Fuel cell anti-reversal catalyst and preparation method thereof

A catalyst and nano-catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of lack of precious metals, hindering the commercial application of proton exchange membrane catalyst layer additives, and high cost, to alleviate carbon carrier corrosion, easy to implement, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

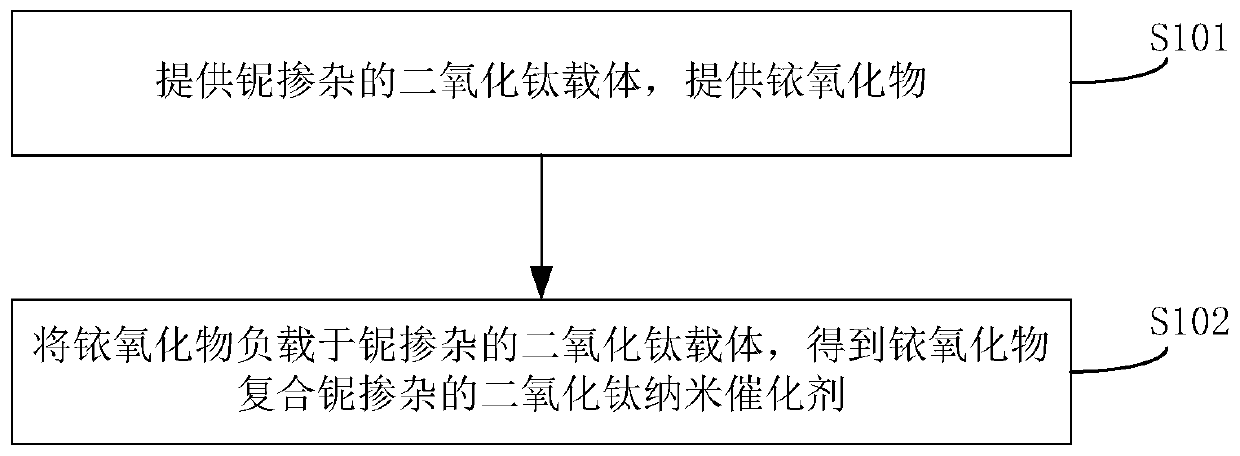

[0042] see figure 2 , figure 2 It is a schematic flow diagram of an embodiment of the preparation method of the anti-reversal catalyst of the present invention. It should be noted that the preparation method of the present invention can prepare the above-mentioned catalyst. For a detailed description of the relevant content, please refer to the content of the above-mentioned catalyst. Let me tell you more. The method includes:

