Garden waste composting process and composting product prepared by same

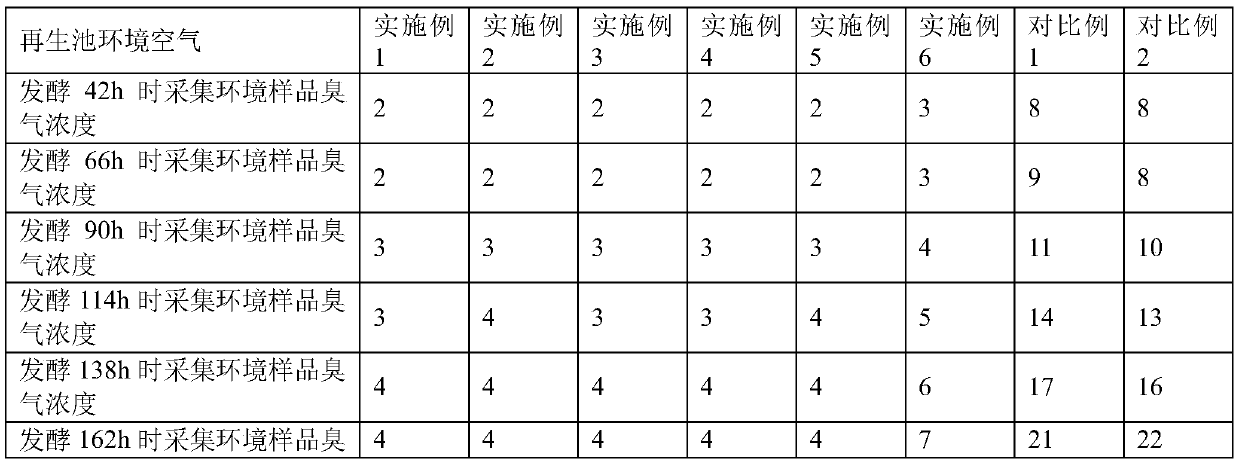

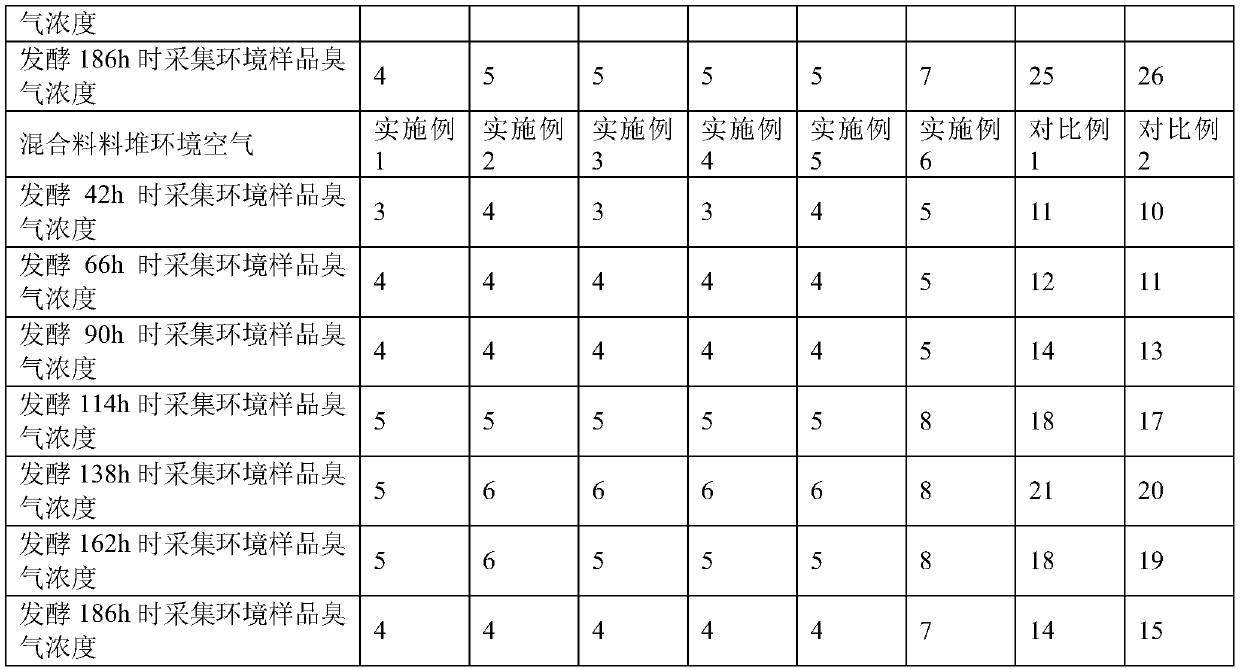

A garden waste and process technology, applied in the field of garden waste composting process and its prepared composting products, can solve the problems of production environment pollution, harsh production environment, affecting the surrounding air and living environment of the production plant, and achieve reduction effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

