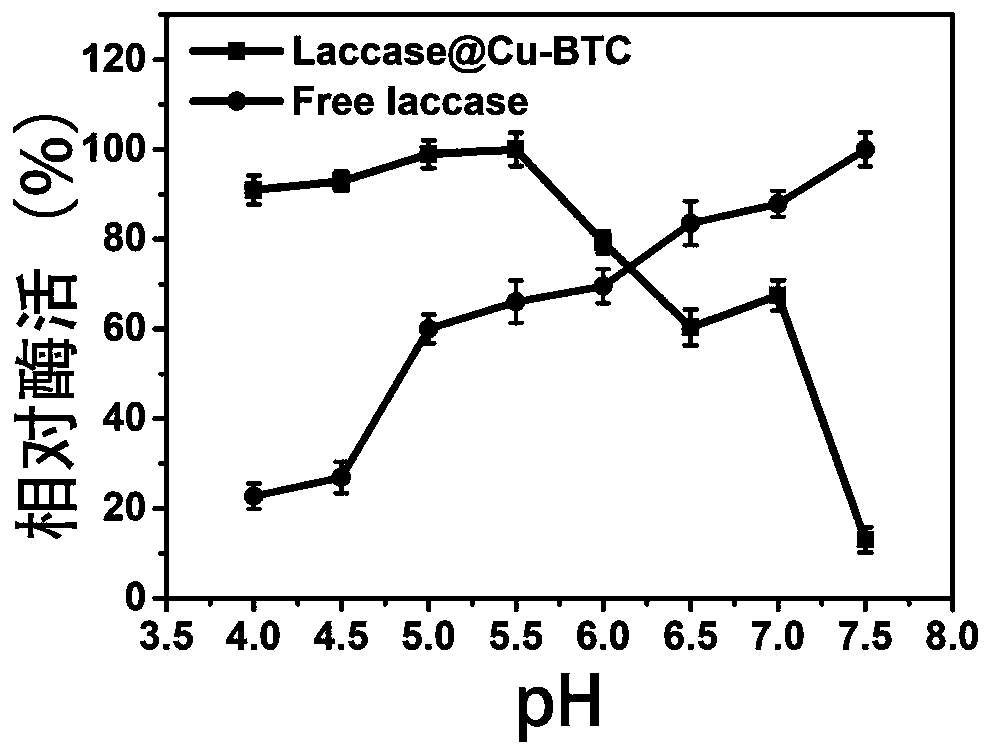

[0040] Add 2U laccase to 1 mL of 10 mM copper acetate solution (the solvent of the solution is citric acid buffer solution with pH=5.5) and mix well, then add 0.1 mL of 50 mM trimesic acid dimethyl sulfoxide solution , after mixing for 5 minutes, centrifuge at 1000 rpm for 10 minutes to remove the supernatant, resuspend and wash with water for 3 times, and dry in vacuo to obtain immobilized laccase (Laccase@Cu-BTC).

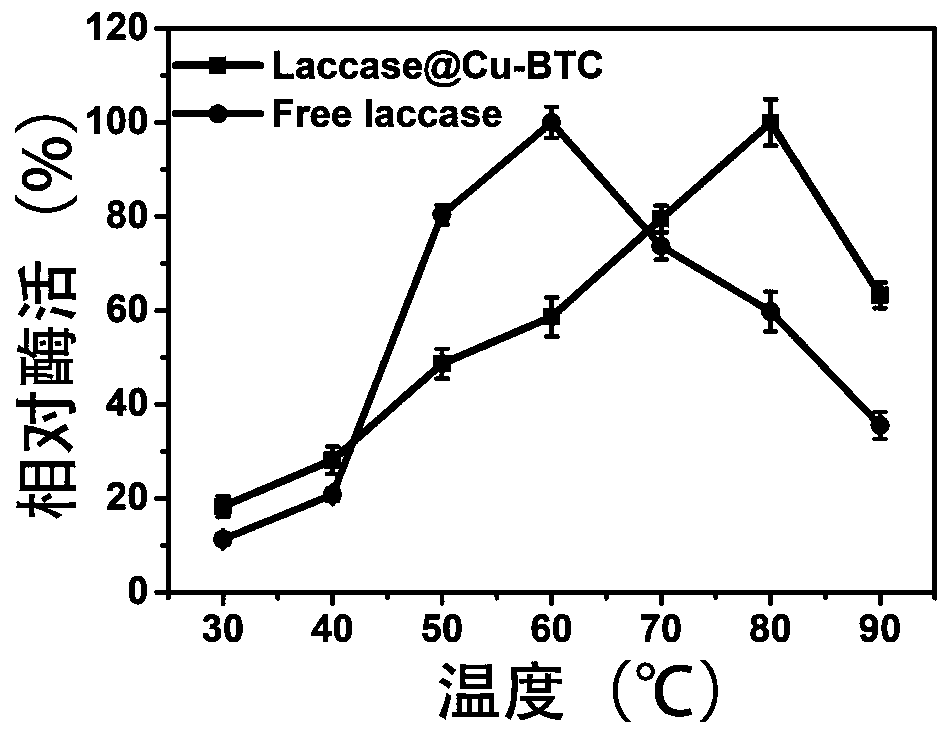

[0041] Weigh the dried solid, the solid mass is 20 mg, the enzyme loading of the immobilized carrier is 20 mg / g, and the enzyme activity is 13 U. In the case of the same amount of enzyme, the enzyme activity of the immobilized laccase is higher than that of the free enzyme Enzyme activity increased by 6.5 times.

[0042] On the determination of enzyme activity of free laccase and immobilized laccase and the calculation of laccase immobilization rate:

[0043] Take two parts of 2μg l...

Embodiment 2

[0051] A preparation method for immobilized laccase, comprising the steps of:

[0052] Add 2U laccase to 200mL of 0.5mM cupric chloride solution (acetic acid buffer with solvent pH=5.0) and mix evenly, then add 200mL of 0.5mM trimesic acid ethanol solution, mix Homogenize for 5 minutes, centrifuge at 1000 rpm for 10 minutes to remove the supernatant, resuspend and wash with pH=5.5 citrate buffer for 3 times, and dry in vacuo to obtain immobilized laccase (Laccase@Cu-BTC).

[0053] Weigh the dried solid, the solid mass is 30.5mg, the enzyme loading of the immobilized carrier is 13.1mg / g, and the total enzyme activity is 32U. Enzyme activity is 16 times higher than that of free enzyme.

Embodiment 3

[0055] An immobilization method for improving laccase activity, comprising the following steps:

[0056] Add 2U laccase to 150mL concentration of 5mM copper sulfate solution (solvent of this solution is glycine buffer solution with pH=5.5) and mix evenly, then add 10mL concentration of 15mM trimesic acid solution (solvent of this solution is Tris-HCl buffer solution with pH=7.8), after mixing for 5 minutes, centrifuge at 1000 rpm for 10 minutes to remove the supernatant, resuspend and wash the solid with acetic acid buffer solution with pH=5.5 for 3 times, and fix it after vacuum drying Laccase (Laccase@Cu-BTC).

[0057] The dried solid was weighed, the solid mass was 60.5mg, the enzyme load of the immobilized carrier was 6.7mg / g, and the total enzyme activity was 60U. The activity of the free enzyme is 30 times higher than that of the free enzyme.

[0058] Experiments have shown that water, pH=4.5 citric acid buffer, pH=7.0 citric acid buffer, pH=4.5 acetate buffer, pH=7.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com