Molecularly imprinted silica gel polymer and preparation method and application thereof

A technology of molecular imprinting and polymers, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems affecting the number and stability of complexes, and the decrease of molecular imprinting efficiency, so as to improve the efficiency of molecular imprinting and increase production safety , to avoid heating or cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

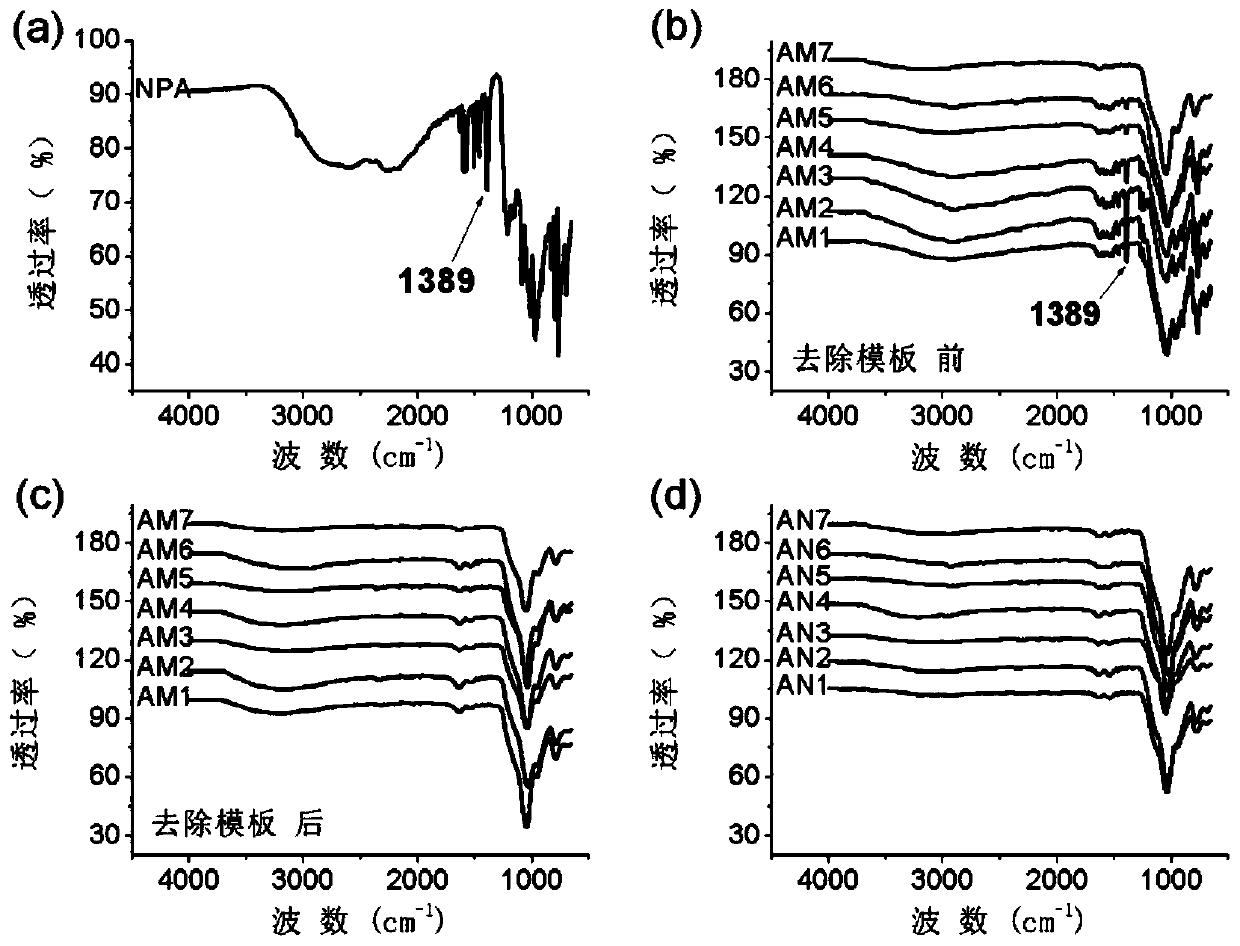

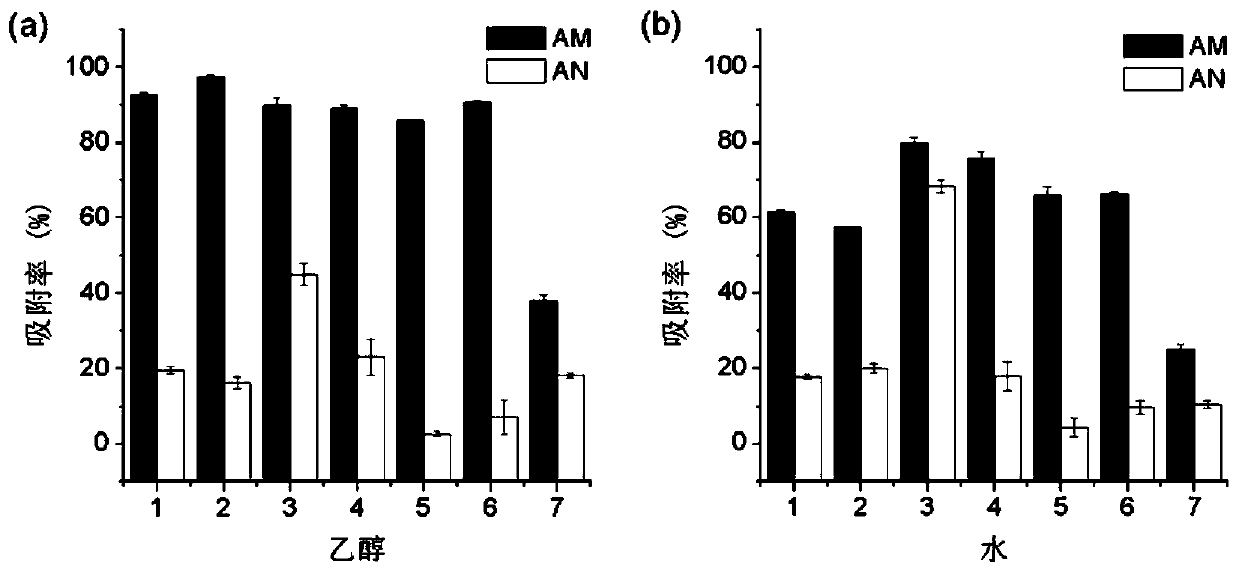

[0029] In this embodiment, the functional monomer is 3-aminopropyl-triethoxysilane, the crosslinking agent is tetraethoxysilane, the template molecule is 1-naphthalene phosphoric acid, the solvent is a mixture of water and ethanol, and the eluting solution It is a phosphate buffer (10 mM, pH 8.5).

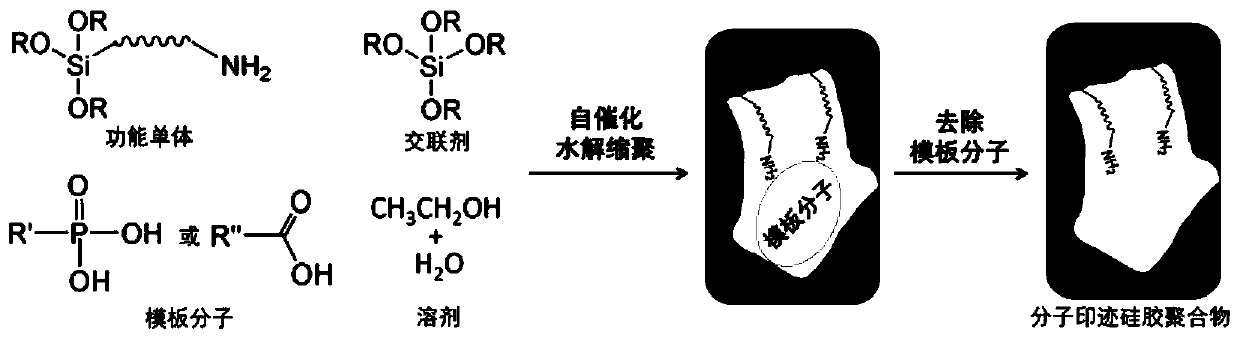

[0030] For the preparation method of the molecularly imprinted silica gel polymer, see figure 1 , including the following steps:

[0031] Step 1. Take 56mg of 1-naphthylphosphonic acid, 117μL of 3-aminopropyl-triethoxysilane (APTES), 1mL of tetraethoxysilane (TEOS), 20mL of water and 12mL of ethanol to form the molecularly imprinted prepolymer solution In the reaction vessel (50mL round bottom flask);

