A kind of method that utilizes fly ash to prepare multi-level porous ZSM-5 molecular sieve

A technology of ZSM-5 and fly ash, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., which can solve the problems of high impurities, low yield and crystallinity, limited diffusion speed, etc. problems, to achieve the effect of accelerating mass transfer rate, reducing economic cost and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

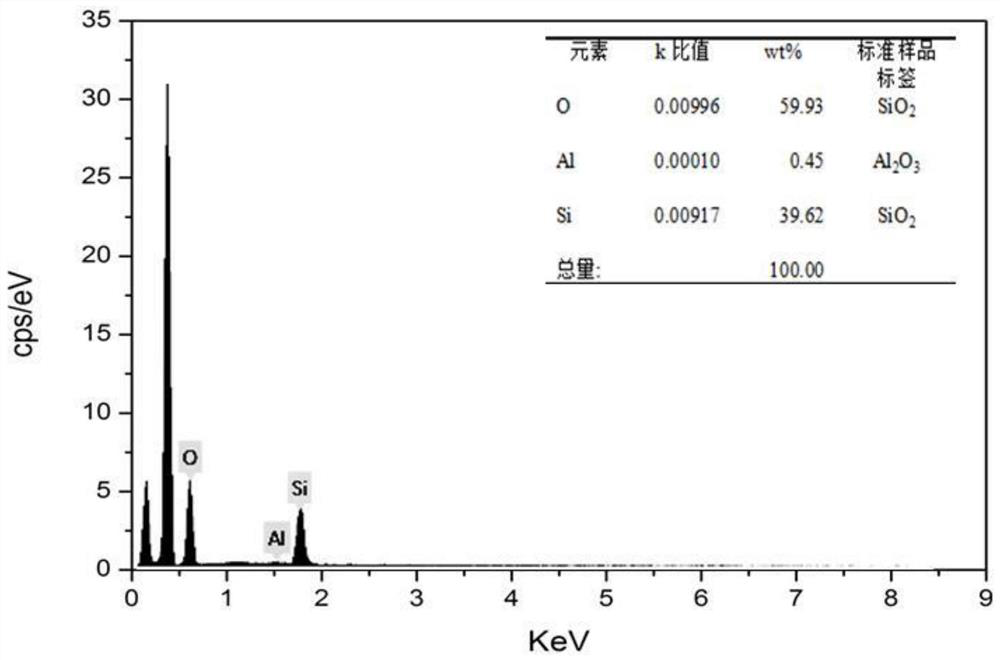

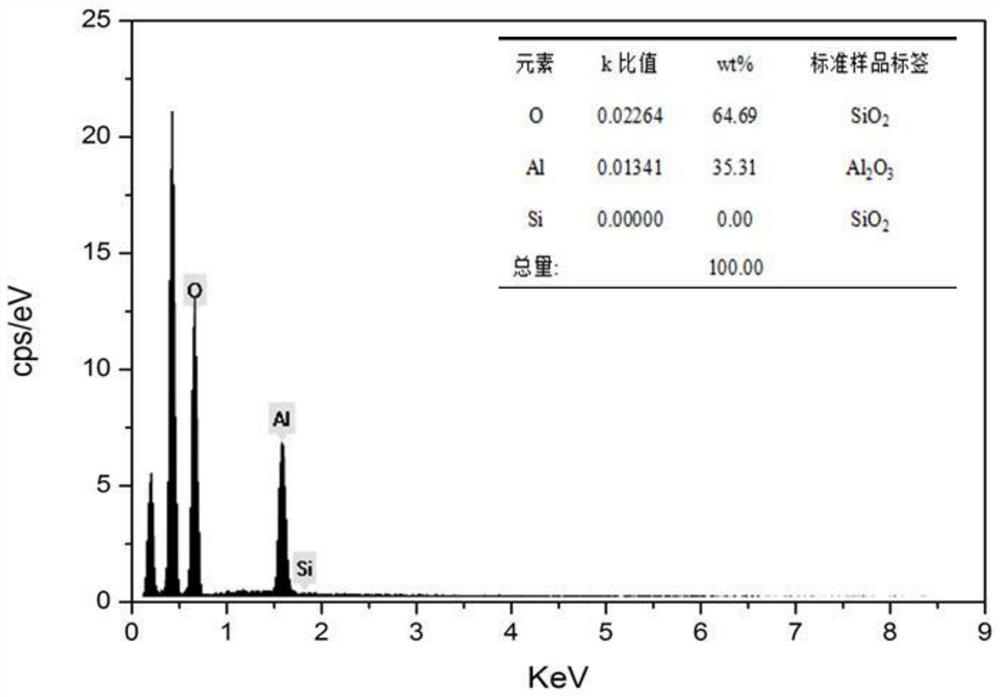

[0039] After calcination of 200 g of fly ash at 800 ° C, after cooling, 2000 ml of distilled water was stirred and washed 12h, filtered, dried, add 1,60 g of sodium carbonate, sufficiently ground, then put it into the muffle oven at 900 ° C Calcination 4h After cooling, calcination is calcined, and the calcined ripe as ash is laurel green, and the calcined as gray grinds the 200 mesh sieve, adding 1600 ml of 15 wt% hydrochloric acid, stirred at 80 ° C for 2 h, cooling, filtration, respectively collect the filtrate and filter residue, Filter residue was washed repeatedly to neutral, dry after drying, 650 ° C calcined 2H SiO 2 Spare, weighing 92.08g. The filtrate was added to the separatory funnel, and then the extractant was added to the separatory funnel, the volume ratio of the filtrate and the extractant was 0.8: 1, the extractant is a mixture of tributyl phosphate and benzene, and the phosphoric acid The volume ratio of butyl ester and benzene is 1: 3, and the solution in the s...

