Solid oxide fuel cell

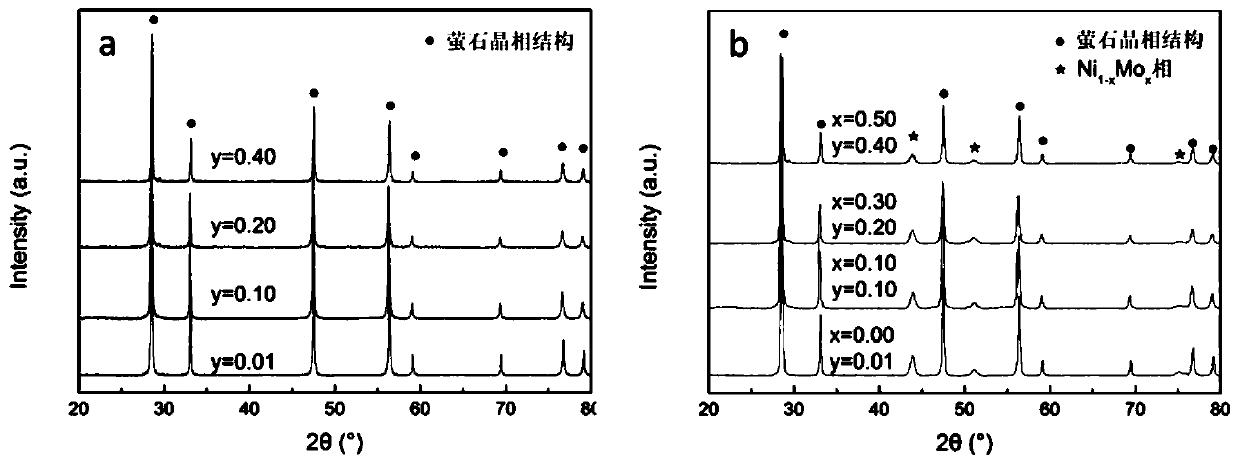

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve problems such as battery performance degradation and low degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

