Metal surface oxidation-resistant high-temperature glue and preparation method thereof

A high-temperature glue, metal surface technology, used in adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc. problem, to achieve the effect of good high temperature resistance, improve the degree of mixing, and improve the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

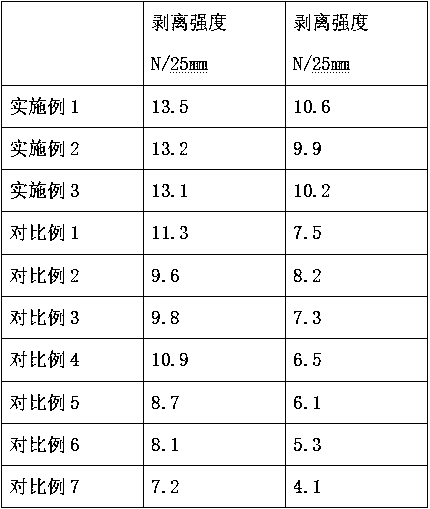

Examples

Embodiment 1

[0022] A metal surface oxidation-resistant high-temperature glue, its components include: A component: lithium silicate, potassium fluorosilicate, sodium silicate, polyphosphoric acid, water; B component: polyvinyl alcohol, silane coupling agent, Magnesium oxide, anhydrous calcium chloride; C component: potassium dihydrogen phosphate, 3000 mesh mesoporous carbon, perfluoroalkyl vinyl ether. The mass ratio of lithium silicate, potassium fluorosilicate, sodium silicate, polyphosphoric acid and water in component A is 3:2:7:0.7:10. In the B component: the mass ratio of polyvinyl alcohol, silane coupling agent, magnesium oxide and anhydrous calcium chloride is 12:3:3:2. In the C component: the mass ratio of potassium dihydrogen phosphate, 3000 mesh mesoporous carbon, and perfluoroalkyl vinyl ether is 2:8:3. The mass ratio of the A component, the B component, and the C component is 3:5:1.5. The specific surface area of the 3000 mesh mesoporous carbon is 2500m 2 / g. The silane...

Embodiment 2

[0027] A metal surface oxidation-resistant high-temperature glue, its components include: A component: lithium silicate, potassium fluorosilicate, sodium silicate, polyphosphoric acid, water; B component: polyvinyl alcohol, silane coupling agent, Magnesium oxide, anhydrous calcium chloride; C component: potassium dihydrogen phosphate, 3000 mesh mesoporous carbon, perfluoroalkyl vinyl ether. The mass ratio of lithium silicate, potassium fluorosilicate, sodium silicate, polyphosphoric acid and water in component A is 2:3:6:0.8:10. In the B component: the mass ratio of polyvinyl alcohol, silane coupling agent, magnesium oxide, and anhydrous calcium chloride is 10:4:2:3. In the C component: the mass ratio of potassium dihydrogen phosphate, 3000 mesh mesoporous carbon, and perfluoroalkyl vinyl ether is 1:10:2. The mass ratio of the A component, the B component, and the C component is 4:4:2. The specific surface area of the 3000 mesh mesoporous carbon is 2500m 2 / g. The silane...

Embodiment 3

[0032] A metal surface oxidation-resistant high-temperature glue, its components include: A component: lithium silicate, potassium fluorosilicate, sodium silicate, polyphosphoric acid, water; B component: polyvinyl alcohol, silane coupling agent, Magnesium oxide, anhydrous calcium chloride; C component: potassium dihydrogen phosphate, 3000 mesh mesoporous carbon, perfluoroalkyl vinyl ether. The mass ratio of lithium silicate, potassium fluorosilicate, sodium silicate, polyphosphoric acid and water in component A is 4:1:8:0.6:10. In the B component: the mass ratio of polyvinyl alcohol, silane coupling agent, magnesium oxide, and anhydrous calcium chloride is 14:2:4:1. In the C component: the mass ratio of potassium dihydrogen phosphate, 3000 mesh mesoporous carbon, and perfluoroalkyl vinyl ether is 3:6:4. The mass ratio of the A component, the B component, and the C component is 2:6:1. The specific surface area of the 3000 mesh mesoporous carbon is 2500m 2 / g. The silane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com