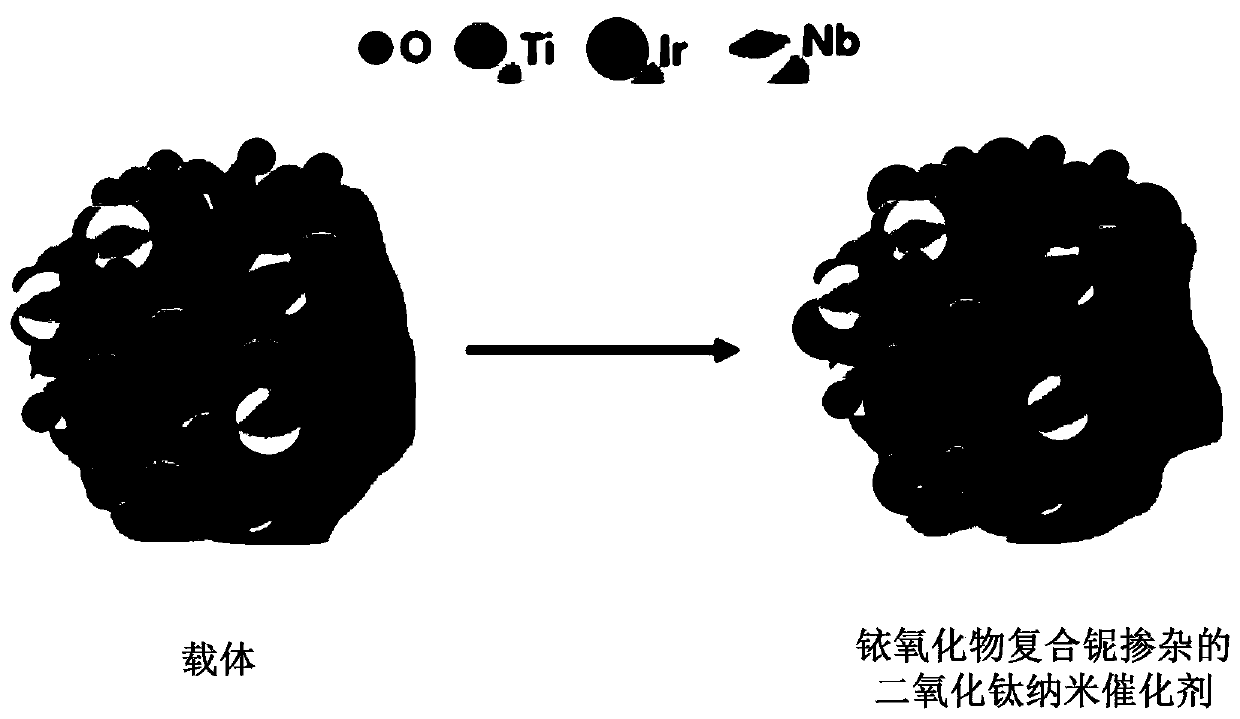

[0043] Step S101: providing a niobium-doped titania carrier and iridium oxide.

[0044] Step S102: Loading iridium oxide on a niobium-doped titania carrier to obtain an iridium oxide-composite niobium-doped titania nanocatalyst.

[0045] There are many existing methods and methods for providing niobium-doped titania carrier and iridium oxide, which will not be repeated here. The niobium-doped titania carrier and the iridium oxide are mixed together, and the iridium oxide composite niobium-doped titania nanometer catalyst can be prepared through r...