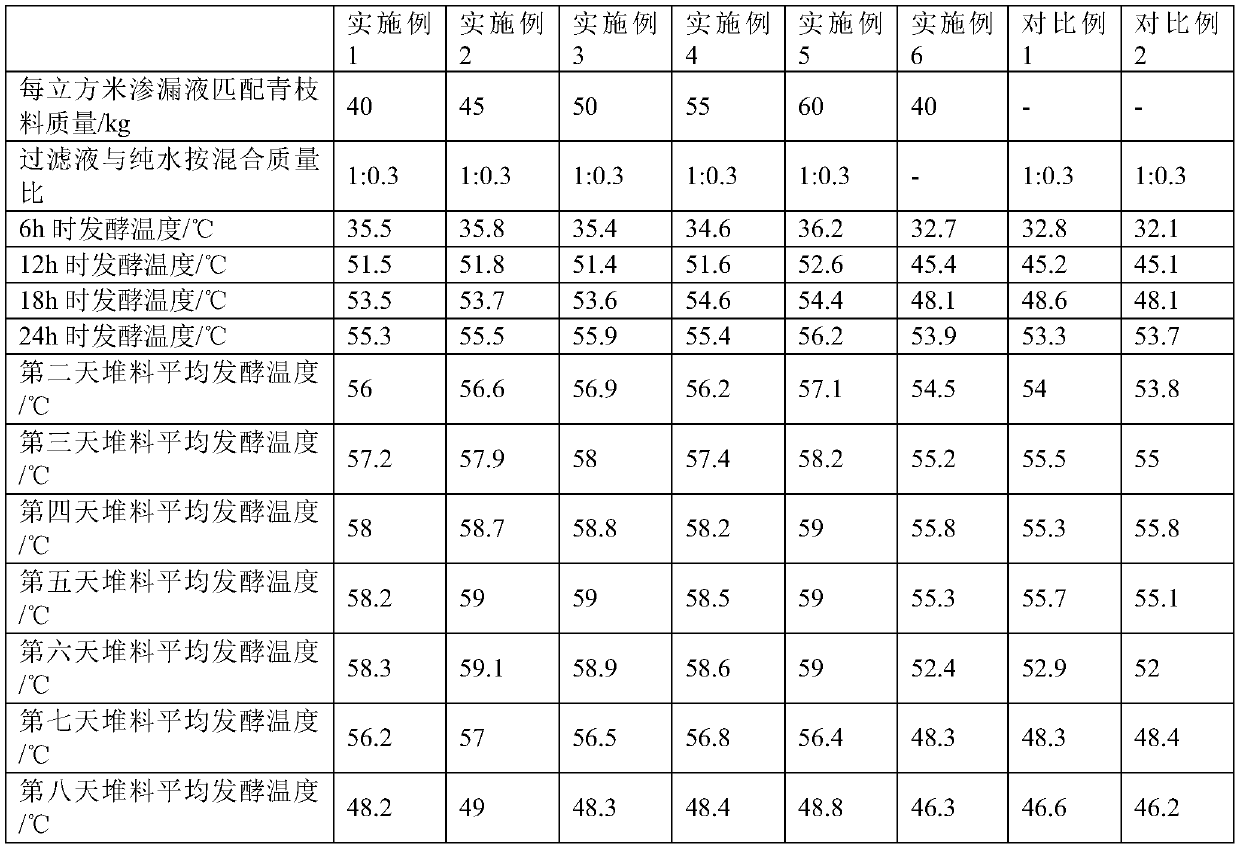

Examples

Embodiment 1

[0036] A kind of garden waste composting technology, it comprises the following steps:

[0037] S1: Prepare raw materials in parts by mass, 75 parts of garden waste, 10 parts of chicken manure, 8 parts of synergist, and 0.5 part of decomposing agent. Effect agent" and decomposing agent are commercially available products of Beijing Jiabowen Biotechnology Co., Ltd. "organic material decomposing agent";

[0038] S2: Mix the garden waste, chicken manure, synergist, and decomposing agent weighed in S1 evenly to obtain a mixture, stack the mixture in a pile with a ground diameter of 2m and a height of 1.5m, and spray from top to bottom Sprinkle with water to adjust the moisture content in the mixture to 50-60wt%;

[0039] S3: The mixture is stacked and left still, and the water content of the mixture is detected every 30 minutes. The moisture content is less than 50wt%, and the water is sprayed on the pile to replenish water until the mixture reaches 50-60wt%;

[0040] S4: During...

Embodiment 2

[0045] A kind of composting process of garden waste, based on the basis of embodiment 1, per cubic meter of seepage liquid is matched with 65kg green sticks for production.

Embodiment 3

[0047] A kind of composting process of garden waste, based on the basis of embodiment 1, every cubic meter of seepage liquid is matched with 75kg green sticks for production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com