[0032] Step 2. At room temperature, react the molecularly imprinted pre-polymerization solution in the reaction vessel with magnetic stirring (500r / min) for 24 hours to obtain a polymer, remove the unreacted liquid by centrifugation, and then wash the polymer with ethanol Three t...

Embodiment 2

[0036] Same as Example 1, the difference is that in the first step, 56 mg of 1-naphthylphosphonic acid, 117 μL of 3-aminopropyl-triethoxysilane (APTES), 1 mL of tetraethoxysilane (TEOS), 12 mL of water and 20 mL of Molecular imprinting pre-polymerization solution formulated with ethanol was added to the reaction vessel (50 mL round bottom flask).

[0037] The molecularly imprinted silica gel polymer prepared in this example is named AM2. The yield of AM2 prepared was 10%.

Embodiment 3

[0039] Same as Example 1, the difference is that in the first step, 56 mg of 1-naphthylphosphonic acid, 117 μL of 3-aminopropyl-triethoxysilane (APTES), 1 mL of tetraethoxysilane (TEOS), 1 mL of water and 31 mL of Molecular imprinting pre-polymerization solution formulated with ethanol was added to the reaction vessel (50 mL round bottom flask).

[0040] The molecularly imprinted silica gel polymer prepared in this example is named AM3. The yield of AM3 was prepared in 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com