Embodiment 1

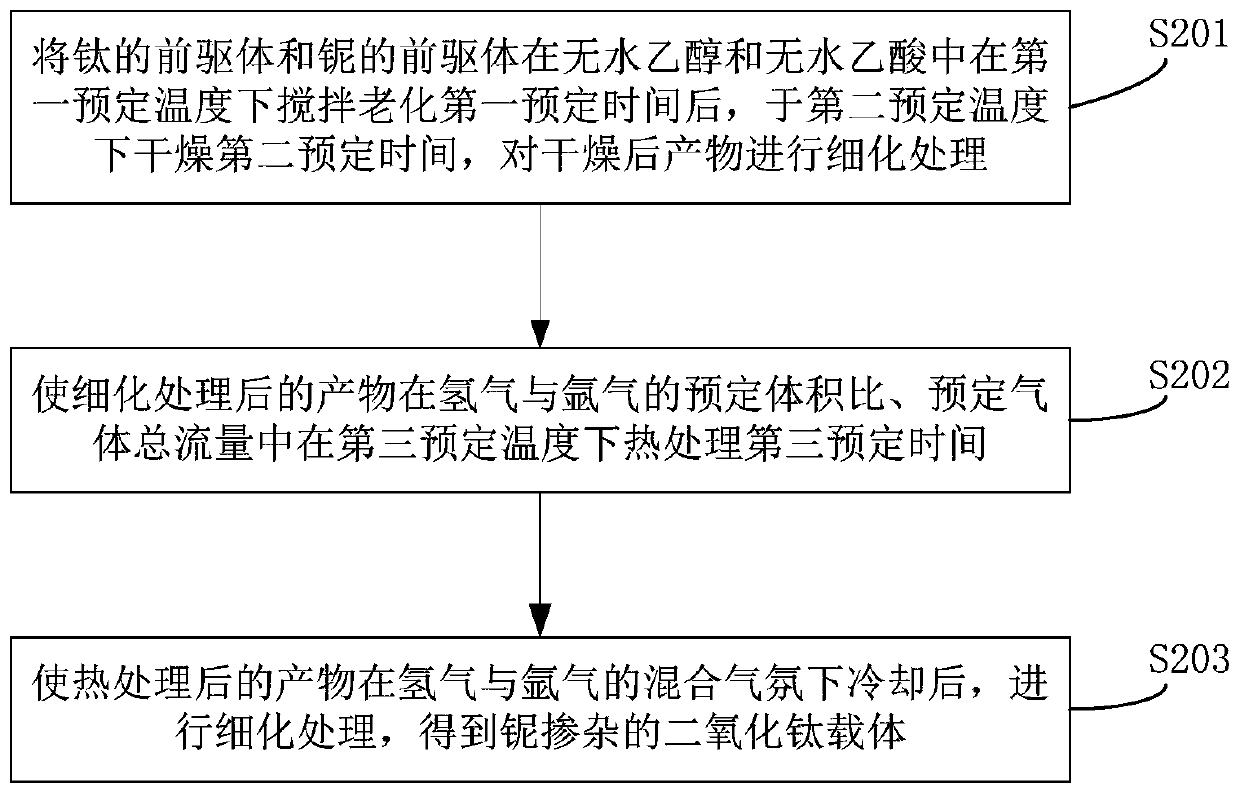

[0071] (1)Nb 0.05 Ti 0.95 o 2 Preparation of the carrier:

[0072] Add 10mL of anhydrous acetic acid into 40mL of absolute ethanol and stir for 5min, add 10.62mL of tetraisopropyl titanate and 0.4738mL of niobium ethoxide to the above solution, stir and age at 80°C for 12h, then dry in an oven at 120°C for 2h, grind Refinement, heat treatment at 700°C for 4 hours in a mixed atmosphere with a hydrogen:argon volume ratio of 1:8, and a total gas flow rate of 500mL / min, then naturally cool in a mixed atmosphere, take out the sample, grind and refine, and obtain the carrier Nb 0.05 Ti 0.95 o 2 .

[0073] (2) 20% loading of IrOx loaded on Nb 0.05 Ti 0.95 o 2 Preparation of the catalyst:

[0074] Measure 19.23mL IrCl 3 solution, add 30mL ethylene glycol, ultrasonically disperse for 20min, stir for 40min, add 2M NaOH solution to the above solution to adjust the pH to 12, then add 0.8g Nb 0.05 Ti 0.95 o 2 , vigorously stirred for 1 h, and the above reactant was refluxed at...

Embodiment 2

[0076] (1)Nb 0.2 Ti 0.8 o 2 Preparation of the carrier:

[0077] Add 10mL of anhydrous acetic acid into 40mL of absolute ethanol and stir for 5min, add 10.62mL of tetraisopropyl titanate and 2.2505mL of niobium ethoxide to the above solution, stir and age at 80°C for 12h, then dry in an oven at 120°C for 2h, grind Refinement, heat treatment at 700°C for 4 hours in a mixed atmosphere with a hydrogen:argon volume ratio of 1:8, and a total gas flow rate of 500mL / min, then naturally cool in a mixed atmosphere, take out the sample, grind and refine, and obtain the carrier Nb 0.2 Ti 0.8 o 2 .

[0078] (2) 20% loading of IrOx loaded on Nb 0.2 Ti 0.8 o 2 Preparation of the catalyst:

[0079] Measure 19.23mL IrCl 3 solution, add 30mL ethylene glycol, ultrasonically disperse for 20min, stir for 40min, add 2M NaOH solution to the above solution to adjust the pH to 12, then add 0.8g Nb 0.2 Ti 0.8 o 2 , vigorously stirred for 1 h, and the above reactant was refluxed at 140° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com