Embodiment 2

[0047] SiO 2 Al (OH) 3 Extraction method as in Example 1.

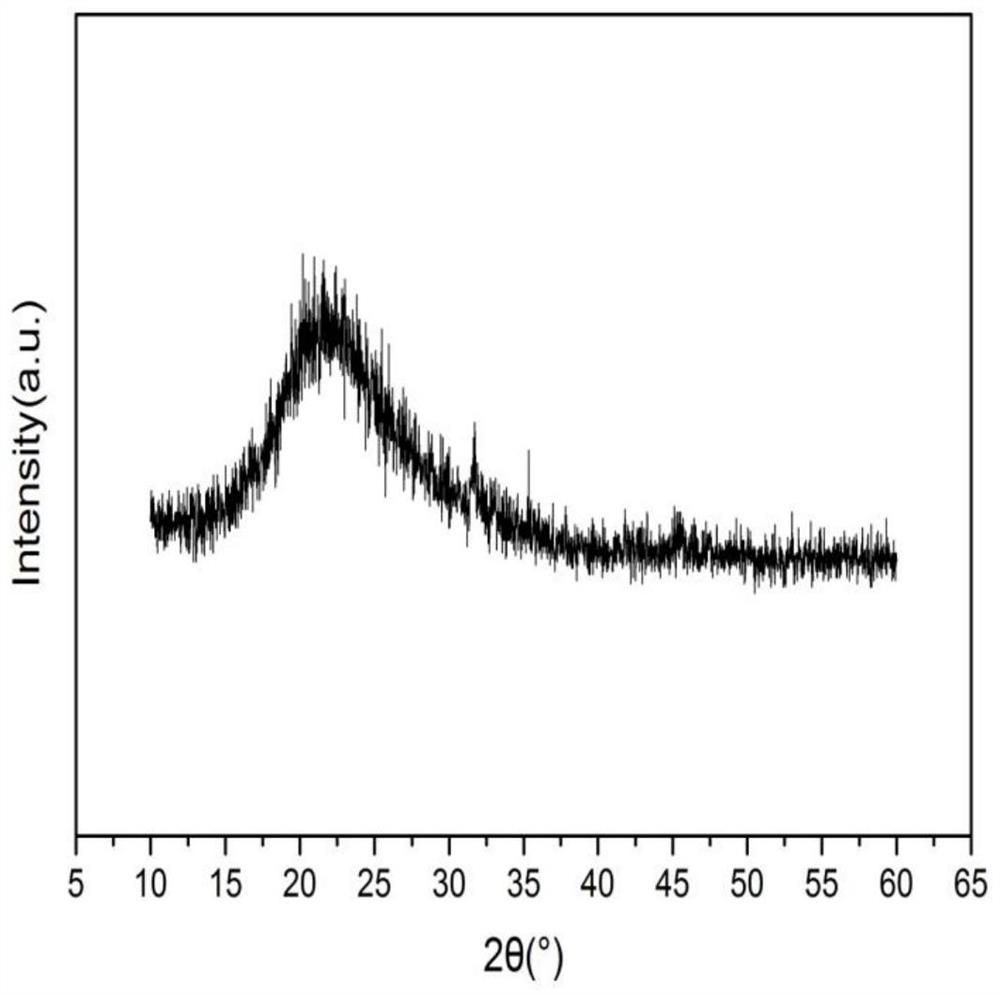

[0048] Use SiO extracted from fly ash 2 Al (OH) 3 Synthetic multi-level hole ZSM-5 molecular sieves, the use of raw material Moore ratio: SiO 2 : Al (OH) 3 : NaOH: TPABR: CTAB: H 2 O = 1: 0.017: 0.35: 0.17: 0.05: 50, according to the above-mentioned ratio, the microporous template TPABR is added to the single-mouth flask, and then the deionized water is dissolved, then sodium hydroxide provides a certain amount of alkaline environment. After dissolving, add the SIO extracted from fly ash. 2 Al (OH) 3 After stirring for 30 min, the mesh template CTAb was added, and the mixture was heated at 60 ° C, stirred 24 h to obtain gel-like substance, and the gel-like substance was shifted into the reactor with polytetrafluoroethylene liner 140. Crystallization 24 h, cooled, filtered, washed, dried, dried, and dried, dried to a muffle furnace 550 ° C.

[0049] from Figure 11 and Figure 12 As shown in the XRD and SEM map of the NA-ZSM...

Embodiment 3

[0051] SiO 2 Al (OH) 3 Extraction method as in Example 1.

[0052] Use SiO extracted from fly ash 2 Al (OH) 3 Synthetic multi-level hole ZSM-5 molecular sieves, the use of raw material Moore ratio: SiO 2 : Al (OH) 3 : NaOH: TPABR: CTAB: H 2 O = 1: 0.0125: 0.25: 0.17: 0.05: 50, according to the above-mentioned ratio, the microporous template TPABR is added to the single-mouth flask, and then the deionized water is dissolved, then sodium hydroxide is added to provide a certain basic environment. After dissolving, add the SIO extracted from fly ash. 2 Al (OH) 3 After stirring for 30 min, the mesh template CTAb was added, and the mixture was heated at 60 ° C. The gel-like substance was stirred, and the gel-like substance was moved into the reactor with the polytetrafluoroethylene liner. 180 Crystallization 48h, cooling, filtration, water washing, drying, 550 ° C for 2 h removing the template agent to obtain a Na-ZSM-5 molecular sieve.

[0053] from Figure 15 and Figure 16 As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com