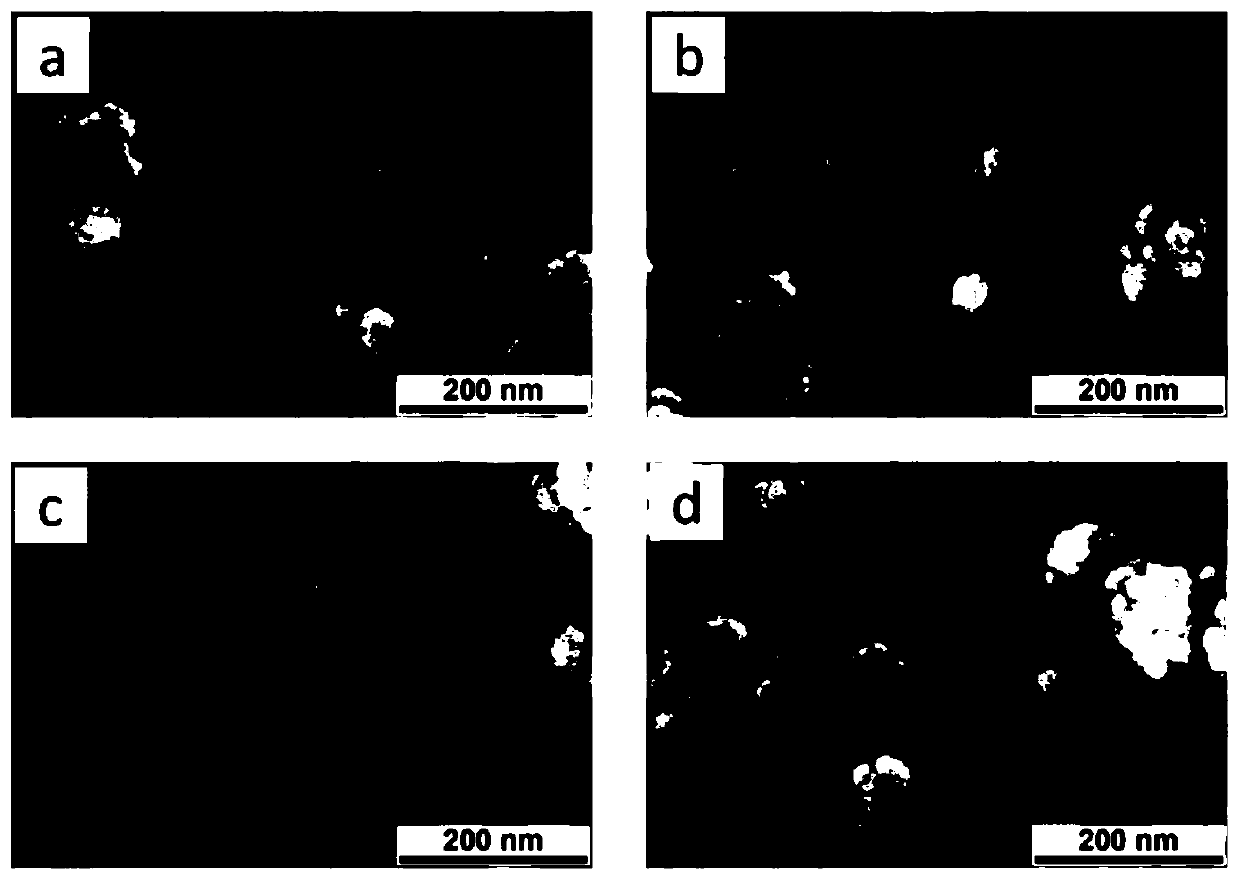

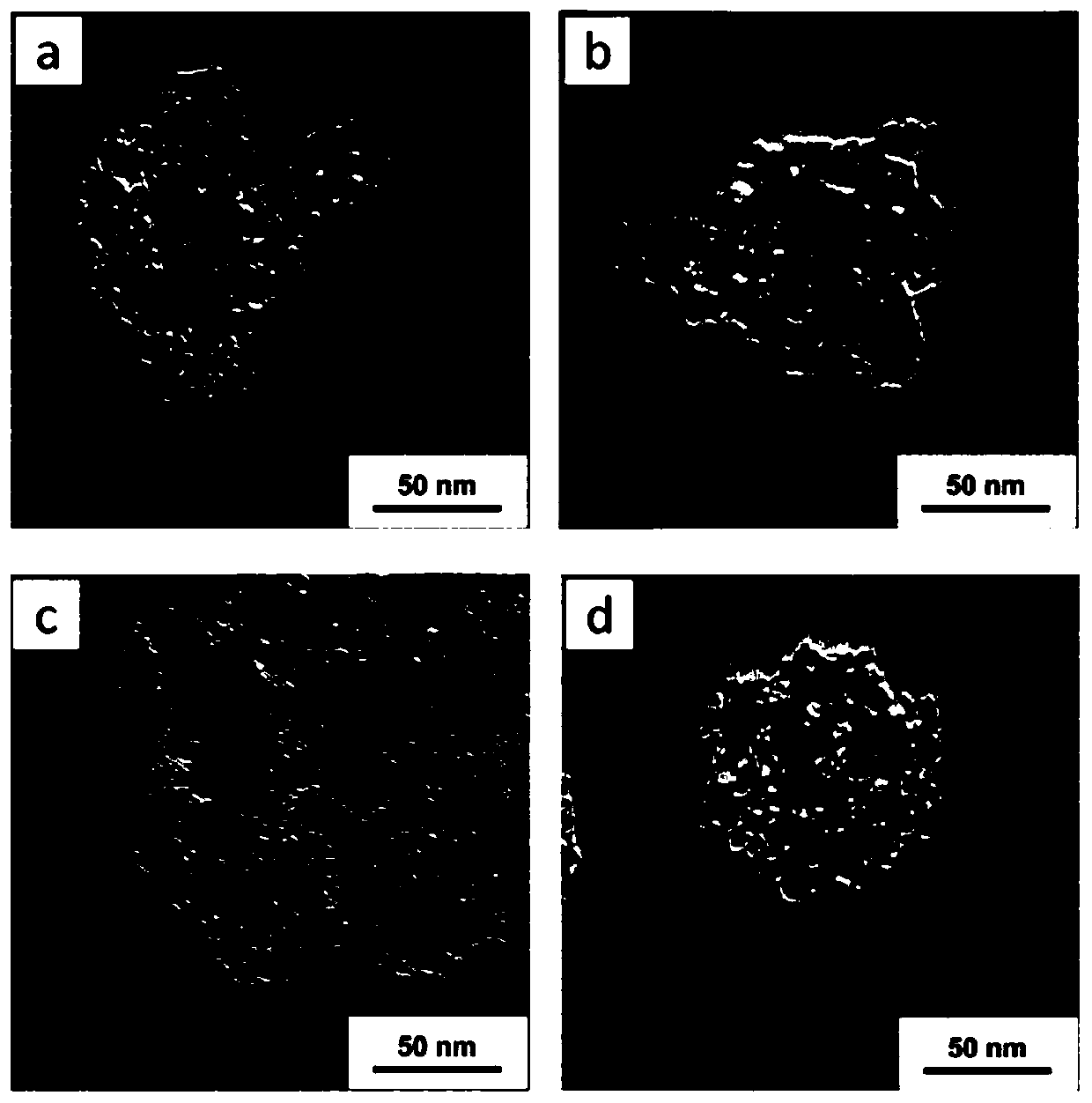

Examples

Embodiment approach B12

[0146] In the embodiments of B1-B24 of the present invention, the cathode is lanthanum strontium manganese oxide (such as B5, B6, etc.), lanthanum strontium cobalt iron oxide (such as B1, B2, etc.), barium strontium manganese oxide (such as B1, B2, etc.) One of cobalt iron oxides (B12, etc.). The general formula of lanthanum strontium manganese oxide is La 1-m Sr m MnO 3-δ , where 01- m Sr m MnO 3-δ , 01-a Sr a co 1-b Fe b o 3-δ , where 01-a Sr a co 1-b Fe b o 3-δ Among them, a=0.1-0.9, b=0.3-1.0 or a=0.2-0.8, b=0.2-1.0). Further, in embodiment B1 of the present invention, La 1-a Sr a co 1-b Fe b o 3-δ Among them, a=0.4, b=0.8. The composition formula of barium strontium cobalt iron oxide is Ba 1-a Sr a co 1-b Fe b o 3-δ , where 01-a Sr a co 1-b Fe b o 3-δ Among them, a=0.4, b=0.8.

[0147] The configuration is "Ni-yttria stabilized zirconia (YSZ) as the anode; YSZ / samarium doped ceria (SDC) as the electrolyte; La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com